On the Job with Dynamics 365 – Manufacturing Material Handlers

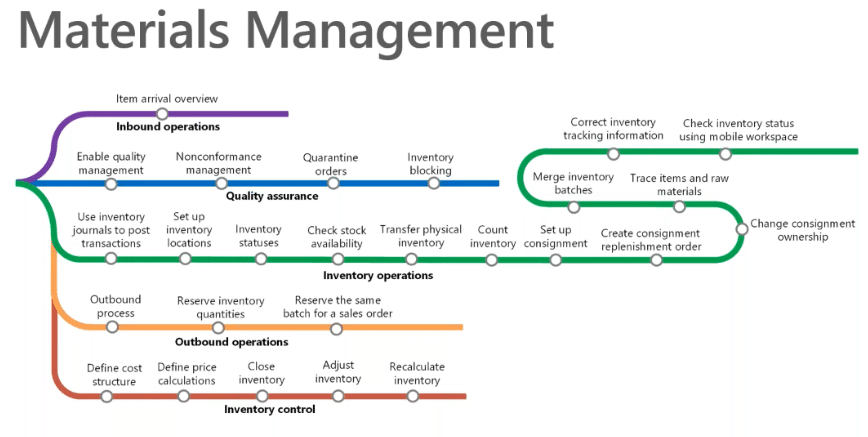

A manufacturing material handler is responsible for executing the manufacturing process including pulling orders, delivering materials and supplies, and staging the finished product. Materials management is a complex process and includes a variety of different stages and steps from beginning to completion.

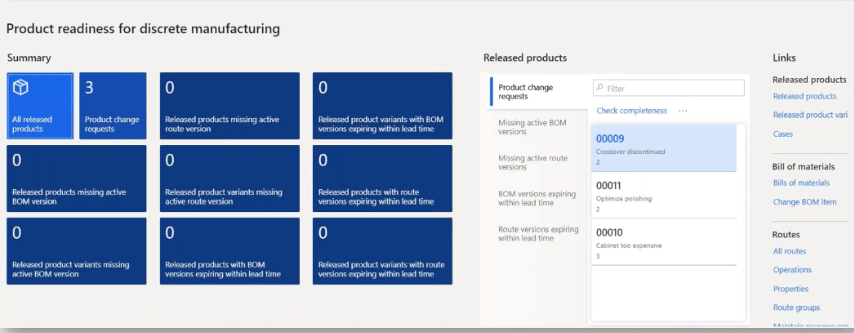

There are many benefits when material handlers are kept up to date on released new products and knowing what new products are coming. Prior to the release of new BOMs and work orders for these new items, material handler management should review to ensure the items have the correct location, stocking policy, boxing policy, correct pick and put workflows assigned, special handling instructions, etc. By involving material handlers, you reduce the probability of errors or missing information needed on the shop floor.

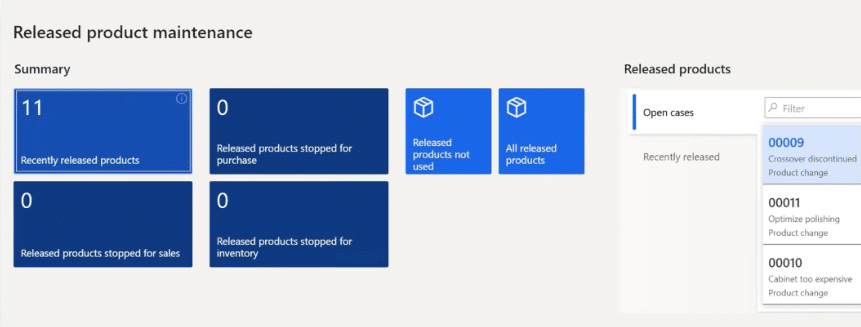

These details can be accessed within the released product maintenance window in Dynamics 365 Finance and Supply Chain under “recently released products”.

This window also offers insights to released products stopped for inventory. If an item was stopped for purchasing, that means purchase orders are no longer being created for those items. However, your material handlers need to be aware of what to do with purchased items coming onto the dock that was included in purchase orders prior to those items being stopped for inventory. At this point, the decision needs to be made to either continue using those items.

The management of new items, as well as the manufacturing associated with those items, is important part of material handling. Sometimes a production item is released but doesn’t include a Bill of Materials. When the production order is created, the material handlers won’t have the full information needed in order to start production. When material handlers have access to view upcoming products that will be released for manufacturing, they can quickly identify any gaps in information required to complete the run before it hits the floor. They become active participants in the data chain of product lifecycle management instead of the recipients of incomplete or inaccurate information. ms until they are no longer in inventory, or scrap the items.

Hazardous Materials

Dynamics 365 Finance and Supply Chain provides a way to compile data on hazardous materials and manage those items. Within the area of product compliance there are lists of items that can’t be distributed in certain areas. This may include items that are limited in specific countries, states, or regions depending on embargos or laws. This helps to avoid inadvertently shipping regulated items to those geographies. Additionally, this area of D365 is where MSDS are stored, along with warranty compliance information.

