How to Tackle Research and Development Project Management with Dynamics 365 ERP Solutions

Effectively addressing research and development project management can be complex, but having advanced tools to simplify these processes makes a significant difference.

Microsoft Dynamics 365 Business Central, enhanced by YAVEON ProBatch, enables you to capture costs, manage formulas and recipes, and build detailed cost models that drive profitability.

In this blog, we’ll explore how to leverage the Business Central project accounting module and YAVEON ProBatch Research and Development (R&D) and costing extensions to:

- Accurately capture product development and setup costs, with the option to bill them back to customers.

- Manage new formulas and recipes while building comprehensive cost estimates, including overhead.

- Develop product pricing based on detailed cost analysis and desired margins.

It’s important to note that the features outlined in this blog are part of Business Central Premium Edition, which has built-in manufacturing functionalities and integrates with the extended capabilities of YAVEON ProBatch.

Let’s start by closely examining tracking development and setup costs.

Capturing Product Development and Setup Costs

When developing a new product or making changes to an existing one, accurately tracking development and setup costs is essential for fully understanding your investment and managing profitability. Business Central and YAVEON ProBatch provide robust tools to help you structure and capture these costs effectively—whether for internal tracking or for billing customers directly. Here are some features worth highlighting:

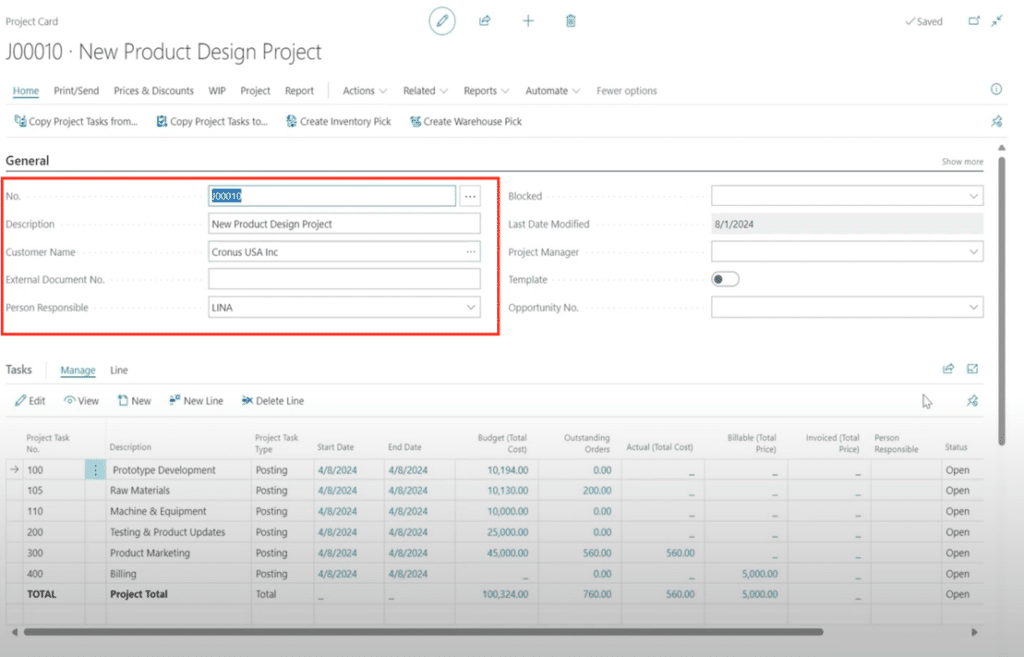

Within Business Central’s Project Accounting module, you can create and manage projects with a clear breakdown of tasks, budgets, and costs. Projects are structured with a project number, description, and customer assignment, and tasks serve as the building blocks for categorizing expenses and revenues. Also, Business Central allows you to copy templates to streamline project setup, saving time and ensuring consistency.

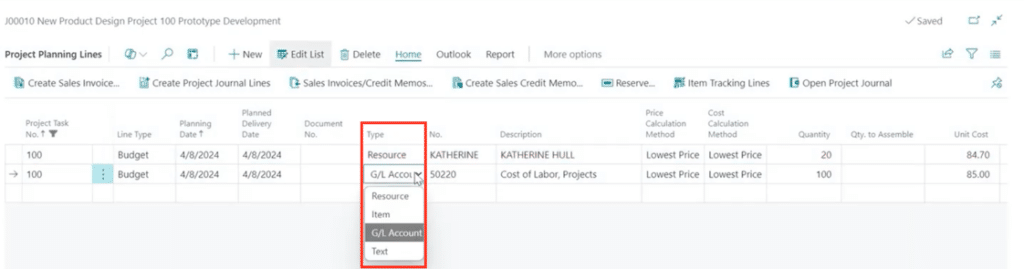

For each task, you can define a budget using planning lines. These lines provide flexibility to capture costs across multiple dimensions:

- Resources: Allocate labor costs for specific team members or general roles.

