Why Commodity Processors Should Choose Dynamics 365 As Their Manufacturing Production Planning Software

Dynamics 365 Finance and Supply Chain Management is a powerful manufacturing production planning software solution that can help you balance supply and demand while optimizing capacity.

Using this solution gives you access to powerful tools to help you navigate these, minimize downtime, and maximize efficiency, including Material Requirements Planning (MRP) and Master Planning capabilities. In this blog, we will explore demand-driven vs supply-constrained planning, resource constraints, and how Dynamics 365 Demand Planning can enhance your forecasting and decision-making abilities.

Understanding Planning in Commodity Processing

There are two primary ways to plan in an Enterprise Resource Planning (ERP) system: Demand-Driven Planning and Supply-Constrained Planning. Let’s look at both.

Demand-Driven Planning

This follows a pull-based approach where production is initiated based on incoming demand. The system then generates planned purchases, production, and transfer orders to meet this demand. It essentially follows four steps:

- Demand comes in: A client customer wants to buy something from you, and their demand comes into your system.

- Planning execution: You and your team plan how to get that product to the customer.

- Production: The product your customer wants is built, inspected, and made ready for sale.

- Product delivery: Once you have the quality and quantity of product the customer requested, you send it to them.

Supply-Constrained Planning

This method is resource-dependent, meaning production is determined by the availability of raw materials. Instead of reacting to customer demand, you produce what you can with your available supply. Essentially, the first two steps from the planning cycle above don’t happen, as you already know what materials and constraints you must work with.

Why is Manufacturing Production Planning Software Important for Commodity Processors?

For commodity processors, efficiency and precision are key to staying competitive, and production planning ensures raw materials, labor, and equipment are optimally allocated to meet demand while minimizing waste and delays. Investing in this type of software helps you avoid the risk of bottlenecks, stock shortages, and costly downtime, all of which disrupt your operations and hurt your profit margins.

Here are some key benefits for commodity processors who invest in a strong production planning software solution like Dynamics 365 Finance and Supply Chain Management:

- Improved Efficiency: Automates scheduling, reducing manual errors and optimizing resource use.

- Reduced Waste: Ensures precise material planning to minimize excess inventory and spoilage.

- Enhanced Agility: Adapts quickly to demand fluctuations, weather disruptions, or supply chain issues.

- Better Compliance: Helps track regulations and quality standards, ensuring consistent product quality.

- Cost Savings: Reduces downtime, excess labor costs, and inefficiencies that impact the bottom line.

- Data-Driven Decision Making: Provides real-time insights for better forecasting and strategic planning.

Dynamics 365 Finance and Supply Chain Management is a great solution that will help you maximize productivity and profitability.

The Role of MRP in Supply-Constrained Manufacturing

A common misconception is that MRP is unnecessary in a supply-constrained environment. However, even when raw materials are limited, MRP helps by:

- Tracking inventory levels and preventing shortages

- Optimizing procurement by forecasting future raw material needs

- Minimizing production delays by ensuring resources are used efficiently

For example, an ethanol plant that relies on a corn supply must carefully plan its purchases to avoid shutdowns. By leveraging MRP in Dynamics 365, organizations can predict supply shortages and generate planned purchase orders to maintain continuous operations. Here are some key benefits of using MRP in demand planning:

- Reduced operational downtime: Proactively managing raw materials ensures production runs without costly interruptions.

- Lower inventory carrying costs: Avoid over-purchasing or stockpiling unnecessary materials.

- Improved supplier relationships: Accurate forecasting enables better negotiation and procurement planning.

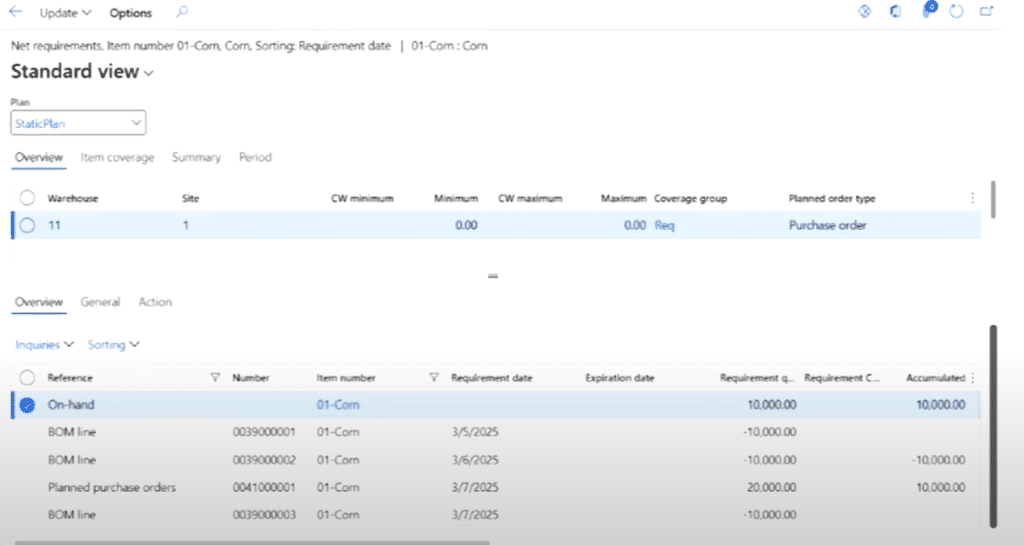

Leveraging Net Requirements with Dynamics 365

Microsoft Dynamics 365 Net Requirements provides real-time insights into supply and demand, helping manufacturers make data-driven decisions. For instance:

- It allows businesses to track raw material levels and avoid stockouts.

