Dynamics AX 2012 Scheduling Options & Sorting Orders

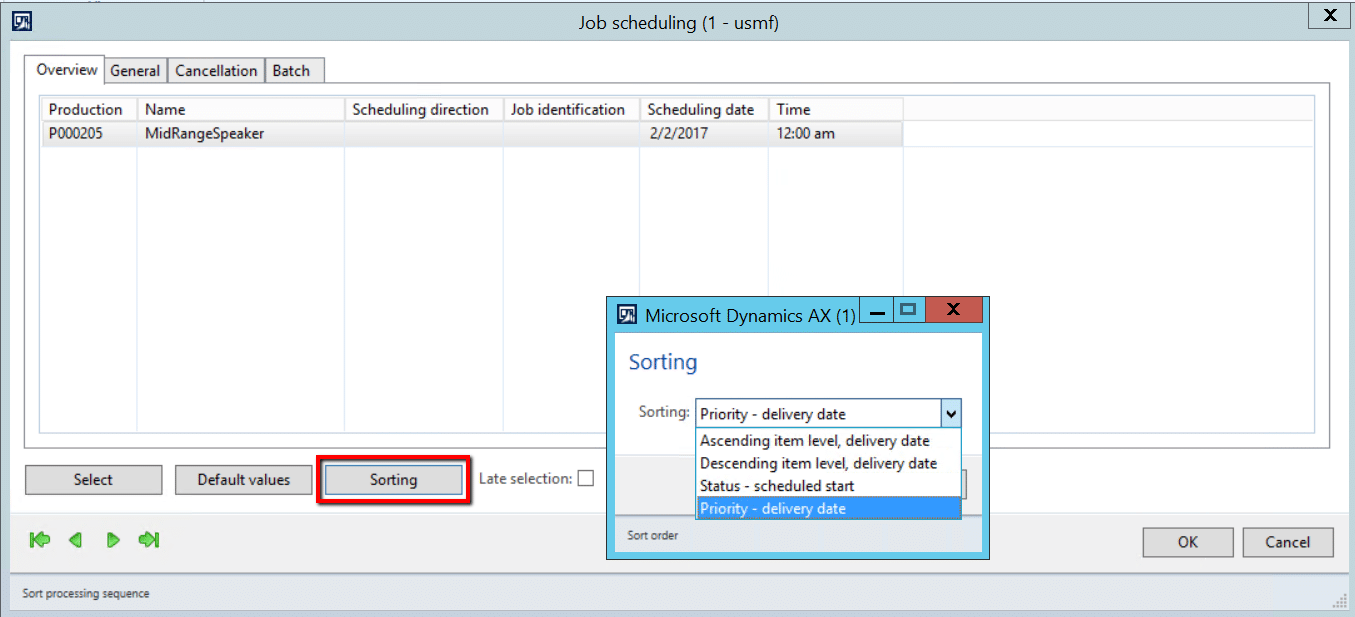

In Operation and Job Scheduling in Dynamics AX 2012, there are four options for sorting the order in which AX schedules production orders.

4 Options for Sorting Orders in Dynamics AX

- Ascending item level, delivery date

- Descending item level, delivery date

- Priority – delivery date

- Status – scheduled start

The first three scheduling options below start with the delivery date of the production order. Orders with the earliest delivery dates are scheduled first. If multiple production orders have the same delivery date AX will sort the production orders as outlined below.

