How Manufacturing Buyers can Achieve Procurement Goals with Dynamics 365

Buyers at manufacturing companies are responsible for sourcing potential suppliers, negotiating prices and terms, and making agreements or contracts for purchases. A key component of their role is to procure the best possible price for goods that meet the quality standards and parameters of the organization.

Within Dynamics 365 Finance and Supply Chain Management, buyers have the ability to requests quotes, access pricing information, history, and agreements, maintain quality control, and access historical data. This article will cover each of these components and how Dynamics 365 helps buyers achieve their procurement goals.

Request for Quote

Within Dynamics 365, manufacturing buyers can initiate a request for quotations from vendors. This allows the vendor to provide prices and delivery times for the item quantities that you’re looking for. You also have the option to request other details that may impact the final cost of the purchase including incidental costs like shipping, or any discounts available based on quantity purchased or early payment with the vendor.

This request can be initiated from planned purchase orders generated through Material Resource Planning (MRP), through purchase requisitions, or by manual entry.

When these are generated, they can be emailed directly to the vendors you’d like to receive quotes from. Additionally, you can automatically include a response sheet in the same email.

Dynamics 365 includes a portal option that allows you to collaborate with your vendors on item requests, availability, pricing, and more. Information flows directly from Dynamics 365 to and from the portal, so there is no manual entry or additional work. You simply provide your vendors a unique log-in and they have access to submit responses to your requests directly into the portal and Dynamics 365.

Without a portal, responses for requests for quotations are manually entered into Dynamics 365, recorded against the quotation, and scored manually.

If you’re familiar with Dynamics 365, you’ll know there are a variety of different pre-set workspaces available for different job roles. One of those workspaces is a vendor bidding area where you can track the various stages of the RFQ process for each unique vendor.

This video shows how the request for quotation functionality works directly in Dynamics 365 Finance and Supply Chain Management.

Pricing Hierarchy

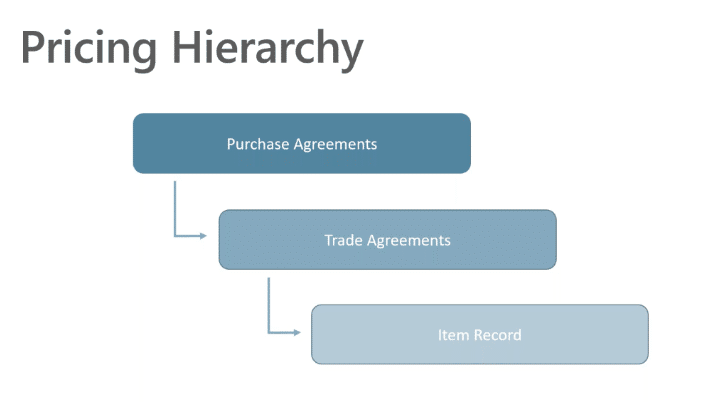

Dynamics 365 has three different pricing options available that follow a pricing hierarchy (Figure 1). The lowest level of the hierarchy is the item record, next is the purchase trade agreement and lastly, the purchase agreement overriding both the trade agreement and item record pricing.

Figure 1

Item Record

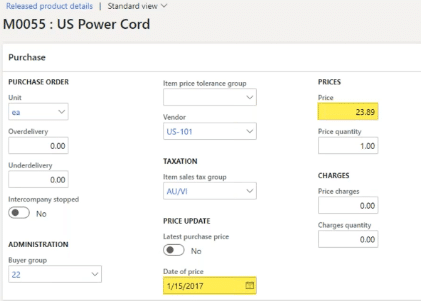

There are two ways the item record price can be updated, manually, or with the use of the Latest purchase price flag from the item record (Figure 2). When the latest purchase price flag is set to No all updates the Price and Date of price field are manual. When the latest purchase price flag is set to Yes, the most recent invoiced price and date are updated on the item record. This provides the user with clear visibility of when the price changed last.

Figure 2

The downside of recording pricing on the item record is the inability to see any historical pricing and the inability to apply discounts or price breaks for the item.

Trade Agreement Pricing

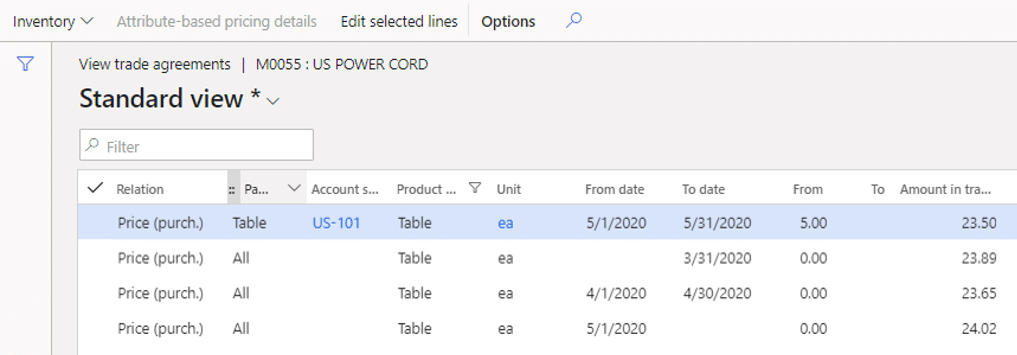

Purchase trade agreements allow you to set standard pricing for all products within Dynamics 365. With trade agreement pricing you can see historical pricing and gain a better understanding of when prices will fluctuate, enabling you to better predict and strategize when to purchase specific items. Trade agreement pricing allows you to input global pricing, discounts, quantity breaks, group pricing, or vendor-specific pricing. This information is automatically taken into consideration when you search for specific quantities of items, so you will always see the most accurate price available.