- It helps identify gaps in supply deliveries, reducing unplanned downtime.

- It generates purchase or production orders to ensure seamless manufacturing workflows.

These features eliminate bottlenecks caused by material shortages, enhance decision-making by improving responsiveness to changing demand, and give you greater control over procurement and logistics.

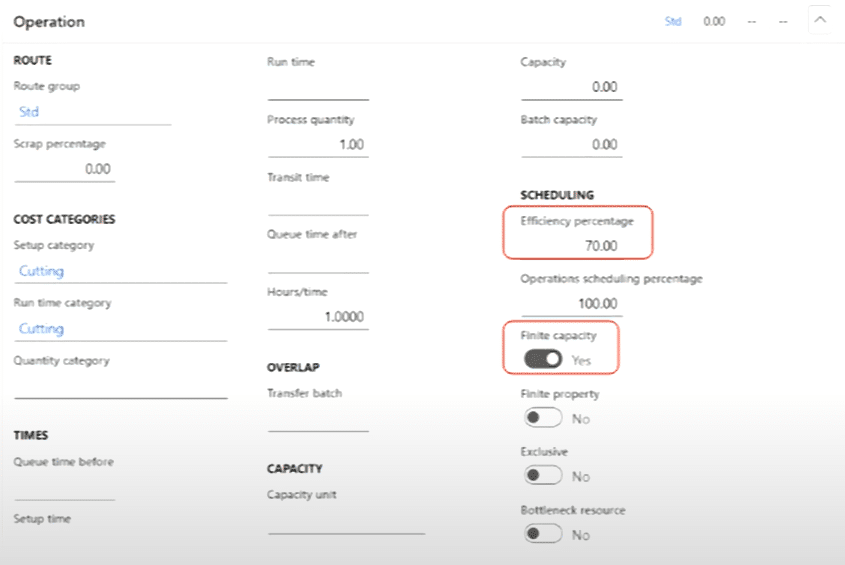

Managing Resource Constraints in Dynamics 365

Beyond raw materials, manufacturing operations face resource constraints, such as machine bottlenecks and efficiency issues. Microsoft Dynamics 365 allows businesses to define resource limitations, including:

- Finite capacity settings to prevent overloading machines

- Efficiency percentages to account for aging equipment

- Operation runtimes to optimize scheduling and production throughput

These tools help manufacturers anticipate production delays and adjust their schedules to maximize efficiency. Using Dynamics 365 Finance and Supply Chain Management to address this comes with several benefits:

- Higher machine utilization rates: Maximizing throughput while reducing wear and tear.

- Optimized workforce allocation: This ensures employees are effectively scheduled to minimize idle time.

- Improved production planning: Reduces bottlenecks and optimizes operational flow.

Forecasting with Dynamics 365 Demand Planning

Forecasting is essential for long-term manufacturing success. Microsoft Dynamics 365 offers Demand Planning tools, which use historical data and external factors (e.g., weather, market trends) to generate accurate forecasts. Two types of MRP can be calculated in your ERP system:

- Supply Forecast: Pulls historical data to predict what your supply will look like. This helps you plan your production processes and assess the volume of product you can put out.

- Demand Forecast: This also pulls data from your system to predict the demand of certain products at certain times. For example, if you have a product that sells more in the summer, the system will notice that and add it to your forecast so your team can prepare that item.

MRP also treats each supply forecast as “Supply” and the demand forecast as “Demand” during its calculation.

Enter the Dynamics 365 Demand Planner App

With the Dynamics 365 Demand Planner app, you can put your historical sales and inventory levels and additional context into the tool to help you develop forecasts. You can also tailor these forecasts to span years, helping you plan your purchasing and production decisions well into the future.