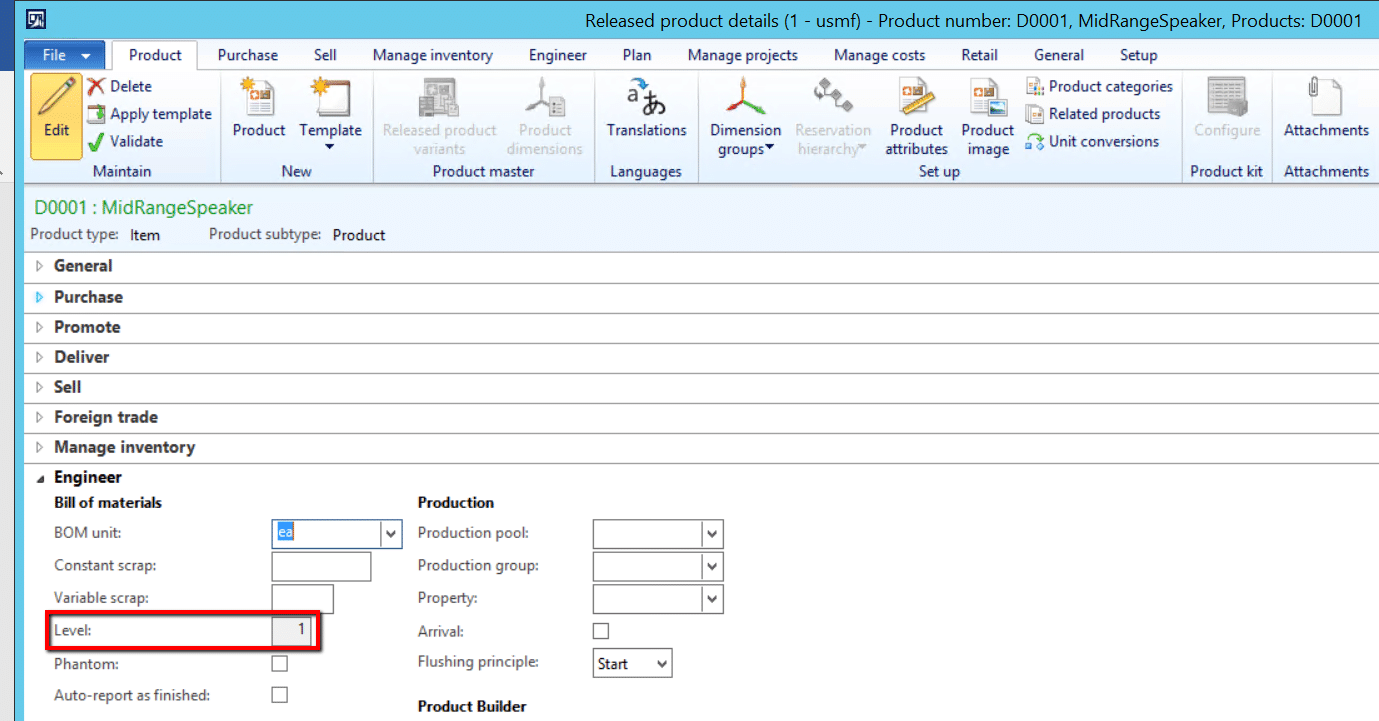

Ascending item level and Descending item level use the BOM level to determine the scheduling order

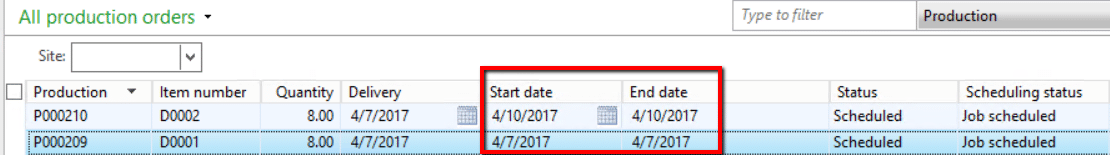

Ascending item level, delivery date will schedule items from the lowest BOM level to the highest. Finished goods are scheduled before Semi Finished goods (BOM items that are consumed by other BOMs).

In the example below, a Finished Good and a Semi Finished Good are being scheduled with the same delivery date.

Item: D0001 BOM Level 1 (Finished Good)

Item: D0002 BOM Level 2 (Semi Finished Good)

AX will schedule production order P000209 first because item D0001 has the lowest BOM level.

Few manufacturing scenarios would require Finished Goods to be scheduled before related Semi Finished Goods, so this approach is seldom used.

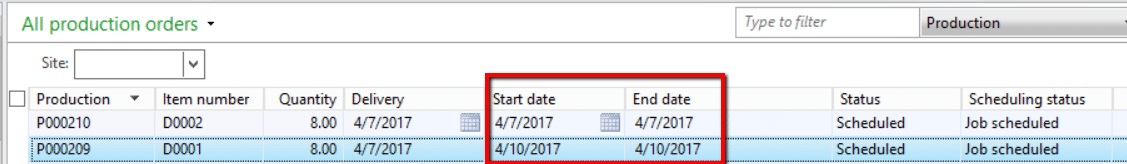

Descending item level, delivery date will schedule items with the highest BOM level to the lowest. Semi-Finished goods will be scheduled before Finished Goods.

In the example below, a Finished Good and a Semi Finished Good are being job scheduled with the same delivery date. Descending item level, delivery date has been selected.

Item: D0001 BOM Level 1 (Finished Good)

Item: D0002 BOM Level 2 (Semi Finished Good)

AX will schedule production order P000210 first because item D0002 has the highest BOM level

The opposite of the previous approach, this scheduling order is very commonly used.

