How Food Manufacturers Use Dynamics 365 ERP to Calculate Product Margins

ERP to Calculate Product Margins in Food Manufacturing: A CFO’s Guide to Accurate Costing

For financial decision-makers in food manufacturing, profitability hinges on understanding margins at a granular level. Yet for many companies, accurate costing is a constant challenge, making margin calculation anything but straightforward.

With Dynamics 365 ERP systems like Business Central, extended by YAVEON 365, or Finance and Supply Chain Management, finance leaders gain real-time visibility into costs, enabling accurate product margin analysis that drives smarter financial decisions.

The Challenges of Calculating Margins in Food Manufacturing

Food manufacturers face unique obstacles in cost tracking and margin analysis:

- Ingredient price volatility. Commodity-driven ingredients fluctuate, making standard costing models unreliable.

- Perishability. Spoilage, waste, and write-offs distort the true cost of goods sold (COGS).

- Complex production processes. Multiple recipes, yields, and byproducts complicate allocations.

- Overhead absorption. Energy, labor, and distribution costs are often not accurately attributed to specific products.

- Disconnected systems. Finance teams struggle with manual reconciliations when costing data lives across spreadsheets and legacy tools.

For a CFO, these challenges translate into delayed insights and unreliable profitability reporting.

How ERP Systems Deliver Real-Time Margin Visibility

An ERP for profitability integrates production, finance, and supply chain data into one platform. Instead of waiting for end-of-month reports, CFOs get the margin insights they need when decisions matter most. This gives you:

- Real-time product costing ERP capabilities that track actuals as they happen

- Automated allocation of labor, overhead, and raw material costs

- Margin visibility at the SKU, batch, or customer level

- Instant variance analysis to spot where margins are shrinking

Automate Costing and Margin Analysis with Dynamics 365

Microsoft Dynamics 365 food costing tools automate what many finance teams spend weeks piecing together manually. Automation reduces human error, speeds up financial closes, and empowers finance teams to shift from number crunching to strategic advising. Using a robust ERP to calculate product margins gives accurate, presentation-ready data in a fraction of the time.

With built-in automation, CFOs can:

- Calculate actual vs. standard costs without manual reconciliations

- Update costing models as ingredient prices change

- Automate variance reporting to identify margin leakage

- Produce real-time P&L by product line or plant

Turn Complex Cost Structures into Clear Margin Insights

In food manufacturing, costs extend far beyond ingredients. Dynamics 365 ERP provides CFOs with the ability to:

- Attribute packaging, freight, and distribution costs to specific SKUs

- Track yield losses or byproducts that affect true margins

- Analyze profitability by channel, region, or customer segment

These insights help finance leaders answer strategic questions: Which products are truly profitable? Where are margins slipping? Which customers or regions contribute most to the bottom line?

From Ingredients to Overhead: How ERP Tracks Every Dollar

A true product margin analysis ERP solution ensures every dollar is captured in costing, including:

- Direct costs. Ingredients, packaging, and direct labor

- Indirect costs. Utilities, equipment maintenance, and plant overhead

- Logistics costs. Freight, storage, and distribution expenses

- Waste and spoilage. Costs tied to shrinkage or write-offs

With all costs captured in one system, CFOs can calculate true margins—not estimates.

Microsoft Dynamics 365 ERP: Margin Calculation Tools

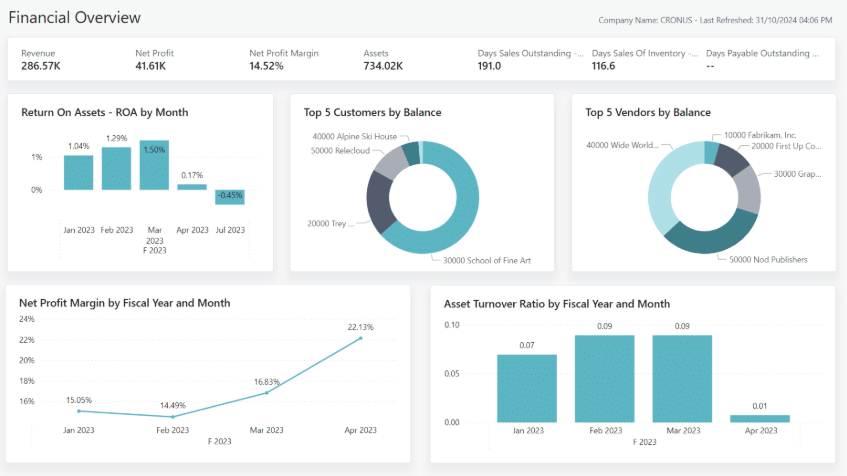

One key advantage of Microsoft Dynamics 365 Business Central/YAVEON 365 or Finance and Supply Chain Management is its ability to move beyond basic cost tracking and deliver end-to-end margin visibility. Here’s a closer look at the core tools that make accurate costing and margin analysis possible in food manufacturing:

Cost Accounting Ledger

The Cost Accounting Ledger provides a flexible framework for tracking and analyzing costs across your business. Unlike traditional accounting systems that only capture financial postings, this ledger allows you to allocate costs by department, product line, or process.

