Midwest Rubber Aligns Future Business Goals with Dynamics 365 Business Central as Foundation for Operations

As Midwest Rubber expanded over the years, the leadership team found themselves with multiple Made2Manage ERP systems making it difficult to compare or consolidate data from their different locations.

When they began their search for a new ERP solution, Midwest Rubber knew they needed a solution that would bring their entire business onto one consolidated platform, give them better visibility to data, and reduce manual entry and processes. Initially, they were drawn to Dynamics NAV and began their implementation project with Stoneridge Software.

One component of an ERP implementation project with Stoneridge is a complete business process evaluation that examines processes, data, systems, and roles within the current structure of the business. During this stage, the team began to recognize the future goals of the business did not align with what an on-premises solution could provide. The leadership team, guided by Stoneridge Software, decided to pivot and instead look to cloud-based Dynamics 365 Business Central to serve as the foundation of their business software.

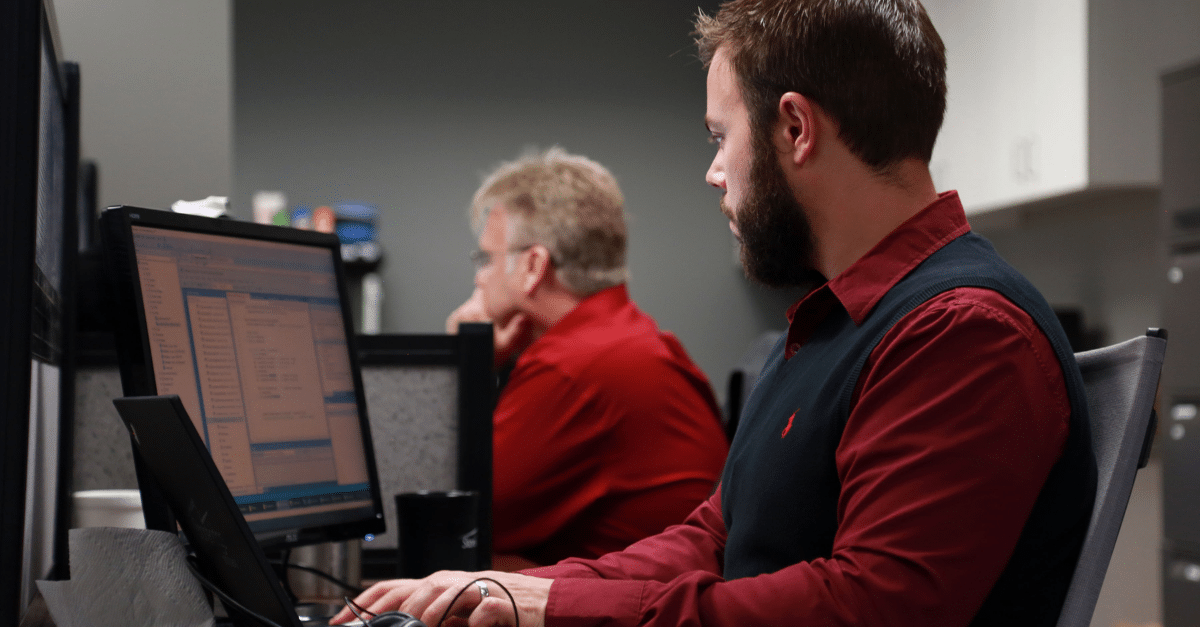

Impact on IT

With Business Central, the IT team at Midwest Rubber was able to shift focus and resources away from hardware and managing servers, offloading overhead and enabling Microsoft to bear the burden of ongoing security. Additionally, they no longer needed to plan and budget for timely and costly software upgrades every year. With two major releases annually and several smaller releases, updates are automatically applied to the system with little impact on the IT department and no impact on the budget.

User Training and Adoption

One of the most important components of the initial implementation was user training and adoption. The team at Stoneridge worked with the Midwest Rubber project team to develop documentation of internal processes, generate new training materials, and establish an in-house structure. In the train the trainer approach, a subject matter expert was appointed that is the go-to for any user issues or questions. Anything that cannot be answered by that in-house expert could then be escalated to the support team at Stoneridge.

The transfer of knowledge from the implementation team empowered all users to learn and feel comfortable with the system, giving them the tools they needed for immediate and ongoing success in their roles.

Finances

Business Central includes robust financial management capabilities out of the box that empowers users on day one. The entire sales process is completed within Business Central and thanks to an integration with Simcrest, invoices are automatically emailed from the system, adding yet another time saving process.

Additionally, Charge Logic was included to provide easy, secure, and reliable electronic payment processing. Charges are automatically settled when sales orders are shipped.

Tax Management

Changing tax requirements and regulations were cumbersome to manage and calculate. CCH SureTax was integrated into Business Central that provides automatic calculations of taxes in real-time, maintains tax exemption information, determines tax rates, rules, and jurisdictional boundaries, and helps manage overall sales tax compliance.

Data and Reporting

Data was standardized across the board, so no matter the location, there was a single core chart of accounts with standard dimensions. With this single structure, data can easily be compared and viewed in real-time.

Prior to implementing Dynamics 365 Business Central, users were unable to generate a list of customers on their own and were required to call technical experts at their software provider to gather the information. Now they can easily compile data based on thousands of different data points within the system – all on their own.

Jet Reports, an add-on solution that integrates directly into Business Central, was implemented to provide fast, flexible financial and business reporting with no manual processes required. The reports can be exported directly into Excel, where they can be viewed, updated, and shared while all information continues to flow back and forth between the report and Business Central, ensuring the information is always up to date.

The team at Midwest Rubber is continuing to develop production reports in order to measure throughput, gauge efficiency levels on the production floor, evaluate projected v. actual time to produce and more.

Manufacturing

Automated processes were implemented into the manufacturing process that reduced manual, time consuming activities and empowered employees to focus on production. The system was configured to automatically create and manage production orders, additionally controls were put in place to make production approval and closing processes more efficient.

Shop floor employees are now able to view full production orders and find information without having to log into Business Central, simplifying the information they have access to. Additionally, production quality is automatically monitored so if materials outside of a certain threshold are consumed, or a certain production time frame is taking longer than usual, managers are notified. This automated system helps both efficiency and accuracy of products manufactured.

Warehouse and Shipping

The supply chain management component of Business Central added functionality for advanced warehousing that optimized shipping, receiving, inventory management, and warehouse management.

Scanner guns were implemented throughout the warehouse. Now all items and bins are equipped with barcodes so warehouse employees know exactly what is in the warehouse and where each and every item is located.

A custom shipping queue was developed to speed the shipping process while ensuring order accuracy. Prior to implementing Dynamics, employees processed shipments in one system, then manually reentered all tracking numbers and shipping charges into their ERP solution. Now they have a fully integrated solution that automatically inputs tracking numbers on invoices and adds any charges. Additionally, UPS and Fedex shipping options were integrated directly into the system with Dynamic Ship, allowing users to access all shipping information and options from one system.

With Dynamics 365 Business Central in place, Midwest Rubber has a modern platform to grow their business that meets their needs now and well into the future.

Have Any Questions?