On the Job with Dynamics 365 – Manufacturing Shipping and Receiving Department

Shipping clerks at manufacturing companies are responsible for a wide range of activities from managing shipping and receiving records to organizing and transferring goods from one location to another, monitoring company packages, ensuring proper packing techniques, updating inventory reports, and more. When your shipping department uses Dynamics 365 Finance and Supply Chain Management, you can manage all aspects of the day-to-day job more efficiently and effectively.

Sales Order Processing and Inquiry Data in D365

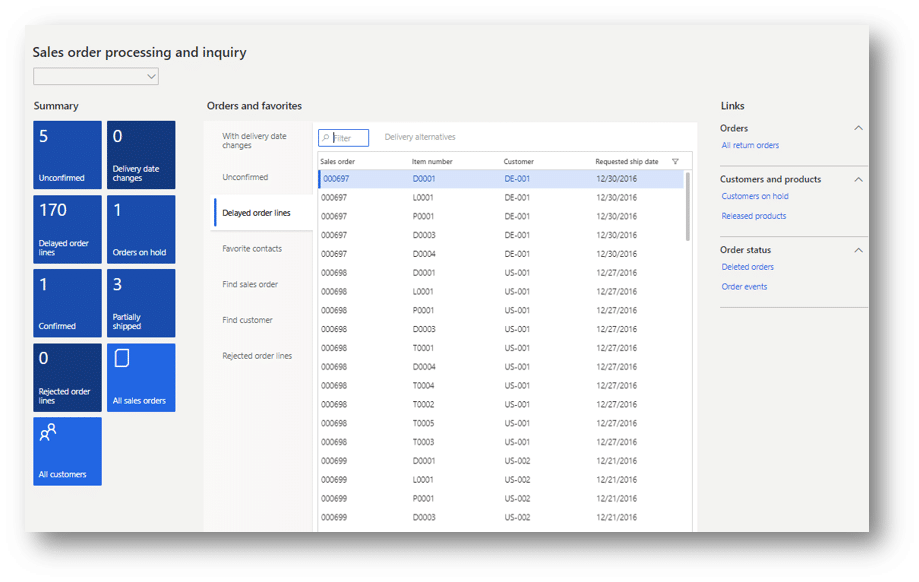

Using the Sales Workspace, shipping clerks can personalize their view to include information important to them. As you can see in the example below, tiles highlight the number of orders in progress, confirmed, on hold, delayed, partially shipped, late, and more. This helps the shipping department immediately prioritize orders and understand the overall status of the department in a single glance.

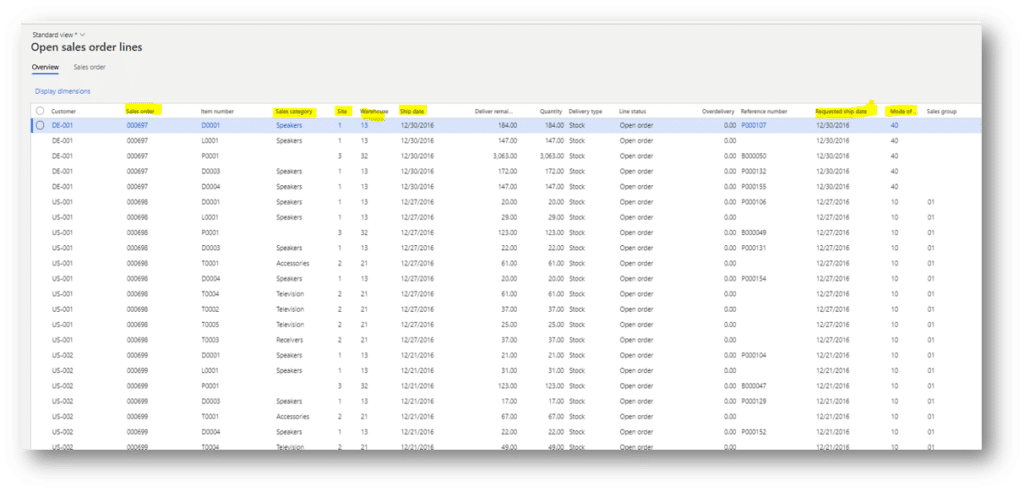

Each tile leads to more detailed information that can be sorted and prioritized. This allows the warehouse to strategize the fulfillment of orders by any criteria they determine. For example, you could sort all open sales orders by the item category, such as speakers, to generate a list of all speaker orders that need fulfillment. This enables your team to pick all like-items at the same time.

