AI in Manufacturing: Transform Your Operations with the Connected Cloud

Taking advantage of AI in manufacturing can help your organization capitalize on evolving opportunities and address new challenges with confidence.

As technological innovations and customer expectations evolve, the manufacturing industry is constantly changing. To continue thriving, manufacturers need to revisit, and potentially rethink, their strategies and operations. A very effective way to do that is to harness the combined power of AI and the connected cloud.

Maximize Cloud Technology Investments with AI in Manufacturing

The cloud has changed over the past 10 years, but it can still help you positively change your operations when combined with AI. In this blog, we will explore emerging trends and technologies shaping the future of manufacturing. Additionally, we will showcase how these innovations can optimize your operations and drive growth for manufacturing companies.

How the Cloud Evolution Has Changed Manufacturing

A lot of things have changed over the past 10 years in the cloud computing landscape. If you haven’t evaluated your business systems recently, you might be missing out on some of the benefits and opportunities that the cloud offers. Here are some of the key changes that have happened in the cloud in the last decade:

Security

When you first started looking at the cloud, you were probably worried about security and reliability. Today, the cloud is far more secure than anything that you can do on-premise. Cloud providers invest heavily in several important security measures and compliance standards. This includes encryption, backup, and disaster recovery options that are hard to match with on-premise solutions. You can now trust the cloud to protect your data and your business.

Accessibility

More recently, there has been an increasing demand for accessing systems on multiple different devices. With the pandemic, more and more people work from home. You also have the opportunity to enable people to work in the field on their mobile devices or tablets. The cloud makes this possible by allowing you to access your data and applications from anywhere, anytime, and on any device.

Flexibility

Software as a Service (SaaS) is now very common and it allows you to plug in a solution that fits your business easily. You can turn something on or off as you need it, and you only pay for what you use. This flexibility gives you the ability to scale up or down as your business needs change. You can also customize and configure your cloud solutions to suit your specific requirements and preferences.

Low-code or No-code Platforms

Low-code or no-code platforms are an innovative way to build solutions that connect to your core system with fewer resources than before. Whether you use existing software or create your own, you can integrate it with your system faster and easier.

Integration

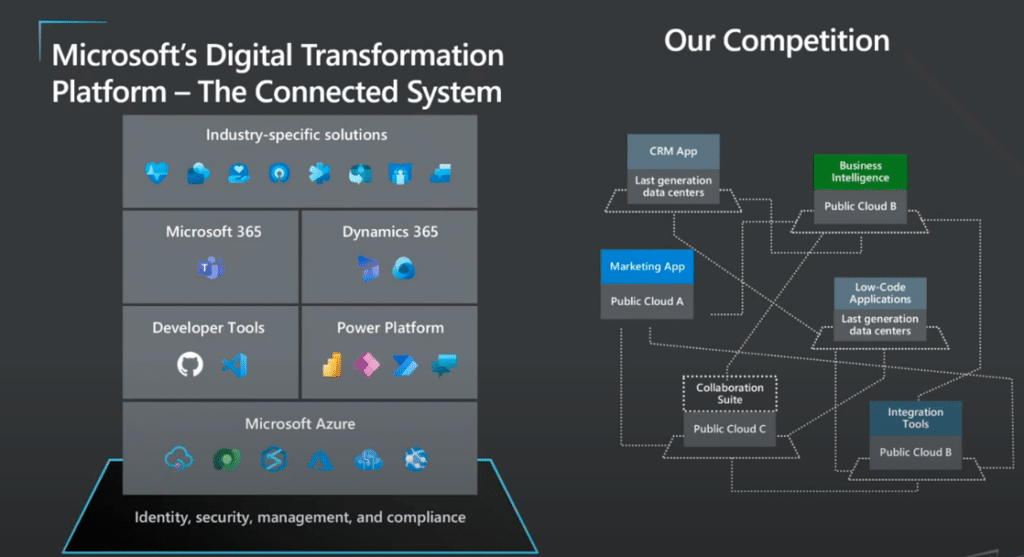

Today’s connected cloud environment makes system integration much easier, and Microsoft offers a powerful integrated platform. With the Dataverse model that supports the Microsoft Dynamics environment, you can create smooth and integrated connections.

Visualization

Another benefit of the connected cloud environment is the ease of creating business intelligence reports with Power BI. Power BI is a tool that lets you connect to various data sources so you can create visualizations to help you make more informed decisions. You can also share and collaborate on your reports with your team and stakeholders easily.

