Fill Entire Shipment in Dynamics AX Warehouse Management

What does the Fill Entire Shipment check box on the customer in Dynamics AX do and how does it work?

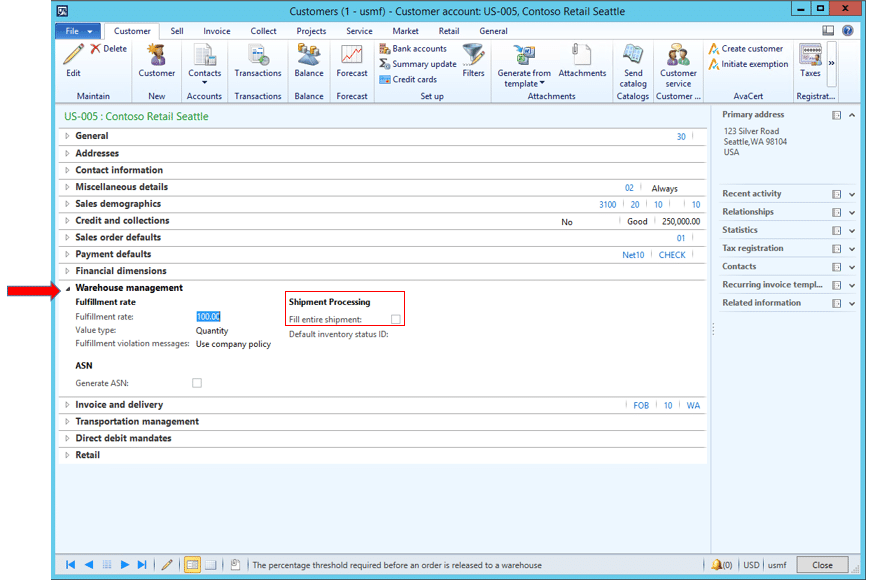

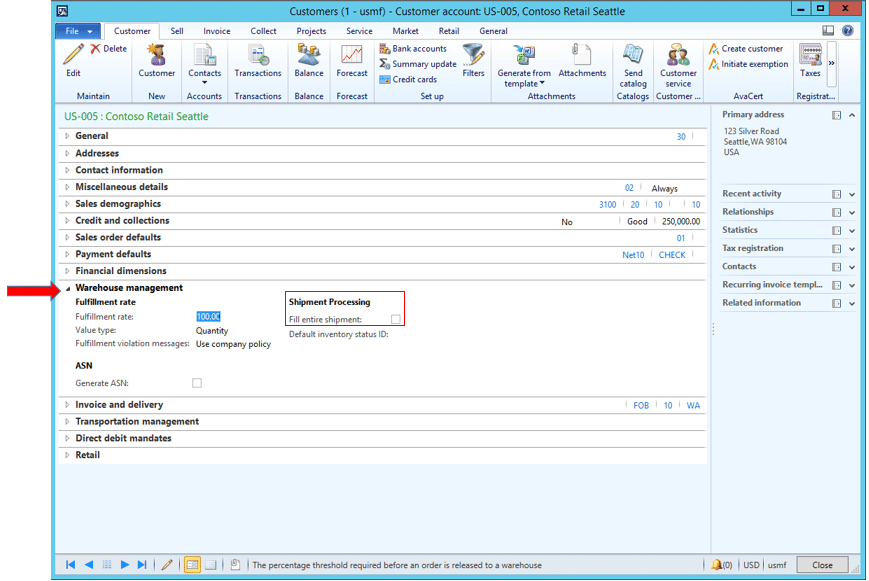

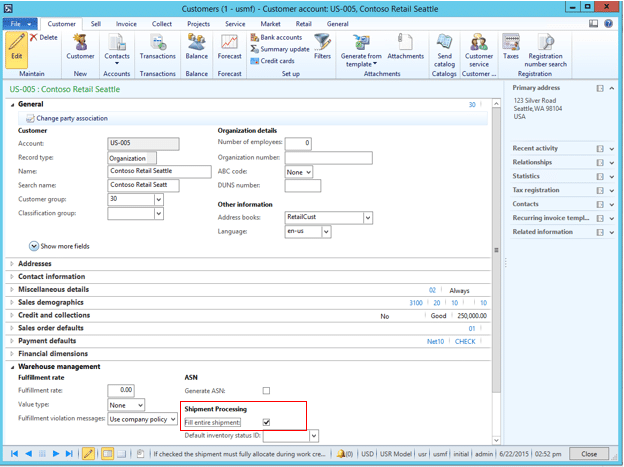

When you’re on the Warehouse Management FastTab on the Customers form, you’ll see a Fill entire shipment check box in the Shipment processing field group. (Accounts receivable > Common > Customers > All customers > Warehouse management FastTab).