Material handlers need access to this data for each hazardous product. Information stored in D365 can include: storage, transportation, inventory management, safety sheets for each item, and packing and labeling instructions.

Power BI Reporting Options

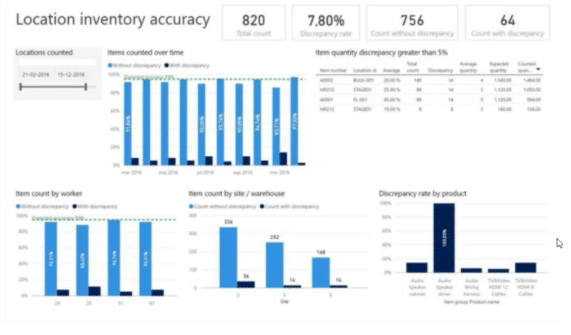

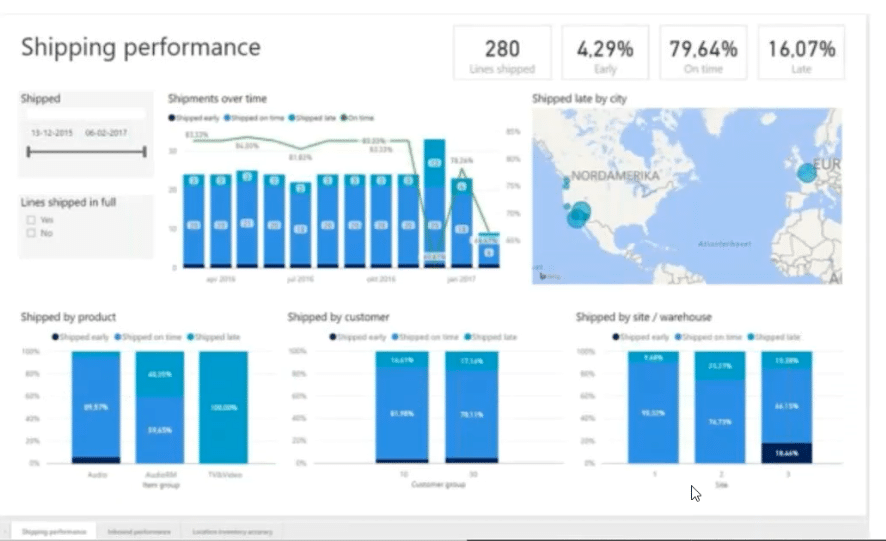

Statistics, data analysis, high level views into inventory, costing, warehousing, and more are all a part of Power BI reports that are included with Dynamics 365.

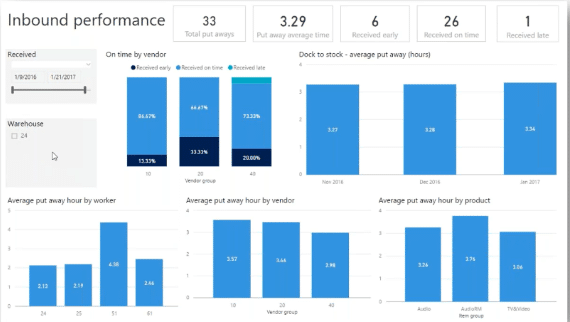

Inbound performance gives you a breakdown of what you’ve received, warehouse information, average put away hours, what are you putting away from vendors, by product, and more. New items included in this dashboard include vendor specific details and data on items received early or late.

Shipping performance and inventory accuracy are also Power BI dashboards you can start using immediately.

These are just a few examples of the capabilities of Power BI Reports.

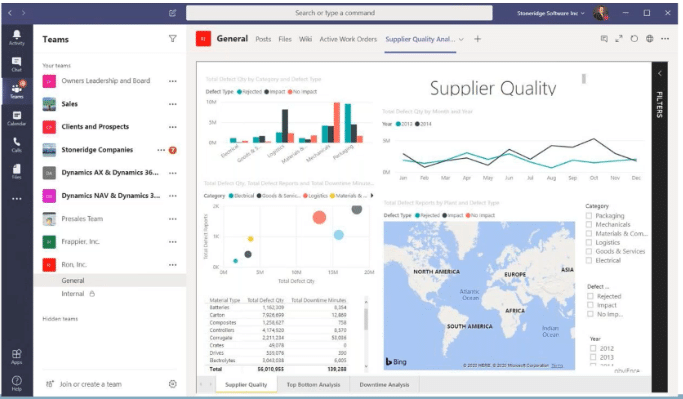

Integration with Teams

One of the top benefits of using Dynamics 365 is the seamless integration across the entire Microsoft stack. Not only are you able to import and export data to Word or Excel documents, the system also integrates with Teams. Through the native integration, information and Power BI dashboards can be accessed directly in Teams, allowing you to share it with any member of your team, even if they aren’t a Dynamics user.