Future Technology Trends with AI in Manufacturing and the Connected Cloud

The connected cloud computing landscape is constantly changing and continuously offering new benefits and opportunities for manufacturers. Below are some of the crucial areas that are advancing:

Artificial intelligence

AI is transforming the way we work and live and can help you create efficiency, save costs, and improve customer service. It is a key focus of what Microsoft is bringing to the table offering various tools and platforms that you can leverage to enhance your solutions and gain insights.

Robotics

Robotics is another area that is going to play a big role in the manufacturing industry. You can use humanoid-type robots to automate tasks and processes on your manufacturing floor and integrate them with your centralized system. This helps you improve visibility, productivity, and quality.

Internet of Things

IoT is about connected devices that can communicate with each other and with the cloud. You can use IoT to collect and analyze data from various sources and take action on it. You can optimize your energy consumption, prevent failures, and enhance your customer experience with IoT.

Microsoft Fabric

Microsoft Fabric is a platform that brings all of your disparate databases into one BI platform. You can access and analyze data from various sources, both in the cloud and on-premise and get insights that can help you improve your business performance and outcomes. As mentioned earlier, you can also use Power BI to create visualizations and dashboards to share with your team and stakeholders.

Maximizing the Benefits of Technology Evolution with AI in Manufacturing

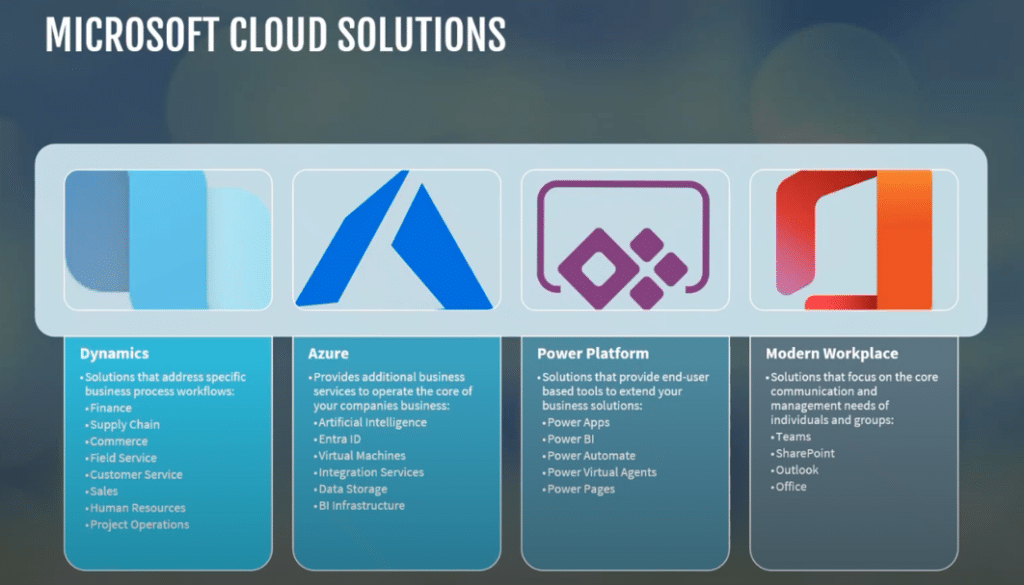

By moving to the cloud, you can access the best of Microsoft’s cloud solutions, such as Dynamics 365, Azure, Power Platform, and Modern Workplace. These solutions can help you optimize your processes, integrate your systems easily, enhance your customer experience, and discover new possibilities for growth.

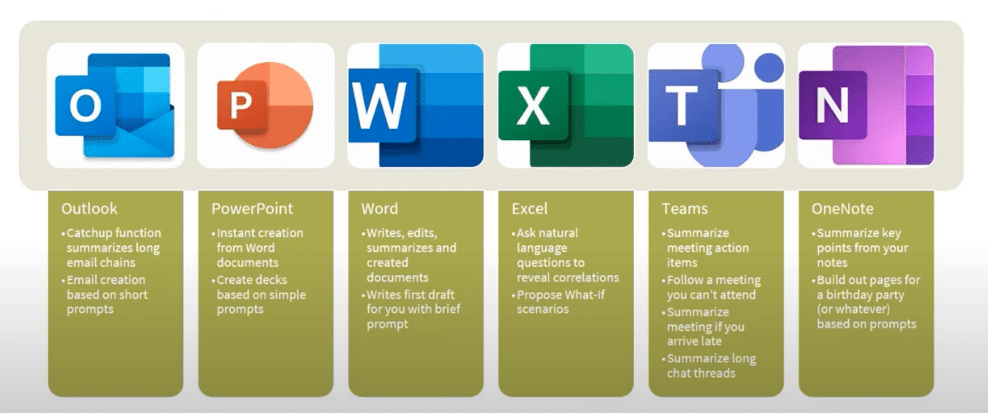

Making these solutions even better is Microsoft Copilot, which lets you use AI to automate and streamline processes in the apps you use every day:

Here are some of the top notable benefits manufacturers will see once they decide to move to the connected cloud:

Easy integrations

Integrate your data and workflows across different cloud services, without having to worry about compatibility, security, or performance issues. For example, you can use D365 to manage your core business functions and then connect it with Azure, Power Platform, and Modern Workplace. This extends its capabilities with custom applications, data analytics, automation, and collaboration tools.