Each line item within trade agreements is entered through a journal entry and includes both the date the price was initially entered and when the price expires. The system automatically picks the correct price per item based on time frames listed (Figure 3).

Figure 3

If no expiration date is listed, that price will be applied on an ongoing basis until otherwise noted in the system.

There are a couple of downfalls in trade agreements. They do require maintenance to keep the prices up to date and they require users to click into the trade agreement link to view item pricing.

Purchase Agreements

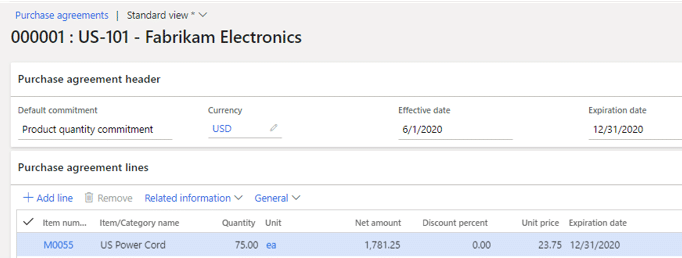

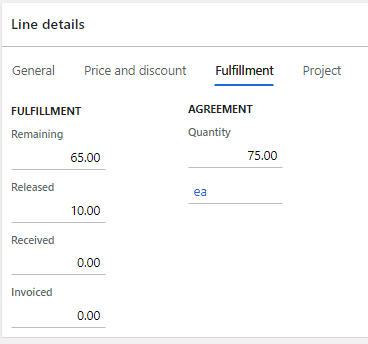

Purchase Agreements allow you to provide contractual pricing with each vendor. You have the ability to commit to a certain quantity with a supplier, and track your purchases against that minimum requirement as orders are generated. Each trade agreement has a start and end date and identifies which items are under agreement and at what price.

Once the expiration date has passed for the purchase agreement, the system defaults to the trade agreement, and if there is no trade agreement pricing configured for the item, the item record pricing defaults (Figure 4).

Commitments can be tracked for both quantities and the value of the agreement (Figure 5).

Figure 4

Figure 5

Some drawbacks for purchase agreements include the manual data entry of the purchase agreement, requirement for purchase orders to be created from the agreement, and no options for quantity breaks.

Maintaining Quality Control

It’s important to maintain quality control as products are coming into your production environment. Dynamics 365 has a variety of capabilities to help ensure the highest level quality – including test instruments, test variables, test groups, quality associations, item sampling, and more. The quality process can automatically be started based on predefined criteria in the system. For example, it could begin upon warehouse registration of a purchase order from a specific vendor, products in specific groups, or individual items. The system offers broad flexibility for you to decide when and with what items you’d like to start tracking quality.

Some of the other customizable quality control steps available within Dynamics 365 include:

- Create quality orders for full or partial receipts

- Block inventory during inspection to prevent non-approved inventory from being used (full blocking of purchase order quantities)

- Use item sampling as part of a quality association to define the amount of current physical inventory that must be inspected

- Sampling can be based on fixed quantities, a percentage, or full license plate (pallets)

- Create test types that include minimum, maximum, and target test values, and perform qualitative-versus-quantitative testing that has predefined validation results (acceptable quality level (AQL) measure tolerances)

- Specify the resources that an inspection operation requires, such as a test area and test instruments.

Insights into Historical Data

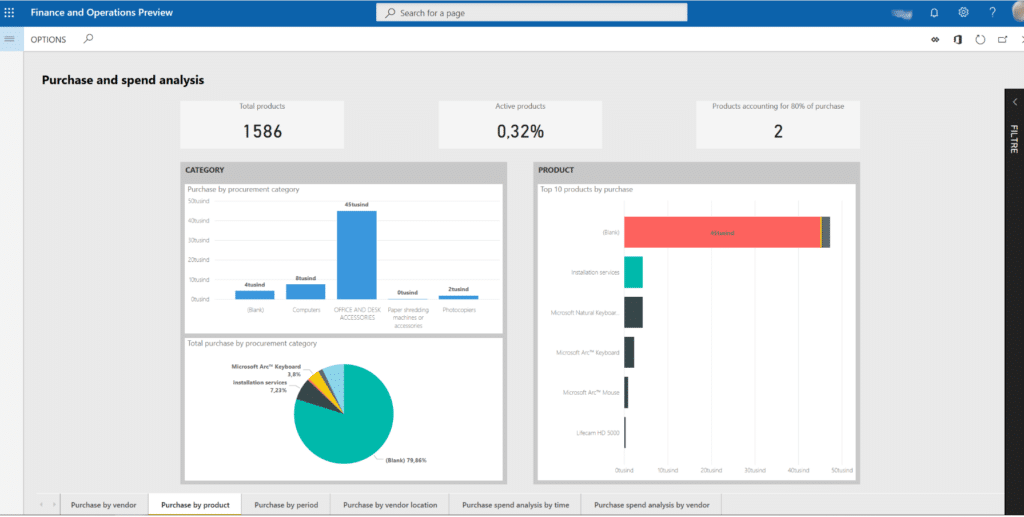

Workspace tiles in Dynamics 365 provide you with different areas to drill into to provide different data sets. For example, you can drill into purchase order preparation information, vendor bidding, and many more. Each of these areas are customizable so you can choose the information most important to you.

A variety of reports are available out of the box that can help you visualize your data without having to manually compile information from various sources. Additionally, Power BI capabilities give you the ability to generate charts and graphs with information directly from Dynamics 365.

To learn more about how Dynamics 365 helps buyers at manufacturing companies contact the experts at Stoneridge Software.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.