If the Fill entire shipment check box is selected, this means that if the location directives for any work related to a shipment for this customer fail, no work will be created for the entire shipment. In other words, if the check box is selected, the shipment must fully allocate when the work transactions are created.

Here are a couple of examples to show how the Fill entire shipment check box works.

Example 1: Fill entire shipment check box is not selected

In this scenario:

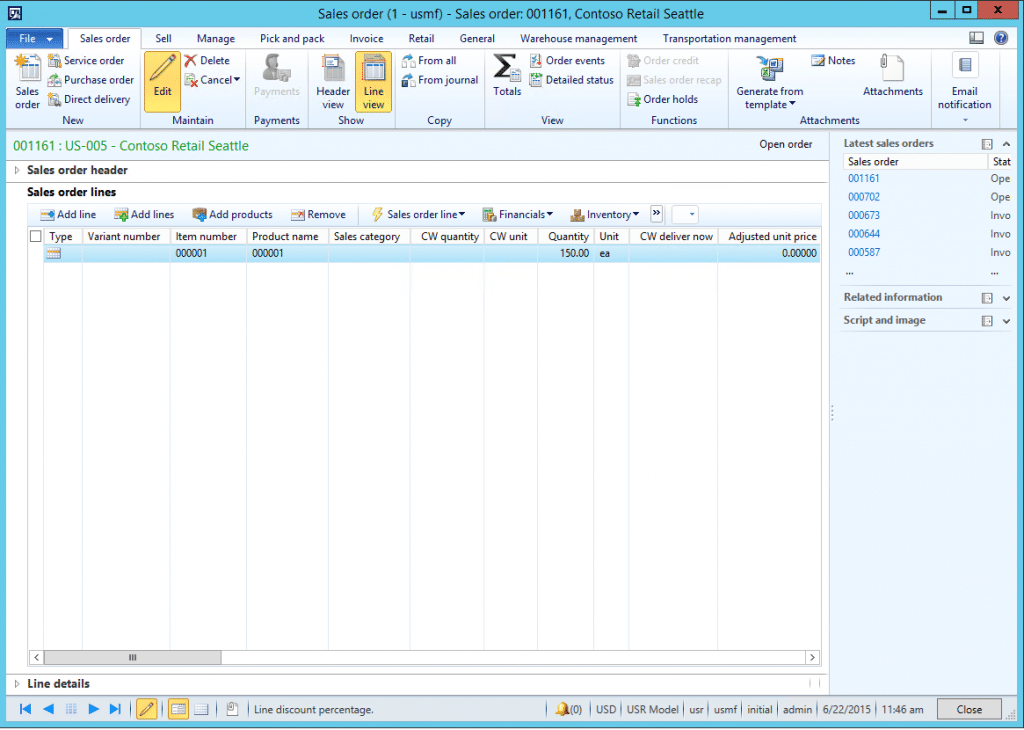

- A sales order for a quantity of 150 ea is entered for item number 000001

- There is a total Available physical quantity of 200 ea in the Pick and Bulk locations in the warehouse

- The location directive is set up to only pick from “picking” locations, not bulk