Other sorting columns include the sales order number, site, warehouse, ship date, requested ship date, and mode of delivery.

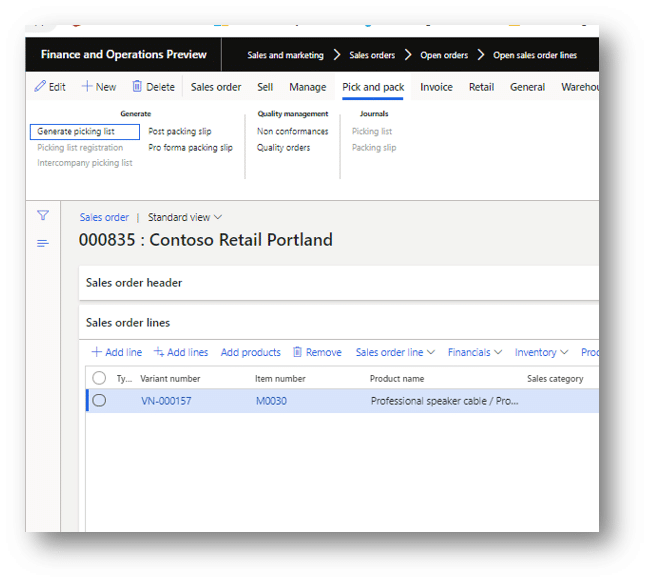

Generating a picking list is as easy as selecting those items and clicking “generate picking list”.

Backorder Management in D365

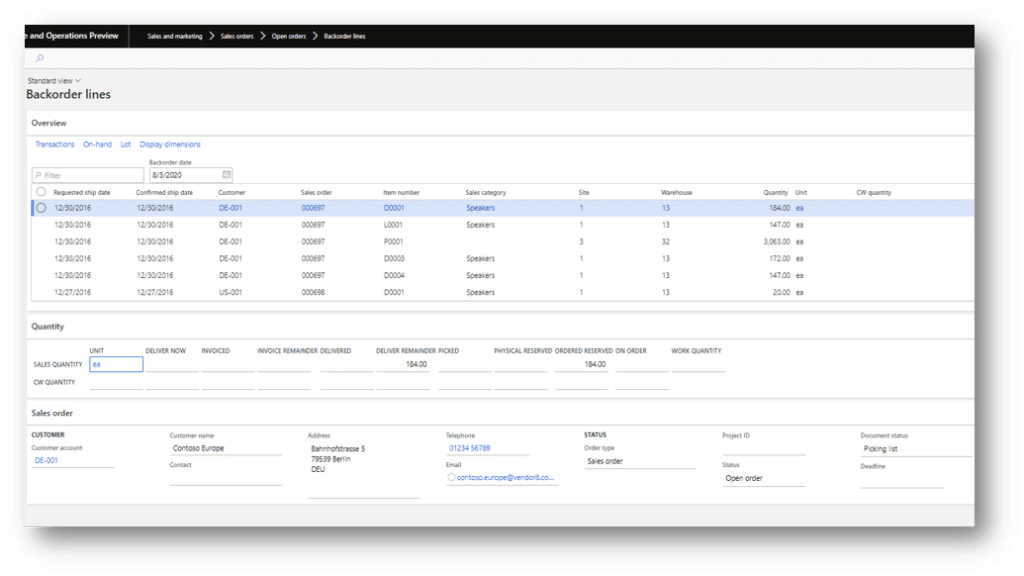

Managing and expediting backorders is critical to any manufacturing business. Within Dynamics 365 you can access a full list of backorders to speed up fulfillment, understand how much of the order has been completed, what has been invoiced, what is currently in progress, etc.

Contact information for the customer is available on the backorder log so the customer can be directly contacted regarding delays in shipments and resolution of issues as they arise.