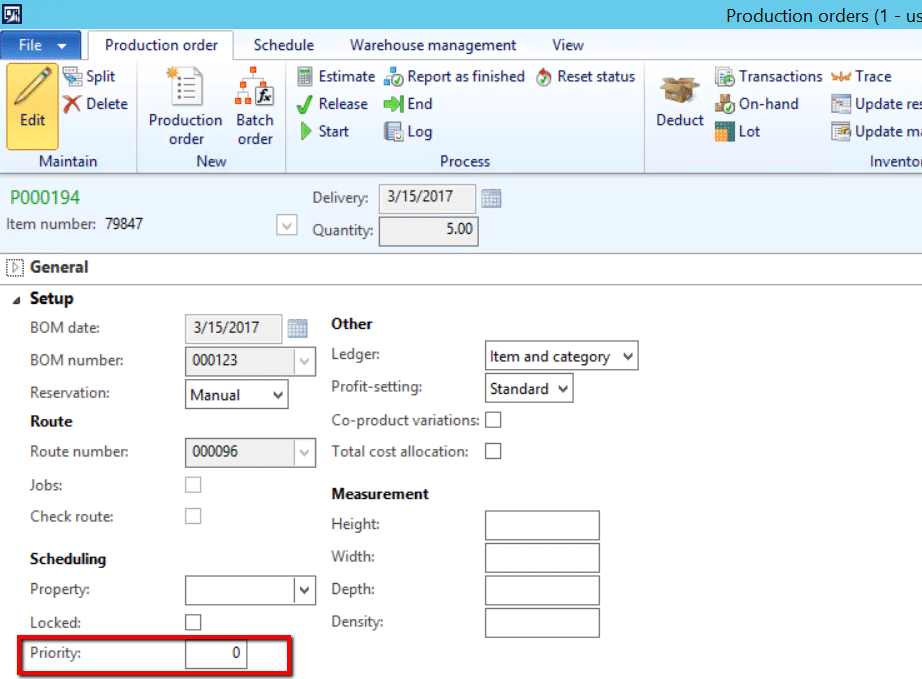

To schedule production orders by Priority – delivery date the priority field needs to be manually entered on the production order. The higher the number the higher the priority of the production order.

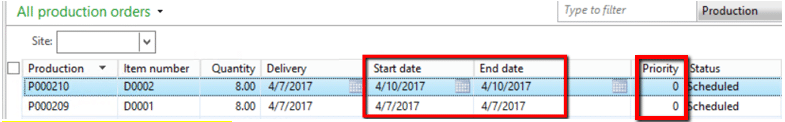

In the example below, I am scheduling two production orders with the same delivery date and the same priority.

AX will schedule production order P000209 first because AX will schedule the lowest production order number first

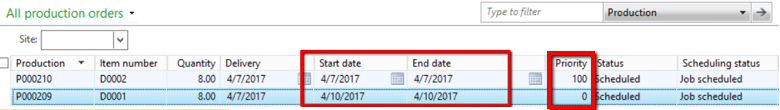

In the next example, I am scheduling two production orders with the same delivery date with priority on production order P0002010 set to 100.

AX scheduled production order P000210 first because it has a higher priority than P000209

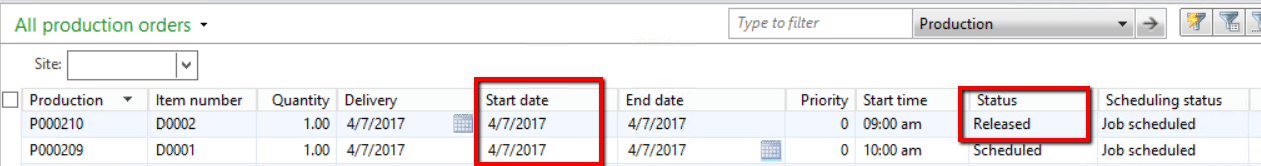

The last scheduling sorting option on AX is Status – scheduled start. If multiple orders have the same start date the production order in the higher production status will be scheduled first. Production order status from lowest to highest, Scheduled, Released and Started.

In the example below, the two production orders have the same start date. The order in the higher production status will be scheduled first. Production order P000210 is in a released status, released status is a higher status then scheduled. P000210 is scheduled to start at 9:00 AM compared to order P000209 which will not start until 10:00 AM.

Happy scheduling!

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.