AI Forecasting and Production Tools for F&B Manufacturers

AI Forecasting and Production Tools for Food & Beverage Manufacturers

As food and beverage manufacturers face rising costs, tighter regulations, and ever-changing consumer preferences, the need for intelligent, data-driven decision-making has never been greater. Fortunately, the artificial intelligence (AI) embedded within Microsoft Dynamics 365 ERP transforms how the modern F&B sector operates.

By leveraging predictive analytics, machine learning, and real-time automation, AI-powered ERP platforms enable food and beverage companies to become more agile, efficient, and responsive.

The Case for Predictive Analytics in F&B ERP

Forecasting has always been a cornerstone of production planning in the food industry. However, traditional models often fall short. Static forecasts struggle with volatile factors like seasonal demand, raw material availability, weather patterns, and evolving consumer behavior.

Microsoft Dynamics 365 ERP integrates AI-driven predictive analytics to close this gap. First, the system generates more accurate and dynamic demand forecasts by analyzing:

- Historical sales

- Market trends

- Social signals

- External data (such as inflation or supply chain disruption risks)

But these AI-enhanced insights go far beyond spreadsheets. Instead of relying solely on averages or past patterns,

Dynamics 365 uses machine learning to recognize complex data relationships, uncovering patterns that human planners might overlook. This level of foresight allows F&B businesses to:

- Anticipate demand spikes

- Align procurement strategies

- Reduce stockouts

- Prevent overproduction

According to Microsoft industry research, companies implementing AI-enabled forecasting tools report up to a 30% improvement in forecast accuracy—a critical advantage in minimizing inventory costs while maximizing service levels.

Improving Line Scheduling With AI Recommendations

Production scheduling in food manufacturing is notoriously complex. Factors such as product perishability, allergen segregation, cleaning cycles, and fluctuating ingredient availability create a dynamic environment with little room for error.

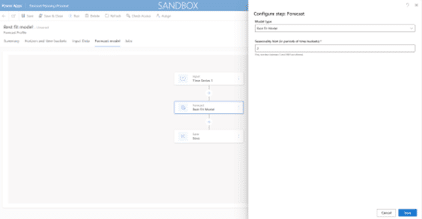

AI capabilities in Dynamics 365 help solve these challenges by recommending optimal production sequences, based on real-time data from inventory, customer orders, machine availability, and labor capacity. The system continuously adjusts schedules as new inputs arrive, reducing downtime and improving on-time delivery.

Examples of How AI Can Revolutionize Line Scheduling

Problem: An unexpected raw material delay affects a high-demand SKU

Solution: Dynamics 365’s scheduling AI can automatically suggest rescheduling that product’s batch and prioritize another that maximizes yield or minimizes setup time.

Problem: A seemingly random series of breakdowns

Solution: AI-driven insights can detect bottlenecks and propose preventive measures, such as running regular maintenance or shifting workloads across production lines. This proactive approach boosts operational efficiency and keeps production agile.

How Machine Learning Enhances Demand Planning

Demand planning in food manufacturing impacts procurement, storage, logistics, and profitability. Machine learning (ML) in Dynamics 365 takes demand planning to the next level by learning from both structured and unstructured data over time.

ML models within the ERP analyze variables such as:

- Past sales patterns

- Promotional activity

- Economic indicators

- External supply chain risks

Unlike static rules-based systems, these models improve with every cycle, delivering more precise planning over time. For example, a beverage company might find that weather fluctuations and event calendars significantly impact specific product lines. Machine learning identifies and incorporates these correlations into future forecasts, enabling the business to adjust raw material orders and warehouse staffing proactively.

Moreover, Dynamics 365’s AI capabilities can simulate “what-if” scenarios to help planners assess how changes, like new product launches or pricing shifts, might affect demand. These simulations help businesses reduce guesswork, enhance strategic agility, and effectively meet customer needs.

Balancing Automation and Operator Control in ERP

As powerful as AI is, automation in food production still requires human oversight. Food safety, quality assurance, and customer satisfaction depend on human judgment and accountability. Dynamics 365 offers tools that blend automation with operator control, enabling manufacturers to stay efficient while ensuring quality and compliance.

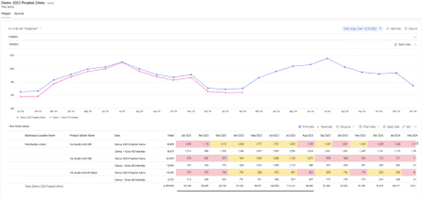

Users can set business-specific rules and thresholds within the system, for instance, limiting AI-driven order adjustments to specific SKUs or requiring managerial approval for large schedule changes. Operators can monitor AI suggestions through visual dashboards, adjust forecasts manually, or override recommendations when unique conditions arise.

This balance allows food manufacturers to retain human expertise while leveraging AI for repetitive or data-heavy tasks. Employees spend less time number-crunching and more time making strategic decisions.

Microsoft’s AI features also support collaboration via integration with Microsoft Teams, Power BI, and SharePoint. This integrated approach helps stakeholders across departments share data, comment on forecasts, and align on operational plans in real time. It fosters transparency and enhances cross-functional decision-making.

Let Stoneridge Implement Your Comprehensive F&B ERP System

AI-driven ERP systems transform data into action, helping you reduce waste, respond faster to market changes, and deliver products with greater consistency and quality. Stoneridge Software helps F&B companies create and install D365 ERP platforms, and we stay with you throughout the implementation of your modern system. Talk to the experts at Stoneridge Software today to discuss your options.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.