- Demand replenishment is not being used

Item number: 000001

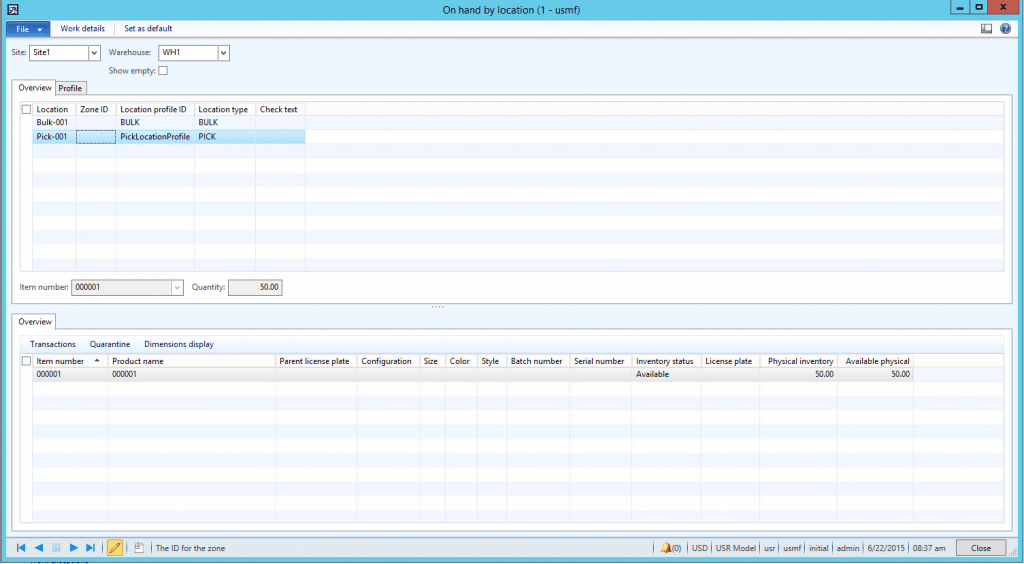

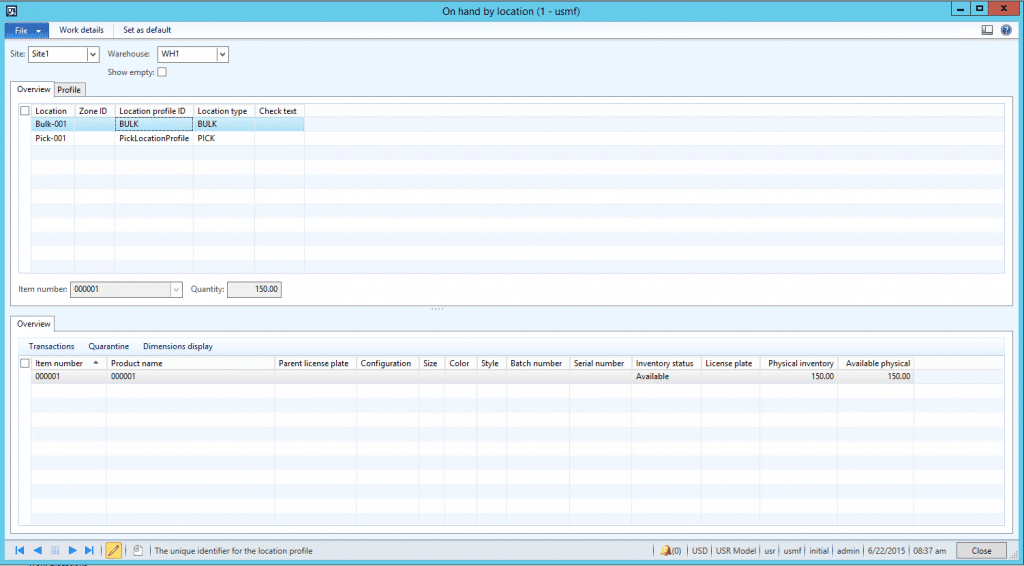

Quantity on hand in the warehouse:

Pick-001: 50 ea

Bulk-001: 150 ea

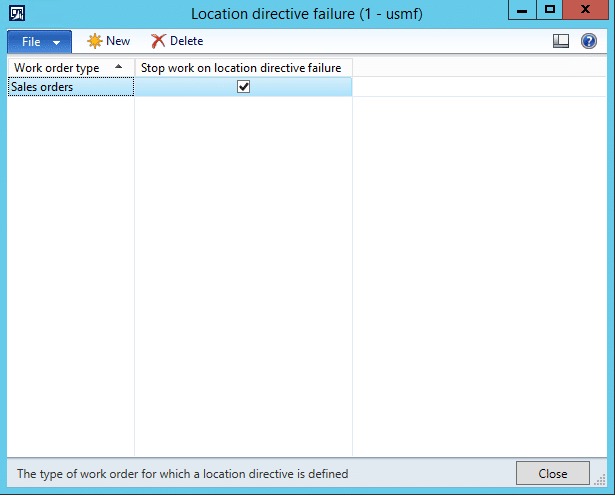

In this example, location directive failures are enabled. (Warehouse management > Setup > Work > Location directive failures). The Stop work on location directive failure check box is selected for sales orders. This means that if any of the location directives fail and can’t find a location to pick from, then no work will be created for that quantity to be picked.