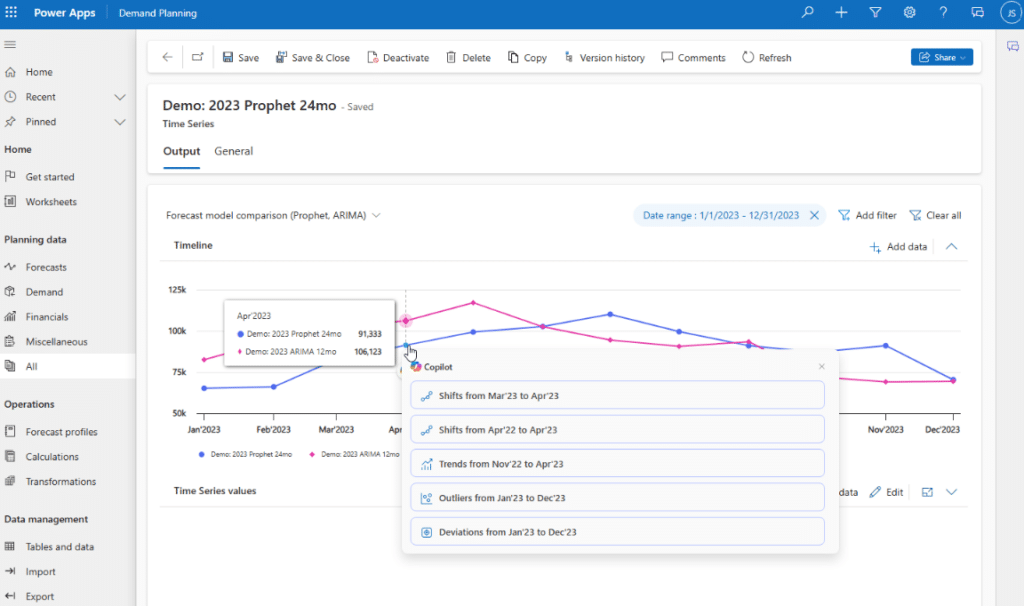

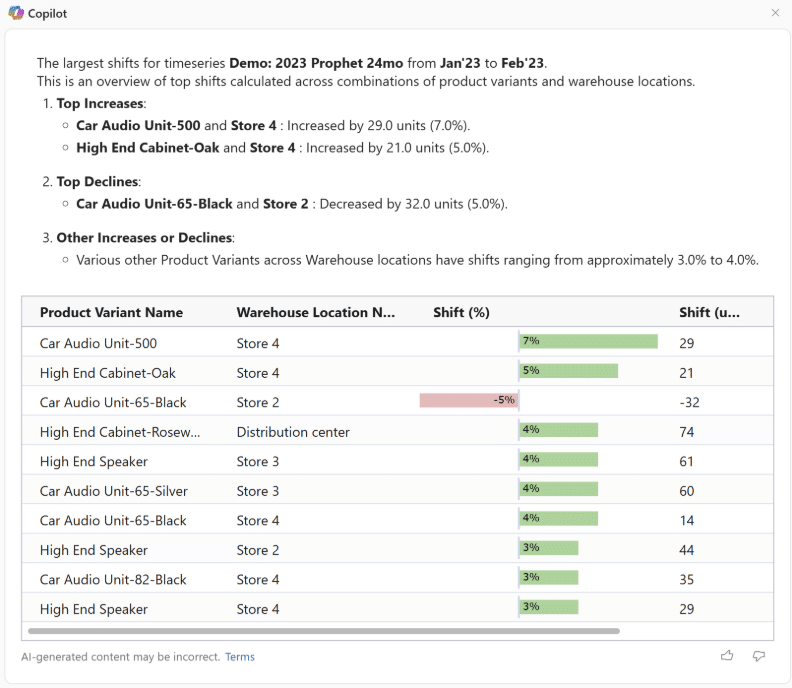

AI-Driven Assistance with Microsoft Copilot

One of the tools now integrated into the Demand Planner app is Microsoft Copilot, which contains AI capabilities to help you with various planning and production scenarios, including:

- Analyze past sales and inventory trends

- Incorporate external data for enhanced forecasting accuracy

- Use AI-driven insights to improve demand and supply predictions

Here is a good example of demand planning: A grain milling company can leverage demand forecasts to ensure packaging materials are always available while accommodating fluctuating supply constraints for raw grains.

Forecasting with Dynamics 365 Finance and Supply Chain Management is crucial for several reasons:

- Better financial planning: Predictive insights lead to more informed budgeting and investment decisions.

- Reduced excess inventory: Aligning supply with actual demand helps avoid waste and overstocking.

- Improved customer satisfaction: Ensures on-time fulfillment by proactively managing supply chain risks.

Next Steps: Implement Dynamics 365 Finance and Supply Chain Management to Enhance Demand Planning

Finance and Supply Chain Management offers robust demand planning capabilities to help manufacturers optimize their product development processes from start to finish. In terms of where to go from here, we recommend following these four steps:

- Take advantage of the Finance and Supply Chain Management built-in planning engine where it makes sense.

- Ensure your system is set up to consider bottleneck resources.

- Consider using the Demand Planning functionality for more precise extended planning.

- Contact a Microsoft Partner who can help you get the most out of this system

If your organization wants to optimize manufacturing planning and supply chain efficiency, now is the time to leverage Microsoft Dynamics 365. Implementing MRP, Net Requirements, and AI-driven Demand Planning can help your business avoid disruptions and enhance productivity.

Talk to the Stoneridge Experts Today to Improve Your Planning Processes

The Stoneridge team has plenty of experience helping Ag manufacturers set up and optimize Dynamics 365 Finance and Supply Chain Management. Whether you are new to Dynamics 365 or want to improve your planning processes, our experts can help you.

Reach out today to learn more.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.