Chemical manufacturing presents unique challenges, such as the need to trace lots, manage compliance with OSHA and FDA regulations, and keep track of changing formulations. In today’s competitive business climate, every advantage you can gain in terms of efficiency affects your bottom line. You probably already have software systems in place, but your financial, customer, and operations data may be siloed in different systems, making it difficult to quickly gain accurate insights into your overall operations or to adjust to changing customer needs.

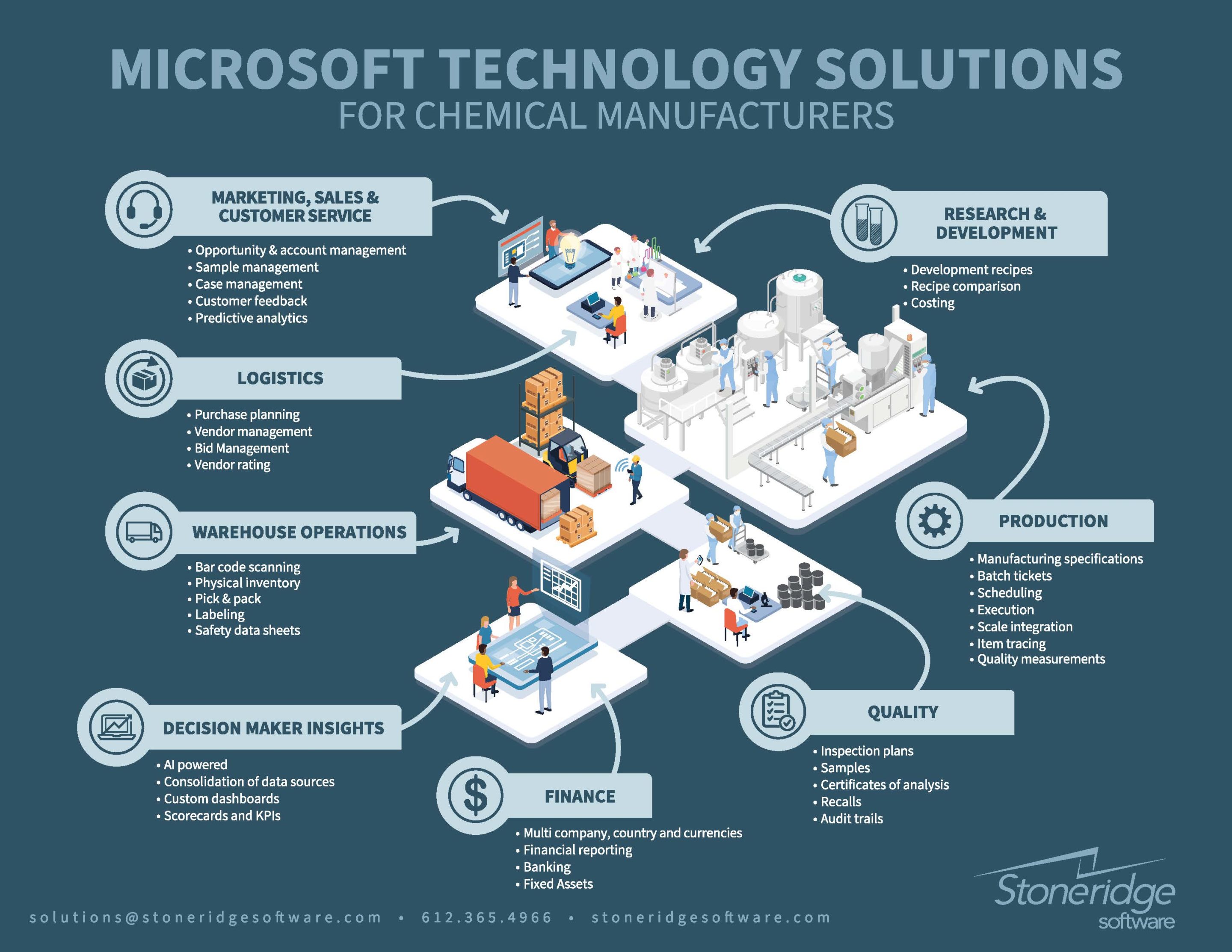

The experts at Stoneridge Software can partner with you to implement a complete, customized, and tightly integrated enterprise resource planning (ERP) and customer relationship management (CRM) solution using Microsoft Dynamics 365 and industry-specific chemical ERP manufacturing software, such as YAVEON ProBatch.

Stoneridge’s consultants and technical experts can create a Dynamics 365 deployment that matches your company’s needs.

Learn how we can partner together.

Contact Us TodayMicrosoft Dynamics for Chemical Manufacturing

Microsoft Dynamics 365 offers a modular suite of cloud-based software-as-a-service (SaaS) business applications that can connect data, processes, and teams across your business to increase your company’s efficiency, productivity, and adaptability.

You can set up a system with only the modules your company needs and scale your usage as your business grows. Because Dynamics 365 is built on Microsoft Azure, the tech giant’s cloud infrastructure service, you can also eliminate the need for on-premises infrastructure and information technology (IT) administration.

