Overview of Lot Management Capabilities for Batch Manufacturers Using Dynamics 365 and ProBatch

Overview of Lot Management Capabilities for Batch Manufacturers Using Dynamics 365 and ProBatch

In order to have an FDA compliant ERP solution, you need to comply with specific regulations including item and lot tracking and tracing. Batch manufacturers, including pharma, chemical, and cosmetic manufacturers, can rely on Dynamics 365 and ProBatch to effectively track lots and manage inventory. This blog will provide an overview of the capabilities within the system that will help keep you in FDA compliance while streamlining your processes and becoming more efficient.

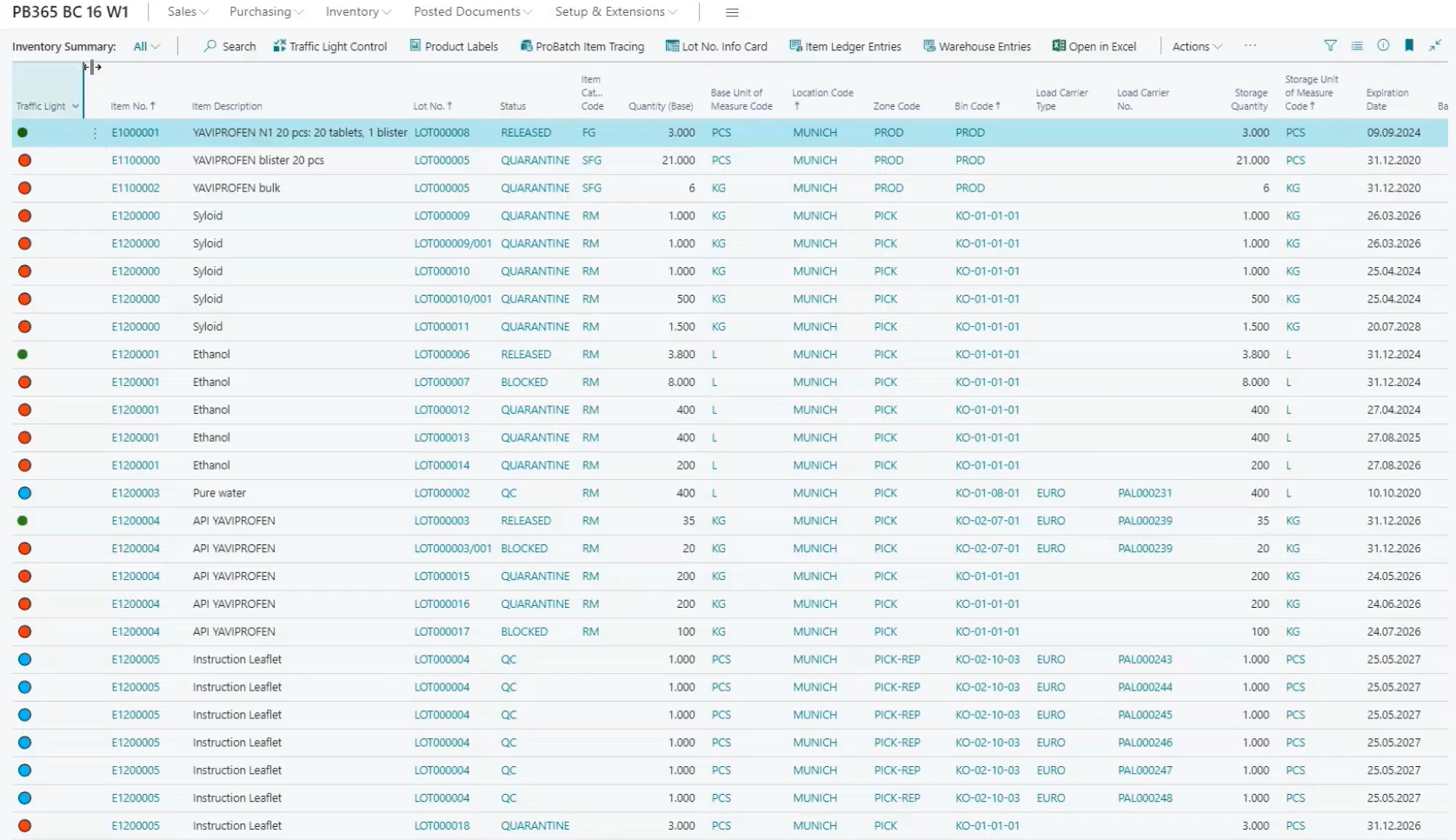

Inventory Management

From a single screen within the system, you can gain insights into your inventory including item categories, quantities, locations of inventory, bin locations, storage unit of measure and quantities, expiration dates, and more. The information is updated at any stage of the production process as long as the user has the appropriate permissions within Business Central.