For CFOs: This gives you the ability to see how costs flow through your organization in real time, enabling you to compare actual versus budgeted performance, evaluate cost centers, and spot areas of margin erosion before month-end.

Product Costing

Dynamics 365 automates the calculation of both standard and actual product costs at the SKU level. The system factors in raw materials, yields, byproducts, and overhead allocations.

For CFOs: This provides clarity on true cost per unit and eliminates the need for manual spreadsheets. You can easily model the financial impact of ingredient price fluctuations, helping to make faster, data-driven pricing and sourcing decisions.

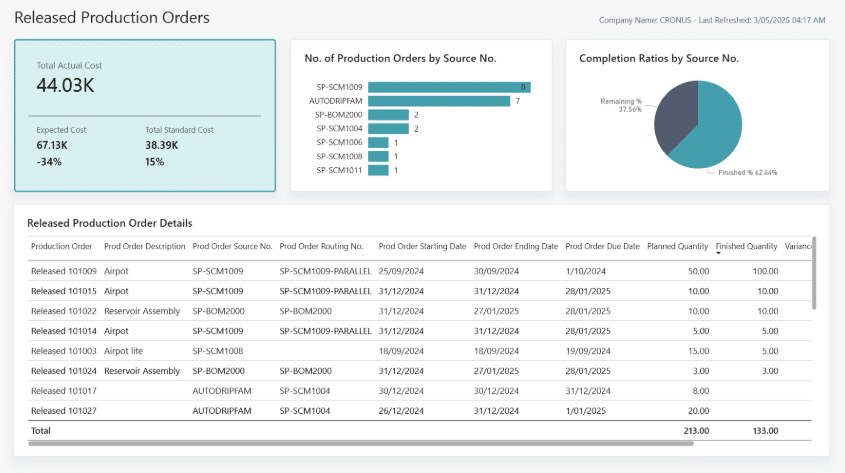

Production Order Cost Analysis

As products move through the manufacturing process, Dynamics 365 tracks costs in real time. Every material consumption, labor entry, and overhead allocation is captured and compared against expected standards.

For CFOs: This gives immediate visibility into where production efficiency is slipping. Instead of waiting until the end of the period to discover overruns, you can intervene mid-cycle to protect margins.

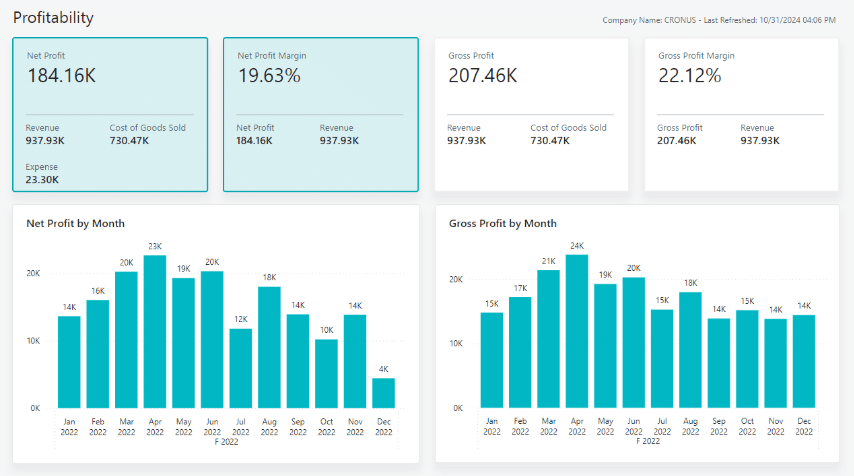

Profitability Reporting

Dynamics 365 delivers configurable reports that show profitability by product, customer, region, or channel. Reports can be drilled down to batch or lot levels, offering granular insights into which areas of the business drive profit and which underperform.

For CFOs: This empowers you to steer strategic conversations with the executive team. You can identify high-margin products worth expanding and low-margin lines that may require reengineering—or even discontinuation.

What-If Analysis

With Dynamics 365, finance leaders can run scenario planning models to simulate the impact of cost changes. For example, what happens to margins if ingredient costs rise by 10%, or if freight rates increase across a distribution channel?

For CFOs: These tools support proactive decision-making. Instead of reacting to cost increases after they hit the P&L, you can model options in advance, negotiate with suppliers, or adjust pricing strategies to maintain profitability.

Why Food Manufacturers Partner with Stoneridge Software

Implementing ERP is a significant investment—and the right partner ensures it delivers ROI. At Stoneridge Software, we specialize in Microsoft Dynamics 365 ERP for food manufacturing, helping CFOs:

- Build accurate, automated costing models

- Align ERP functionality with finance-driven decision-making

- Uncover margin insights that drive profitable growth

- Reduce waste and improve cost recovery across operations

If your team is ready to move from manual costing to margin visibility that empowers smarter decisions, we can help.

Contact our experts at Stoneridge Software today to set up your personalized D365 ERP demonstration.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.