An Introduction to Enterprise Asset Management in Dynamics 365 Finance and Operations for Commodity Processors

Enterprise Asset Management (EAM) in Dynamics 365 Finance and Operations can help track and maintain assets vital to commodity processors like yourself.

With this ability, you can:

- Leverage information to generate maintenance reports and work order

- Drive preventative maintenance and the generation of work orders from the preventative maintenance schedule

- Take associated costs and post the value to the general ledger

For example, if you are doing a work order for a trailer that you can repair internally and need to purchase a new part for it, you can just purchase that part and assign it to that asset. You can also have that as a fixed asset that you depreciate as part of your depreciation process.

Simply put, it can help you get the most out of your Dynamics 365 Finance and Operations system.

How Enterprise Asset Management Can Help Commodity Processors

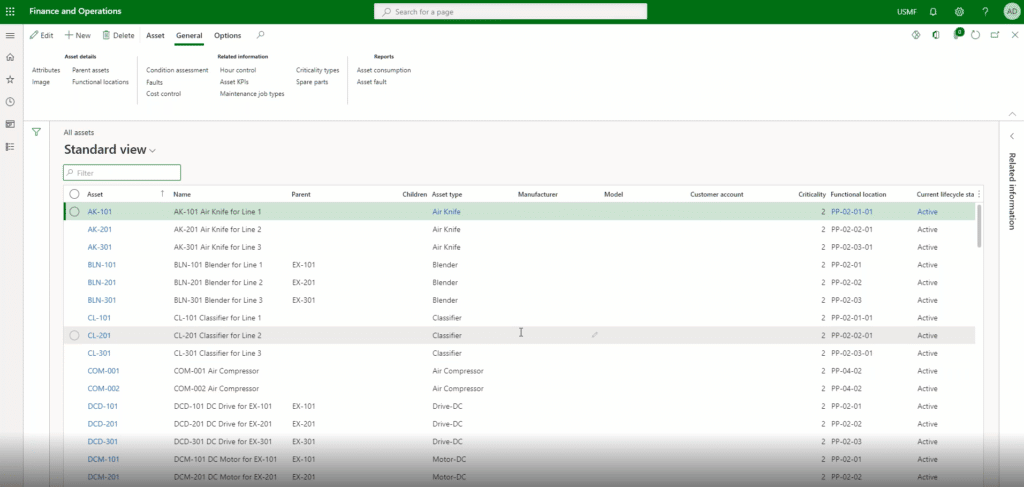

As a commodity processor, your company has a lot of different machines you use to run your business. This means you have many different types of assets that need to be tracked, and this solution lets you do that.

It also lets you manage your assets from a financial standpoint, as you can track them from the moment you buy them to when you have to replace them. You can track the cost of purchasing an asset, the cost of its maintenance, and what it will cost to depreciate and replace it. This includes operational maintenance requests, which are requirements for machines going through and doing your processing.

Finally, it also lets you manage the potential impact in production processing when using more advanced Material Requirements Planning (MRP) capabilities. Many commodity processors think keeping the processing floor busy is the best way to do business. What some don’t often consider, however, is how the demand generation for the end ingredients being produced can drive decisions in commodity purchases within the system. This is a gap that EAM can fill.

For example, if one of your key machines breaks down on the floor, it will cause a downtime event and a stoppage in production. This affects what you’re selling and the fulfillment of your contracts and orders as well. Being able to track what went wrong and how to fix it will go a long way in rectifying that situation and ensuring it doesn't happen again.

What You Should Know About the Enterprise Asset Management Basics

There are five many areas within the system that allow you to do this kind of processing:

- Asset – This is detached from the fixed asset and the resource in the production

- Functional location – Figuring out where that asset is actually located so you can quickly identify and direct workers to complete maintenance and repair events

- Maintenance requests – While it would be ideal only to have to do preventative maintenance, you’re more likely to run into break-fix scenarios with your assets. This lets you address those

- Work orders – You can apply advanced concepts to your work orders when something breaks down or is in need or maintenance

- Maintenance schedule – You can manage preventative maintenance schedules and add steps based on your company’s process

Want to learn more about what Enterprise Asset Management can do for you?

Please reach out to us! We have a team of Dynamics 365 Finance and Operations experts ready to assist you.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.