Revolutionizing Sugarbeet Sampling at Minn-Dak Farmers Cooperative: A Power App Project

Minn-Dak Farmers Cooperative (MDFC), a prominent player in the sugarbeet industry and the first sugarbeet cooperative in the United States, had embarked on a broad initiative to enhance their shareholder accounting system. Collaborating with Microsoft Partner Stoneridge Software, a recognized leader in innovative technology solutions, MDFC tackled the project on many fronts. One key focus was on the development of two Microsoft Power Platform applications – a Canvas App and a Model-Driven App. These apps were designed to streamline the gathering, tracking, and analysis of sugarbeets, replacing antiquated manual and Excel-intensive methods. This case study delves into the challenges of sugarbeet sampling faced by MDFC and collaborating with Stoneridge Software to transform their sampling process, contributing to increased operational efficiency and data accuracy.

Overcoming Manual and Excel-Dependent Sugarbeet Sampling Processes

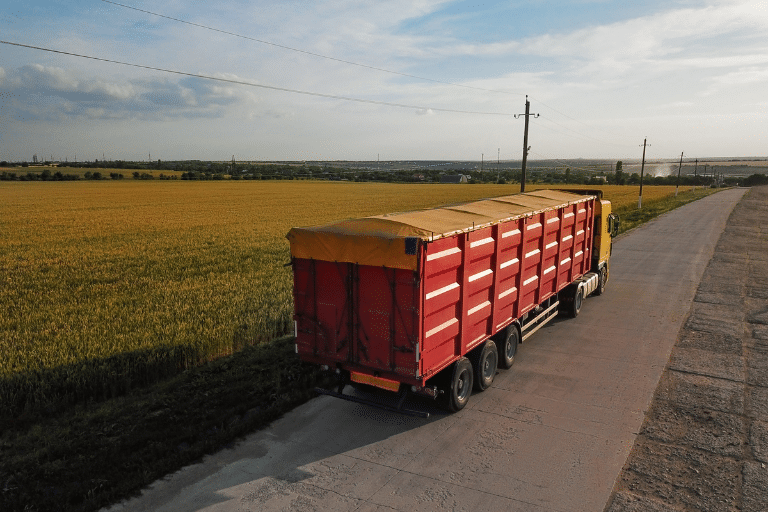

Situated in Wahpeton, ND, Minn-Dak Farmers Cooperative is owned by approximately 430 Shareholders and over 100 Growers, collectively tending to more than 105,000 acres of sugarbeets. MDFC faced challenges with their manual and Excel-dependent sugarbeet sampling process. Antiquated pen-and-paper methods resulted in operational complexity, a lack of real-time data entry, and difficulty in tracking and analyzing yield details. There was a clear need for a more efficient and integrated approach to improve the overall user experience for Agronomists.

Empowering Efficiency with Power Platform Apps

Partnering with Stoneridge Software, the proposed solution for Minn-Dak Farmers Cooperative leveraged the Microsoft Power Platform to address the challenges in their sugarbeet sampling process. Applications that are part of Power Platform are known for a no-code, low-code building process. The Power Platform solution at MDFC involved two key components: a Canvas App and a Model-Driven App. A Canvas App, typically built for mobile or tablets and internal use within an organization, was meticulously crafted to facilitate swift and efficient on-site data entry, empowering Agronomists to seamlessly conduct the process of “bagging and tagging” in the field.

On the other hand, the Model-Driven App, designed for desktop versatility, served as a robust tool for compiling comprehensive lists of growers and managing the entirety of the sampling process and its reporting elements with ease and effectiveness. These Power Platform applications played a pivotal role in replacing manual and Excel-intensive processes, providing a more streamlined, integrated, and user-friendly approach to sugar beet sampling and data management.

Power Platform Canvas App for On-Site Efficiency:

- Crafted for on-site data entry, enabling Agronomists to swiftly “bag and tag” in the field.

- Streamlined and user-friendly interface for a more efficient data capture experience.

Power Platform Model-Driven App for Desktop Versatility:

- Empowers users to efficiently compile comprehensive lists of growers and manage the entirety of the sampling process and its reporting elements with ease and effectiveness.

- Versatile tool designed for ease of use within the desktop environment.

Data Integration for Accuracy:

- Seamless data import method tailored to the Quality Lab’s file type for efficient and accurate lab result incorporation.

- Real-time data entry and lab result imports for enhanced accuracy in yield details and quality information.

Historical Reference for Long-Term Analysis:

- Establishment of a foundation for future reporting and analysis by storing historical data within Microsoft Dataverse.

- Elimination of manual data manipulation and management of multiple files for a streamlined process.

Transformative Impact on Agricultural Operations

Goals Achieved:

- Simplified Interface

- Replaced pen-and-paper methods with a user-friendly interface, reducing operational complexity.

- Marked enhancement in overall user experience.

- Results and Impact

- Revolutionized Minn-Dak’s sampling process with real-time data entry and tracking.

- Reduced reliance on manual processes for improved efficiency.

- Efficiency

- Agronomists can efficiently compile lists and conduct on-site sampling, minimizing time and effort.

- Data Accuracy

- Real-time data entry and lab result imports enhance the accuracy of yield details and quality information.

Stoneridge Software and MDFC worked together to successfully deliver a Power Platform solution that not only met functional requirements but also transformed MDFC’s sampling process. The Canvas and Model-Driven Apps provide a seamless and efficient way to gather, track, and analyze sugarbeet samples, contributing to increased operational efficiency and data accuracy. The project’s success is evident in the simplified interface, streamlined processes, and the elimination of manual data handling, leading to a positive impact on MDFC’s agricultural business operations.