Additionally, you have the ability to print product labels that can be printed on warehouse receipts directly from this window.

Item and Lot Tracking

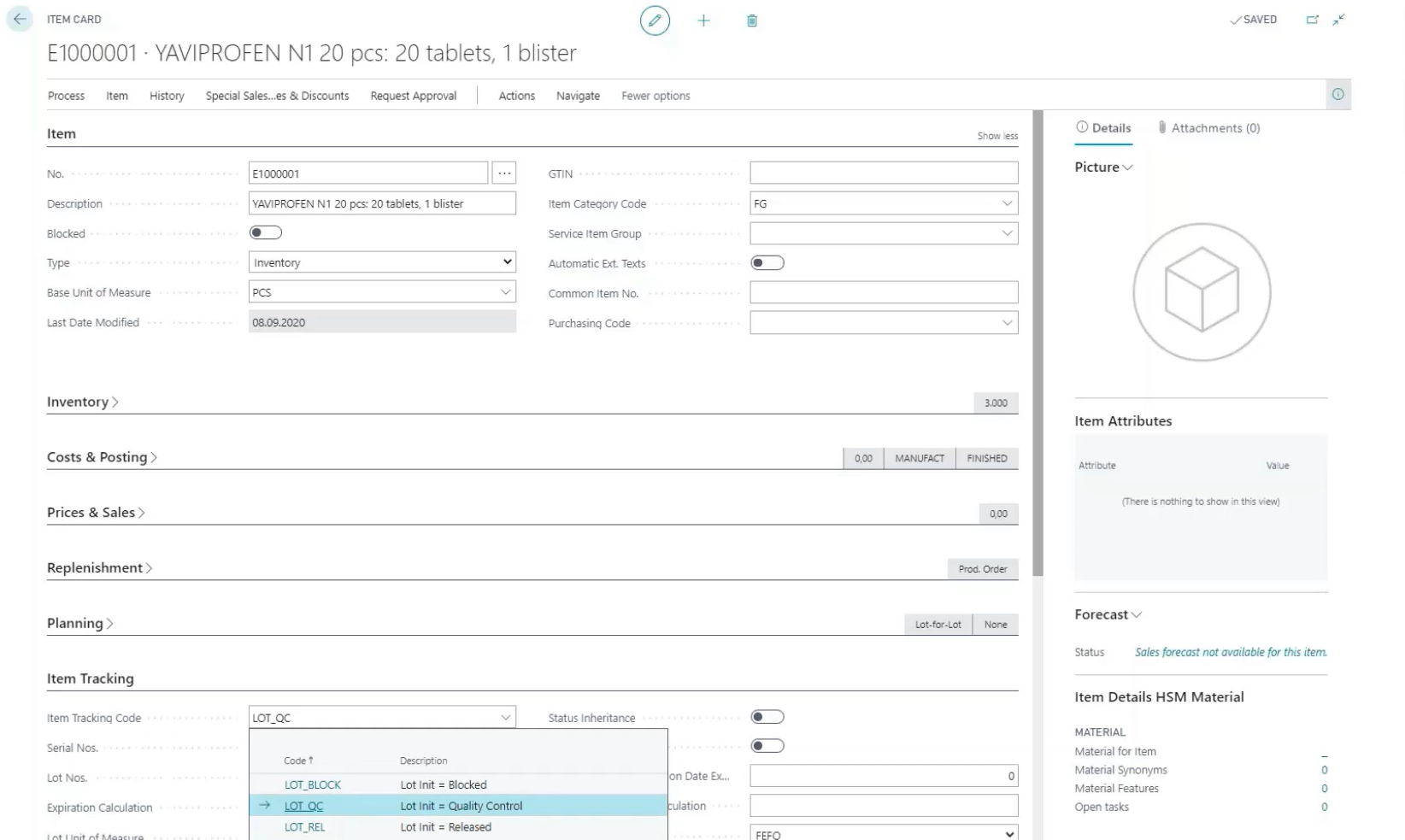

Each item within the system can be set up to include important details that help track its production status, location, and distribution details. On the item screen, you’ll see fields that allow you to input information related to:

- Item number

- Description

- Item type

- Base unit of measure

- Item category code

- Inventory details

- Pricing and sales information

- Item tracking code

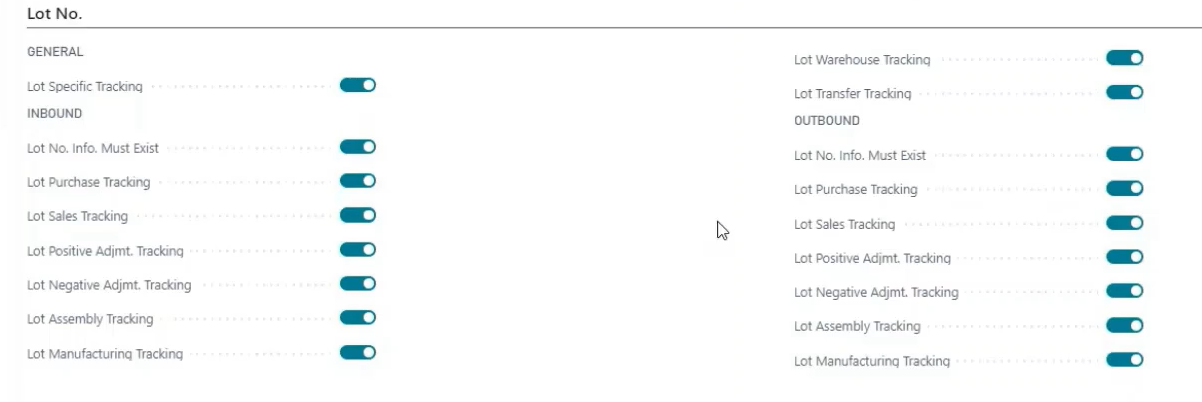

Depending on the item, you can set up the system to require lot tracking information during different areas of the manufacturing process. Additionally, you can set a default initiate status for items that include quarantine or released. This setting can then be used to build logic rules within the system in order to route each item to the correct stage of production.