An added bonus is that Dynamics 365 seamlessly integrates with the familiar Office applications included in Microsoft 365. Imagine accessing information from your CRM system directly within Microsoft Outlook, and you’ll have an idea of the power of this level of integration and how it can enhance your chemical manufacturing operation. Stoneridge Software can partner with you to implement Dynamics 365 and customize it to match the needs of your business.

What Is Chemical Manufacturing?

Chemical manufacturing is a broad designation that covers everything from the production of agricultural products to pharmaceuticals to soap and other cleaning supplies.

Some chemical manufacturing operations produce large quantities of commodity chemicals using continuous processing. Batch-processing chemical engineering companies often produce limited quantities of customized products for their customers. Regardless of the methods or markets involved, chemical manufacturing operations are complex.

The Need for an ERP and CRM

You probably already have systems in place to handle your financials, supply chain, operations and processes, and human resources. But are your systems integrated or siloed? How easily does information flow from one area of your business to another?

An ERP system can help you manage many difficult aspects of the chemical manufacturing process, like batch tracing, compliance with FDA and OSHA regulations, storage of hazardous chemical raw materials, and changing product formulations.

A CRM system can help you manage sales, service, marketing, and financials and provide you with up-to-the-minute customer insights. The true power of such modern software suites is most evident when you combine ERP and CRM into one integrated system.

Suppose a customer wants a new formulation of a product. If you implement Microsoft Dynamics 365 for your ERP and CRM needs, you have instant access to the customer’s history and can quickly see whether you have the raw materials on hand, gauge material costs, and have an idea how quickly the order can be fulfilled. Chemical manufacturing operations thrive and grow when they have this kind of information flow and agility.

Why Invest in Microsoft Dynamics?

Microsoft Dynamics 365 is a modular, cloud-based SaaS solution for ERP and CRM systems. You can manage the cost of your implementation by only using modules that apply to your business and paying only for the number of users you need. You can easily scale up as your business grows by adding users, and you can quickly adapt to changing business conditions by adding or removing modules as needed.

Dynamics 365 as a Chemical Manufacturing ERP

If you need an ERP for chemical manufacturing, you can select the Microsoft 365 applications that apply specifically to your industry. Relevant applications include:

- Microsoft 365 Business Central

- Microsoft 365 Project Operations

- Microsoft 365 Supply Chain Management

Some chemical software companies produce industry-specific ERP software. Stoneridge can facilitate a Dynamics 365 deployment for your company that integrates tightly with an ERP solution for chemical and pharmaceutical manufacturers called YAVEON ProBatch.

ProBatch works with Dynamics 365 Business Central to provide solutions for quality control and lot traceability, necessities for lot management for chemical batch manufacturers.

Dynamics 365 as a Chemical Manufacturing CRM

Dynamics 365 also offers a number of applications for CRM, including (but not limited to):

- Dynamics 365 Sales

- Dynamics 365 Customer Service

- Dynamics 365 Marketing

- Dynamics 365 Customer Insights

- Dynamics 365 Customer Voice

How Stoneridge Helps Implement Dynamics 365

One paramount consideration in adopting an ERP solution is your implementation partner. Deploying accounting and operations software is not for the faint of heart. Migrating and integrating disparate systems and customizing applications to your business requires deep knowledge of both your business and the ERP software.

The experts at Stoneridge have decades of experience deploying ERP systems. In addition, Stoneridge has achieved Microsoft Business Partner status, awarded only to companies that have demonstrated a high level of technical expertise in implementing Microsoft products. When you partner with Stoneridge, we’re with you for the long haul; we’ll not only walk with you through the implementation stage, but we’ll also be there for you as you use your ERP system. Contact us to start a conversation about how Stoneridge can help with your ERP needs.

Choosing the Right Chemical Manufacturing Software

When it comes to choosing the right chemical manufacturing software for your business, there are many things to consider. Implementing Dynamics 365 Business Central with YAVEON ProBatch gives you an integrated solution with all the basic needs of an ERP plus a slate of added features designed specifically for the chemical manufacturing industry.

There are a number of advantages to a Dynamics 365–based ERP system:

- Breadth of application offerings: Microsoft is top-ranked for the breadth of its ERP applications.

- Industry-leading cloud platform and security: Microsoft Dynamics 365 is built on Microsoft’s Azure platform, a top choice for cloud-based IT infrastructure.

- Integration with Microsoft 365 Office applications: You may already use Office apps like Word, Excel, and Outlook; imagine your team accessing up-to-the-minute customer insights from within the Outlook email client.

- Integration with Microsoft Dynamics 365 CRM solutions: Eliminating data silos and interconnecting every area of your business gives you strategic insight into how you can boost your company’s efficiency and productivity.

- Integration with chemical-industry-specific ERP applications like YAVEON ProBatch

Reach out to Stoneridge today for more information on implementing Microsoft Dynamics 365 ERP and CRM solutions for your chemical manufacturing business.

Stoneridge Software Treats You Like a Partner

Stoneridge Software is more than just a software company; we’re your partner in your chemical manufacturing ERP journey. Stoneridge doesn’t disappear after your implementation goes live. We will work with you shoulder to shoulder to ensure that you get the best return on your investment.

Contact Stoneridge to start a conversation about chemical batch manufacturing with Dynamics 365.

Contact UsStart the Conversation

It’s our mission to help clients win. We’d love to talk to you about the right business solutions to help you achieve your goals.