Picking Workbench

Within Dynamics, you can choose how you’d like orders picked from the finished goods warehouse. Selections can be made based on different criteria including: priority, customer group, payment method, order quantity, mode of delivery, warehouse location, and more. This allows for your material handlers to become more efficient when planning and communicating picks and order fulfillment.

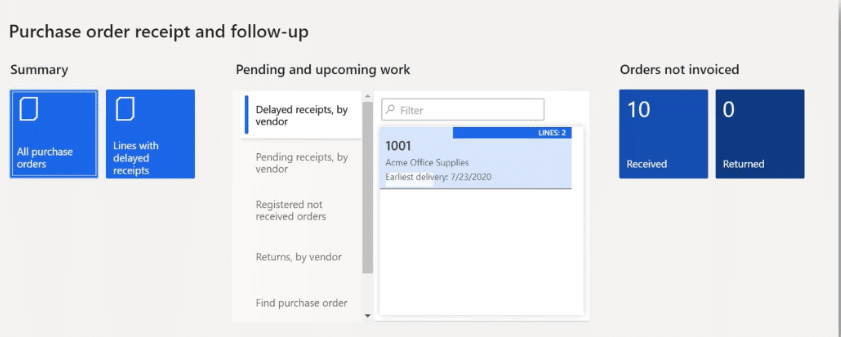

Inbound Purchase Orders

Within the dashboard view for inbound purchase orders, material handlers can view pending receipts by vendor, delayed receipts, returns by vendors, and registered by not received orders. Having visibility into work that is anticipated allows team members to stock up or down depending on pending orders.

Completing Work Using Dynamics 365

There are two different ways for material handlers to complete putaways and PO receivings within the system – basic or advanced.

Putaways

Basic:

- Transfer journal manually keyed into Dynamics

- Often requires a material handler to write down the from/to location and quantity of the items being moved

- Timing issues due to delayed data entry

- Data inaccuracy due to manual key entry

Advanced:

- Directed putaway option. Robust to define location directives for advanced putaway logic. Executed via mobile device

- Mobile device inventory movement option. Scan from location, item, LP (if required), to location, and enter quantity

- Timing is immediate

- More accurate due to scanning

Purchase Order Receiving

Basic:

- Line Registration

- Post Product Receipt

- Arrival Overview/ Item Arrival Journal

- Quality Optional

- Manual Putaway

- No Mobile Device

- No Label Printing

Advanced:

- Receive Using Mobile Device

- Label Printing Option

- Directed Putaway

- Quality Optional

- ASN/LPN Receiving Option

- Load Planning Workbench to Plan Inbound Loads

- Dock Management Appointment Scheduling

- Crossdocking Options

As you can see from both lists, the main difference in action is the mobile option. Using a mobile device to complete work makes the process faster, more accurate, and eliminates manual processes. To be successful, manufacturing operations should take advantage of the advanced functionality within the system to become more efficient.

Learn more about this process and the difference between basic and manual in this video:

Floor Management

It’s becoming evident that the days of picking inventory and staging it for production a couple days in advance are dwindling. Today’s manufacturing facilities need to drive velocity through the shop floor and reduce lead times. This means that the old way of staging inventory has typically become a bottleneck for inventory, time, and floor space. Modern manufacturers understand that inventory needs to get to the worker in a just-in-time environment. Dynamics 365 Floor Management capabilities give material handlers in formation on what’s happening on the floor and what will be in production. This ensures inventory is where it needs to be and when, just in time.

Advanced Warehousing Functionality

Advanced warehousing allows you to manage all of the areas listed below:

- Mobile device

- Wave processing

- Load planning

- Reservation hierarchy

- Inventory status

- License plates

- Flexible work creation

- Manual packing

- Containerization

- Cycle counting

- Transportation management

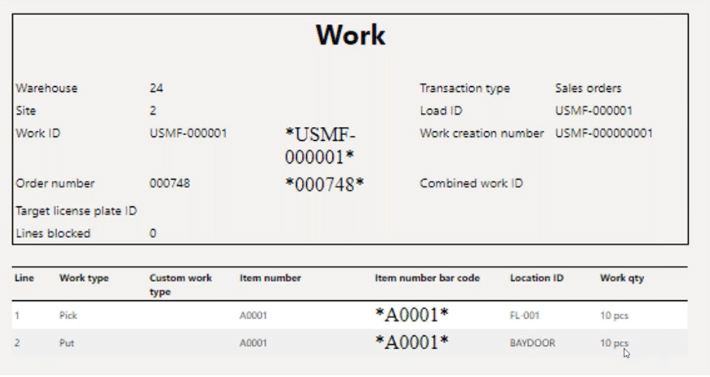

Work labels generated from the system provide all necessary information for material handlers to understand orders, quantities, locations of picks and puts, and warehouse details.

Cross docking functionality allows you to skip over inventory and take a received item directly to it’s final location.

Hear more about advanced warehousing in this video:

Material handlers are vital to the success of your manufacturing operation. To learn more about how Dynamics 365 can help them complete their job, or to learn how D365 can help your manufacturing operation as a whole, reach out to the experts at Stoneridge Software.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.