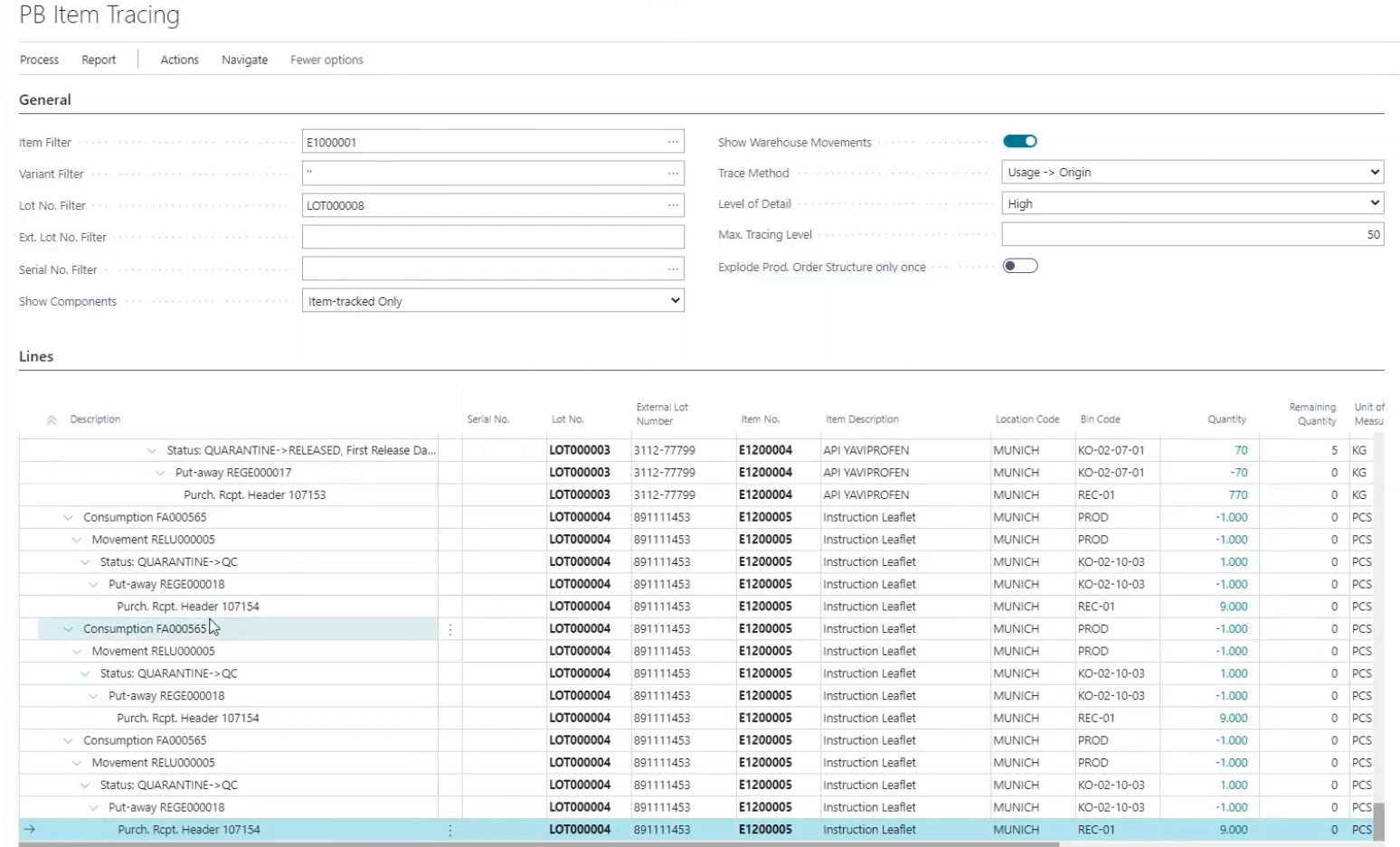

Item Tracing

Within BC you always have the latest real-time information related to item tracing. Simply by opening an item you can view the item’s entire history including output, consumption, and movement. Along with item details, you can view who made the update and at what time and date.

The item filter and lot filter can be used to filter items, types of tracing routes, warehouse movements, max tracing level, and more giving you control over the data you view.

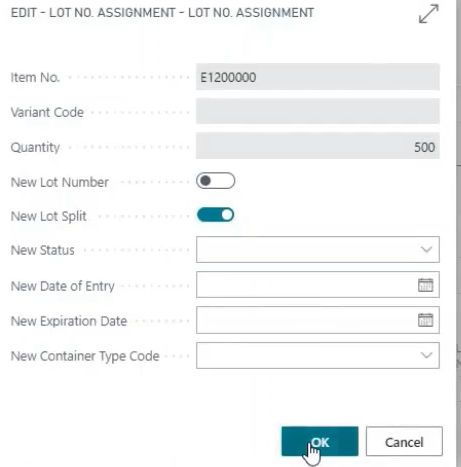

Lot Splitting and Merges

Within BC you can split or change inventory quantities as needed. For example, if a forklift operator makes an error and ruins part of an inventory batch, you could split those ruined products away from the lot. Additionally, you can merge lots together if need be. Both of these processes are completed with a quick input within the system. The new lots are then generated and updated for tracking purposes.