Best practices

You will benefit from the proven and tested business processes that Microsoft has developed over the years. For example, you can use Dynamics 365 to implement features and capabilities such as three-way matching, manufacturing execution systems, or inventory management without having to create your systems from scratch. These processes are embedded into Microsoft's cloud-based technologies.

User experience

Improve the user experience of your employees and customers by providing them with the right tools for the right tasks. You can also personalize solutions to their needs and preferences. For example, you can use Dynamics 365 to provide your salespeople with a dedicated CRM system, instead of having them use an accounting system for lead and opportunity management. Team members can also use Power Platform to create custom applications without requiring any coding skills.

Innovation

Harness the power of the connected cloud to explore new possibilities for your business and to stay ahead of the changing market demands and customer expectations. For example, you can use Azure to access a wide range of cloud services, such as logic apps, artificial intelligence, or blockchain. These can help you solve complex business problems and create new value propositions. From there you can also use Power BI to analyze and visualize your data, and to gain insights that can drive better decisions and action.

Addressing Industry Challenges with Cloud Technology

The manufacturing industry is complex and dynamic and faces many challenges in today’s world. Some of the most pressing issues we see from our clients are labor shortages, supply chain disruptions, macroeconomic uncertainties, operational inefficiencies, and changing distribution models. Because of this, businesses like yours are continuously looking for ways to overcome these obstacles. Adopting a connected system that leverages cloud technology and data analytics is a viable solution to tackle many of these challenges.

AI and automation features in a cloud-connected system can help manufacturers:

- Improve their labor productivity

- Enhance their supply chain visibility

- Adapt to the changing global environment

- Streamline their operations

- Expand their market reach

- Create a competitive edge.

AI in Manufacturing Technologies Benefits Businesses

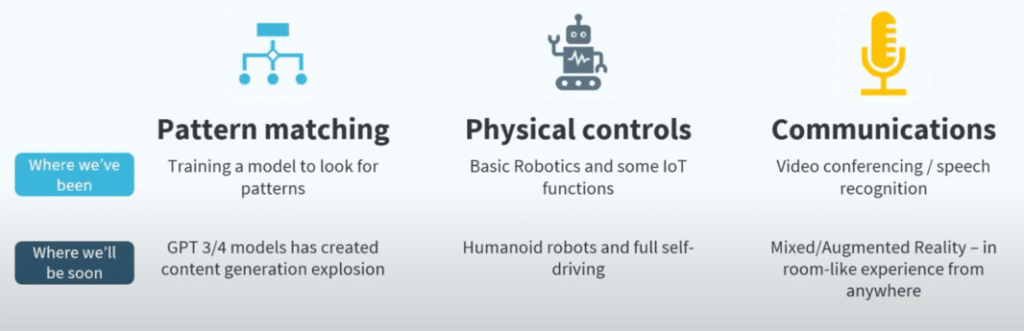

AI, in general terms, can be divided into three main categories today: pattern matching, physical controls, and communication.

However, there are specific ways manufacturers are leveraging many of these AI technologies to address their business challenges and achieve their goals. Some of the common use cases of AI in manufacturing are:

Computer vision

You can use AI to analyze images and videos to detect quality issues, defects, or anomalies in the products or processes. For example, you can use computer vision to inspect a product issue and identify any errors or deviations from the standard.

Large language models

AI can generate natural language texts or speech based on the input or context. For example, you can use a large language model to create a blog post, a product description, or a customer review.

Machine learning

Strong AI systems can learn from data and make predictions or recommendations based on patterns or trends. For example, you can use machine learning to forecast the demand for their products or to predict the likelihood of late payments from their customers.

By harnessing the transformative power of AI and the connected cloud, manufacturers can unlock unprecedented efficiency, enhance customer satisfaction, and drive sustainable growth.

Interested in Learning More About How AI in Manufacturing Can Help Your Business?

If you are ready to transform your manufacturing operations through the use of AI and the connected cloud, contact Stoneridge Software today. Let's unlock the full potential of these innovations together and propel your business into the future.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.