Note: There’s a great blog post about location directive failures and how they work on the Microsoft Dynamics AX Community site that you can find here.

The Fill entire shipment checkbox is not selected on customer US-005 – Contoso Retail Seattle.

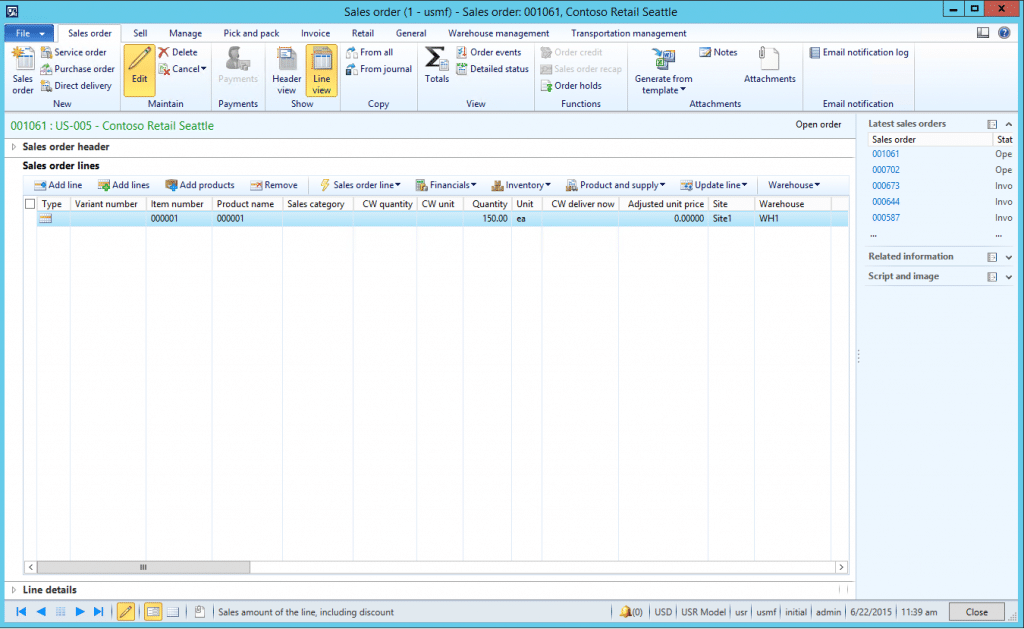

A sales order is entered for item number 000001 for a quantity of 150 ea and 150 ea are automatically reserved.

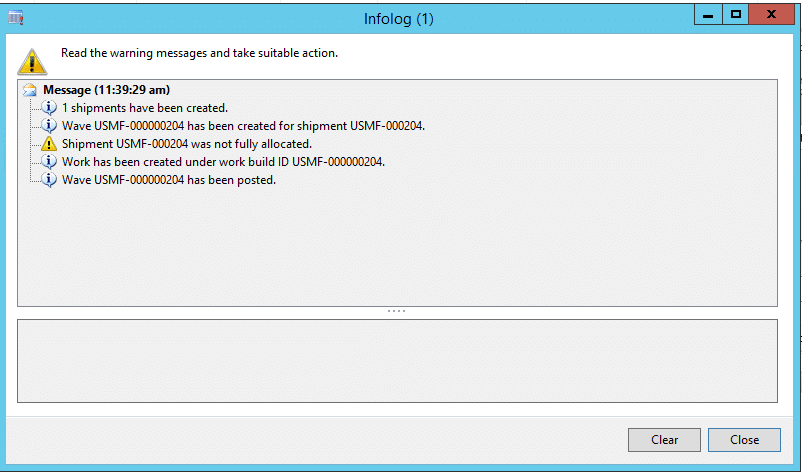

When the sales order is released to the warehouse, an Infolog is displayed.