Picklist Generation and Workbench in D365

Once a picklist has been generated, you can set up your workbench to specify the number of orders you’d like to assign to a material handler for a specific shift. This keeps your daily tasks for each handler realistic and helps you to understand how much will be completed in each shift. These picklist workbenches can be set by number of orders or lines, priority orders, payment method, and more.

This capability allows you to pick the orders first that are your top priority and gives you a more detailed way to get materials out of the warehouse and sent to your customers.

The workbench generates a picking session, also called a consolidated picking list, specific to each handler and shared directly to their mobile device. Each list can also be optimized for routes through the warehouse or factory to speed the picking process.

Sales Order Picking in D365

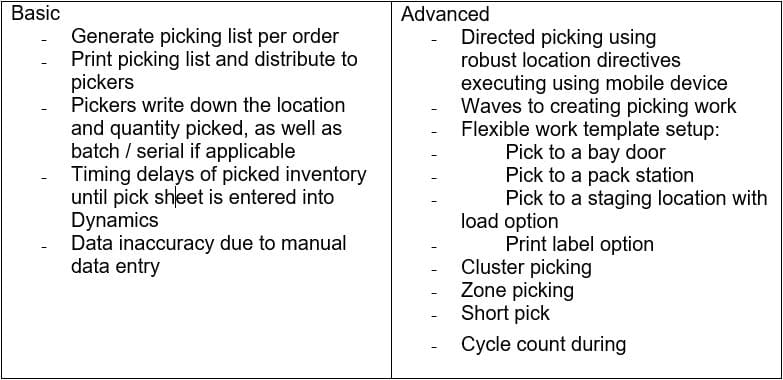

There are basic and advanced capabilities around sales order picking. Learn more about these features in the video below.

Shipping

Once the items are picked, you move into the shipping screen in Dynamics 365 where order status is updated for tracking purposes.