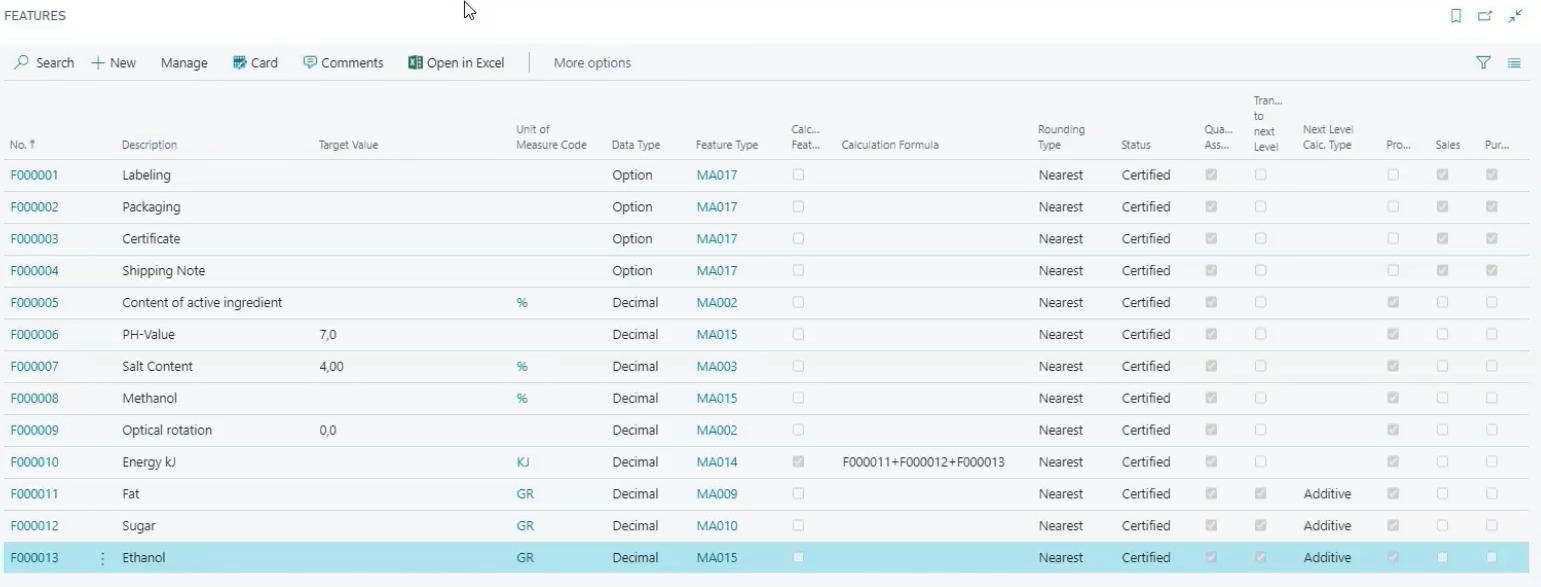

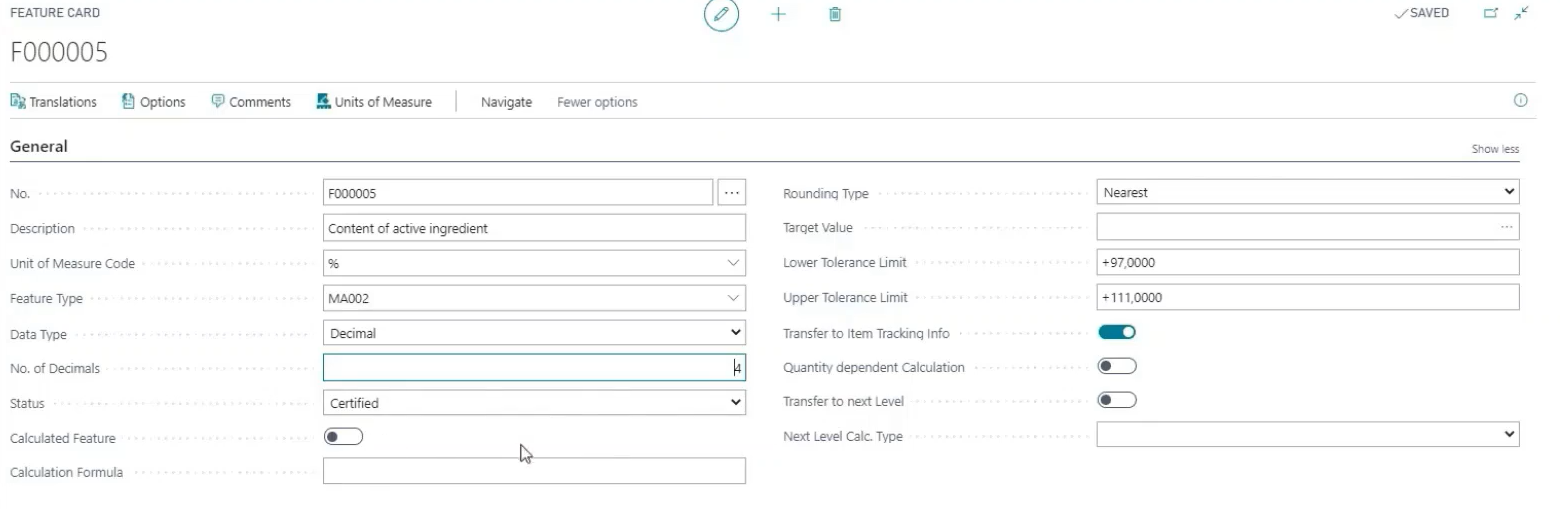

Managing Item Features or Components

The features list is completely customizable to your company and your needs. Each feature can be linked to any number of items and every single item can include any number of features.

Features are set up to include descriptions, feature types, units of measurements, data types, number of decimals, status, tolerance and control limits, and more.

Dynamics 365 Business Central with ProBatch is the ideal ERP solution for batch manufacturers because of the robust functionality within the system and the integration to the entire suite of Microsoft products. If you’re looking for an end-to-end solution for your manufacturing operation, reach out to the experts at Stoneridge Software to learn more.

You can also learn more about the lot management functionality by joining our upcoming webinar. If you’re unable to attend live, make sure to register to receive the recording.

Lot Management Best Practices for Batch Manufacturers

March 3

2-2:30 pm (CT)

Lot management is an integral part of the manufacturing process for all batch manufacturers, including both pharma and chemical. During this webinar, you’ll learn how Dynamics 365 and ProBatch can help even the most complex businesses with lot management. From container and serial number management to lot splitting and merging, you’ll see how a modern technology solution can help your operation become more efficient, effective, and accurate.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.