It tells you that:

- Shipment USMF-000204 was not fully allocated

- Work has been created

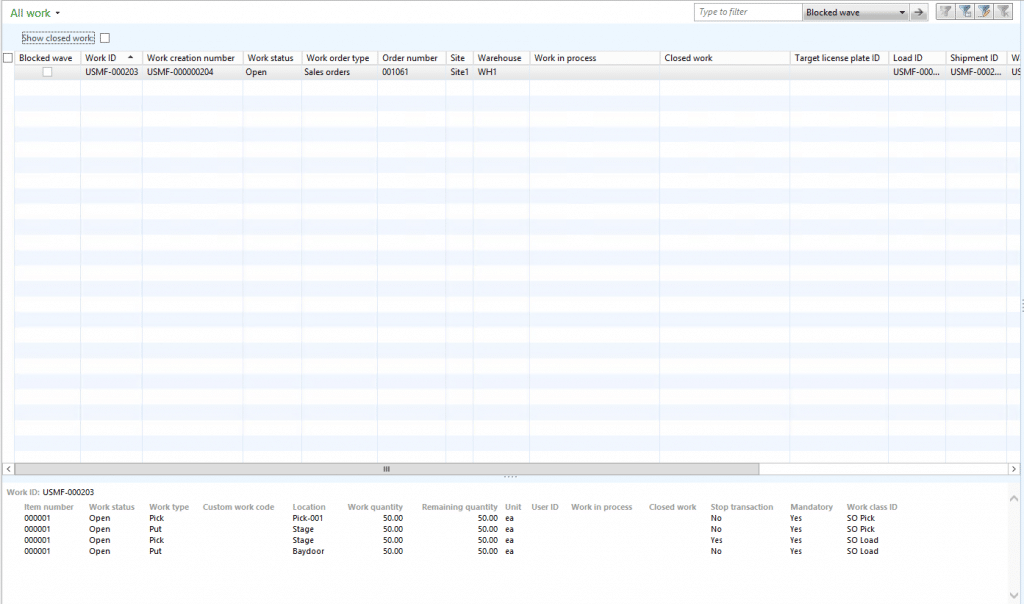

If we go in and look at the work that was created (Warehouse management > Common > Work > All work), the work quantity is for 50 ea, not 150 ea.

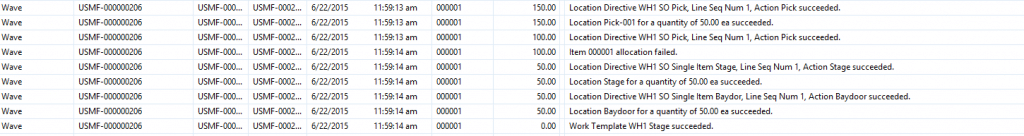

The Work creation history log (Inquiries > History > Work creation history log) shows us that a pick from location Pick-001 for a quantity of 50 ea succeeded, the Put to location Stage and the Put to location Baydoor for 50 ea both succeeded, and item allocation for 100 ea failed.

Since the Fill entire shipment check box wasn’t selected, AX still created work for the quantity of 50 ea that was available in the Pick-001 location.

Here’s what would happen in the same scenario if the Fill entire shipment check box is selected:

Example 2: Fill entire shipment check box is selected

In this scenario:

- A sales order for a quantity of 150 ea is entered for item number 000001

- There is a total Available physical quantity of 200 ea in the Pick and Bulk locations in the warehouse

- The location directive is set up to only pick from “picking” locations, not bulk

- Demand replenishment is not being used

In this example, location directive failures are enabled. (Warehouse management > Setup > Work > Location directive failures). The Stop work on location directive failure check box is selected for sales orders. This means that if any of the location directives fail and can’t find a location to pick from, then no work will be created for that quantity to be picked.

The Fill entire shipment checkbox is selected on customer US-005 – Contoso Retail Seattle.

A sales order for a quantity of 150 ea is entered and 150 ea are automatically reserved.