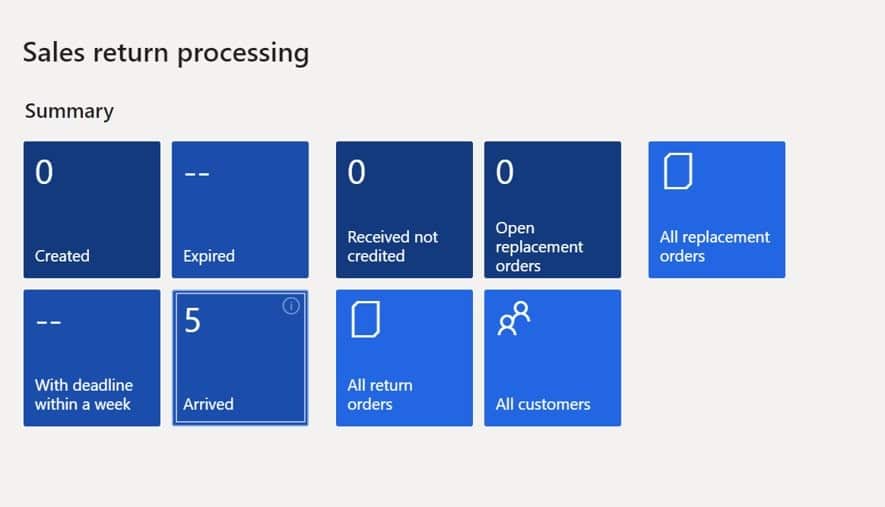

Processing Returns

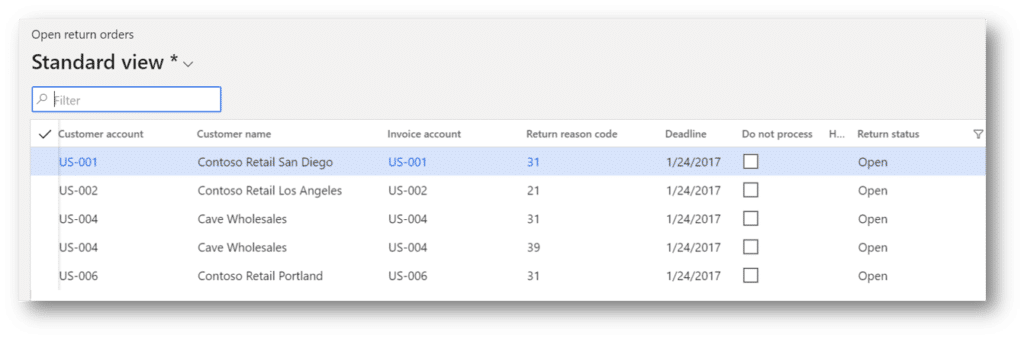

Returns are a part of any operation and with Dynamics 365 the receiving department can easily manage the return process. The Sales Return Workspace offers a quick glance at the number of returns that have arrived, deadlines, replacement order data, and more.

Drilling down into these tiles, users will find details on those returns. Reason codes, deadlines, and return status can be updated as the team completes each order. This offers an easy way to complete the return process with a high degree of visibility and accuracy.

Distributed Order Management for Commerce

Distributed Order Management allows you to optimize order fulfilment across a complex network. This functionality gives users a global view of inventory across the entire organization, including brick and mortar stores and warehouses, and allows users to more intelligently manage orders to increase accuracy of fulfillment in a cost-effective way. This technology automatically optimizes the method of delivery, inventory levels and transfers, and generates strategic fulfilment plans.

Advanced Warehousing

Advanced warehousing is in addition to your basic inventory functionality within Dynamics 365. And includes a variety of functionality including:

- Mobile device

- Wave processing

- Load planning

- Reservation hierarchy

- Inventory status

- License plates

- Flexible work creation

- Manual packing

- Containerization

- Cycle counting

- Transportation management

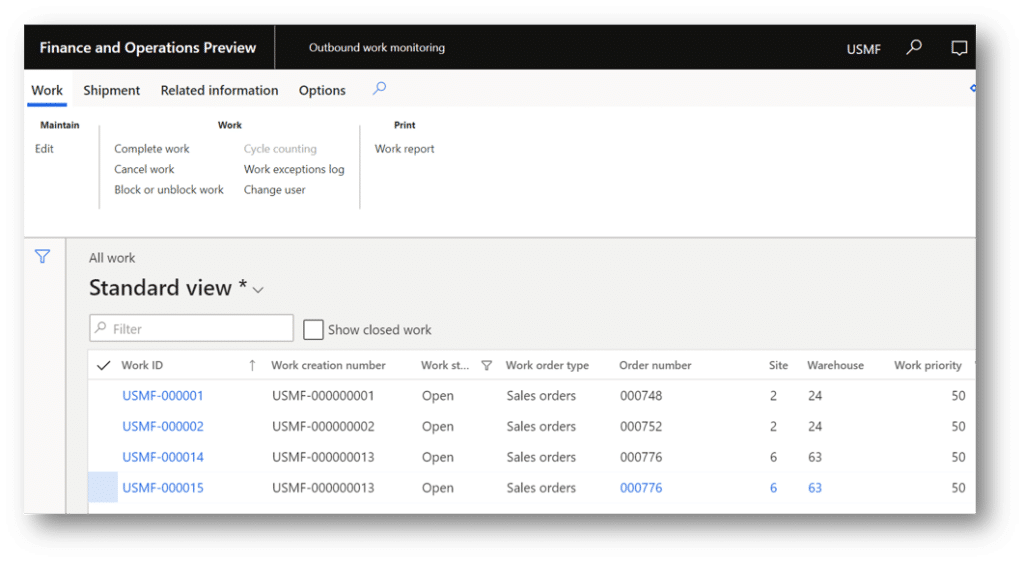

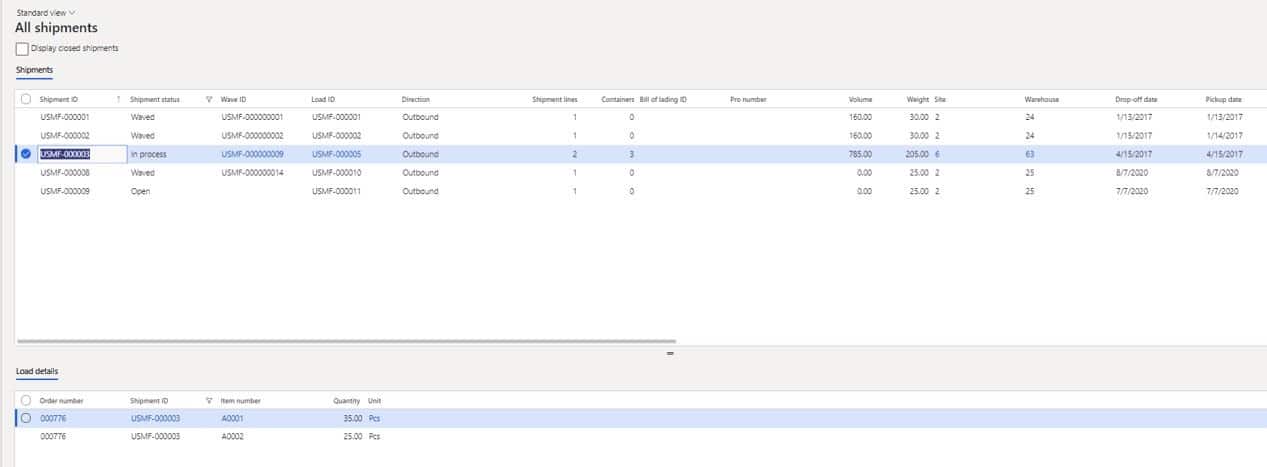

The shipment bench in advanced warehousing gives you the status of what is happening with the shipments, what is being processed, weighed, how many containers are being packed, shipping weights, etc.

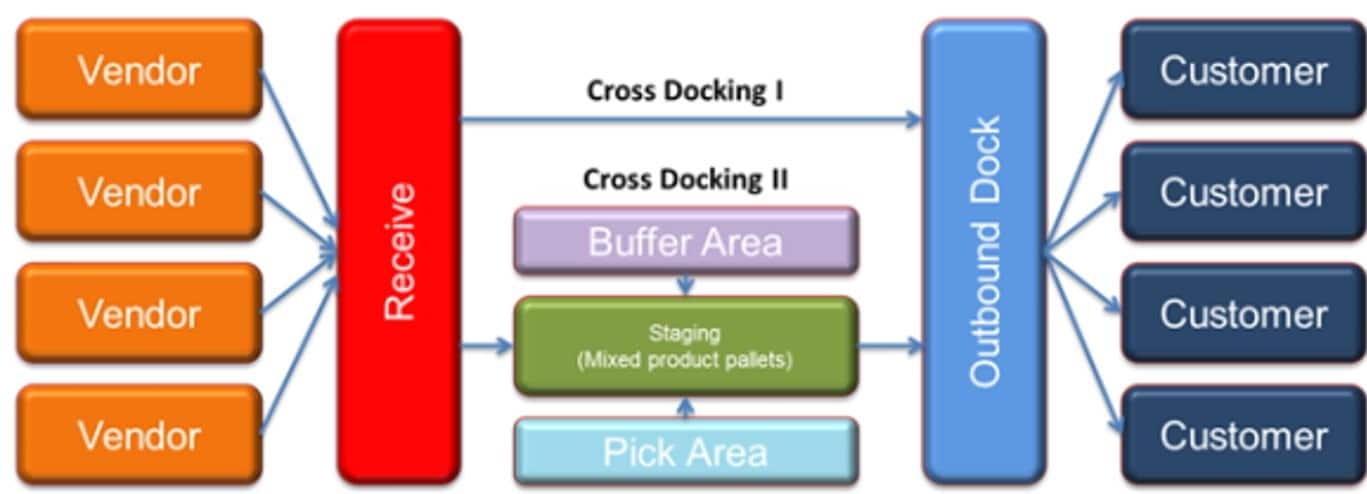

Another feature in advanced warehousing is cross-docking. Cross-docking allows you to short cut the normal process. The normal process is a vendor purchase order that comes through receiving, then is staged, shelved, and shipped. With cross-docking, purchase orders are taken straight to the outbound dock to be immediately shipped to the customer.

With Dynamics 365, your shipping and receiving department has tools and visibility into what is happening, what needs to happen, and the overall impact.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.