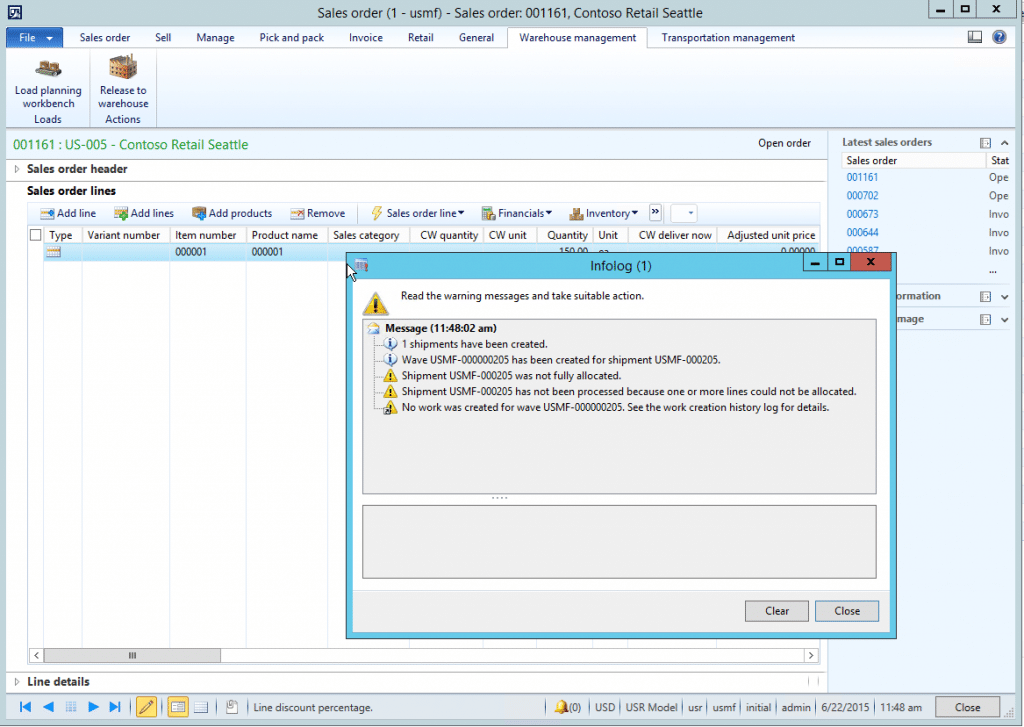

When the sales order is released to the warehouse, the following Infolog is displayed:

It tells you that:

- Shipment USMF-000205 was not fully allocated

- Shipment USMF-000205 has not been processed because one or more lines could not be allocated

- No work was created

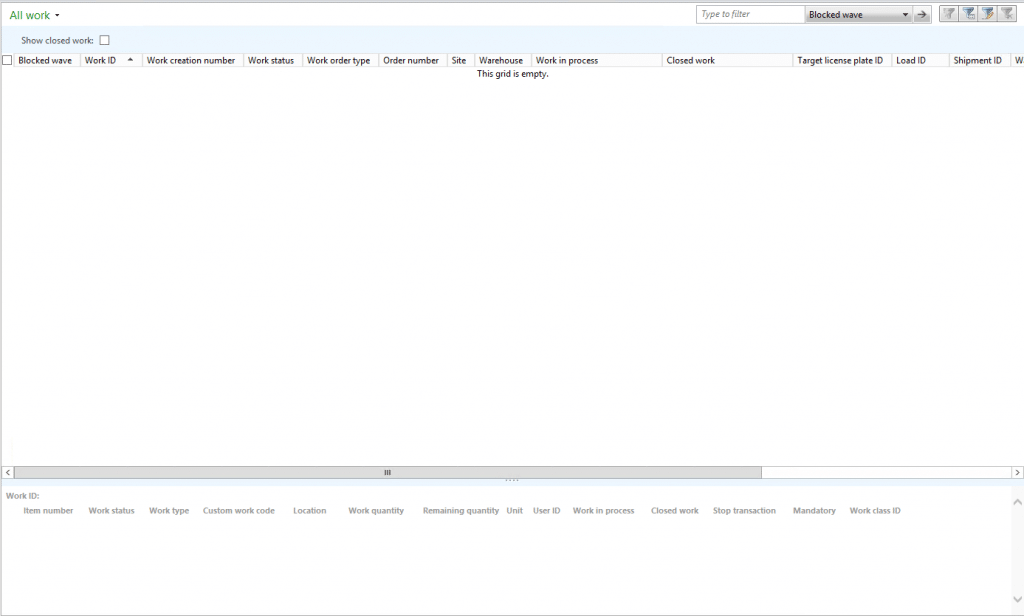

If we go in and look at the work that was created (Warehouse management > Common > Work > All work), no work was created even though we know 50 ea out of the 150 ea ordered are available in location Pick-001.

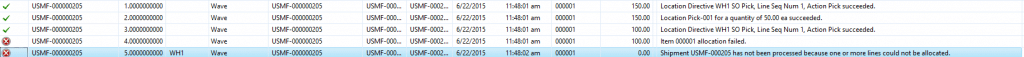

The Work creation history log (Inquiries > History > Work creation history log) shows that the location Pick-001 for a quantity of 50.00 succeeded, item allocation for 100 ea failed, and then Shipment USMF-00025 was not processed because one or more lines could not be allocated.

Since the shipment couldn’t fully allocate the entire shipment for a quantity of 150 ea, no work was created.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.