- GL Accounts: Track external expenses, such as agency fees, equipment rentals, or advertising costs, ensuring they are tied directly to the project.

- Items: Include materials or components that may be required for development, such as parts for prototyping or production testing.

In addition to budgeting costs, you can assign billable amounts for scenarios where a customer charges development efforts back. Whether it’s a flat fee or calculated rates for labor or materials, Business Central provides a seamless way to associate costs with revenue.

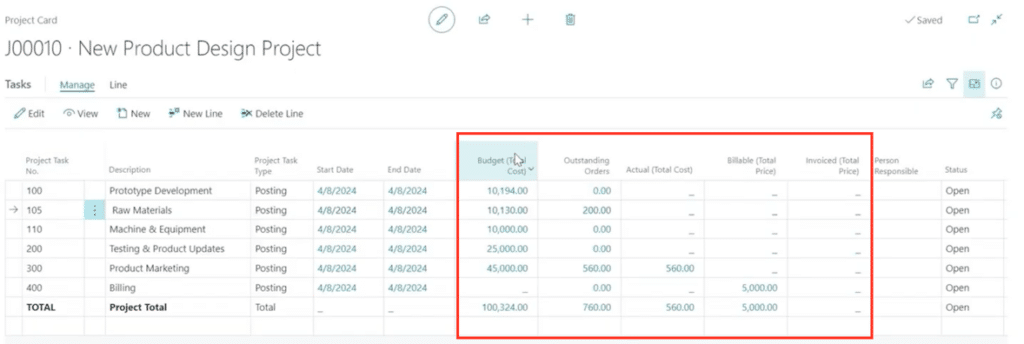

Once set up, the system enables you to monitor project activity in real time:

- Outstanding Orders: View pending transactions, such as purchase orders or time entries in progress.

- Actual Costs: Track posted transactions, including AP invoices, labor entries, and material purchases.

- Billable Amounts and Invoiced Costs: Monitor revenue budgets and actual billing against the project.

These tools provide visibility into your total project costs, allowing you to analyze expenses and ensure accurate tracking throughout the R&D process. Whether you’re capturing internal costs or billing customers for development work, Business Central and YAVEON ProBatch deliver the structure and flexibility needed to manage product development effectively.

Setting Up Flexible Pricing and Tracking AP Costs

Business Central offers flexible pricing options, allowing users to set up adaptable price lists for resources, inventory, and direct expenses with billing methods like flat fees, cost-plus markup, or time and materials. For product development, R&D items and development recipes provide a controlled environment to experiment, track costs, and refine processes without affecting production workflows.

Together, these features streamline project expense management while fostering innovation and efficiency.

Flexible Pricing Options for Projects

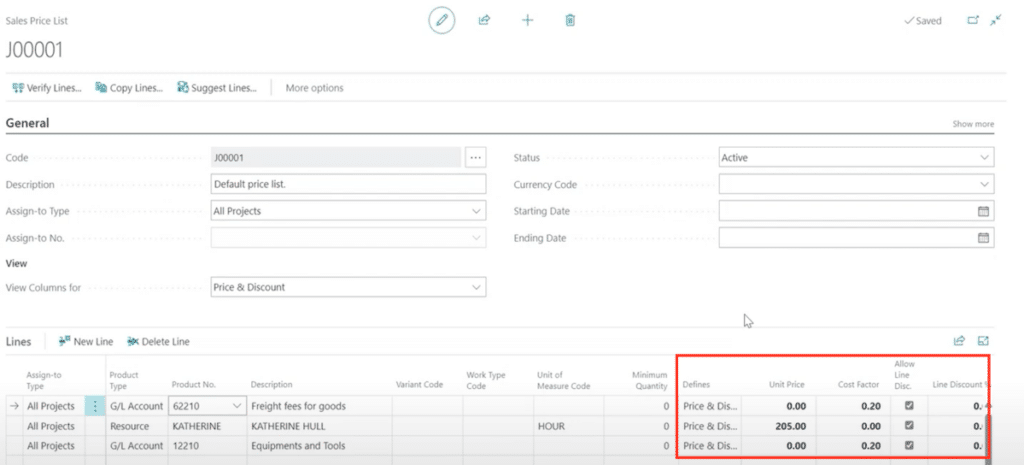

Business Central allows you to set up flexible price lists that adapt to various scenarios when managing project costs and billing. You can define pricing for resources (individuals or resource groups), inventory items, and direct expenses like freight. These price lists support multiple billing approaches:

- Flat Fee: A single fixed charge for the entire project or task.

- Cost-Plus Markup: Ideal for direct expenses, where a predefined markup is applied to costs.

- Time and Materials (T&M): Costs accumulate based on labor, inventory, or expenses consumed on the project.

This flexibility ensures that whether you’re billing for resource hours, inventory consumption, or incidental costs, you can configure pricing to suit your project’s needs.

Capturing Costs through AP Invoices and Purchases

To streamline cost tracking, Business Central integrates project expenses with Accounts Payable (AP) and purchasing processes.

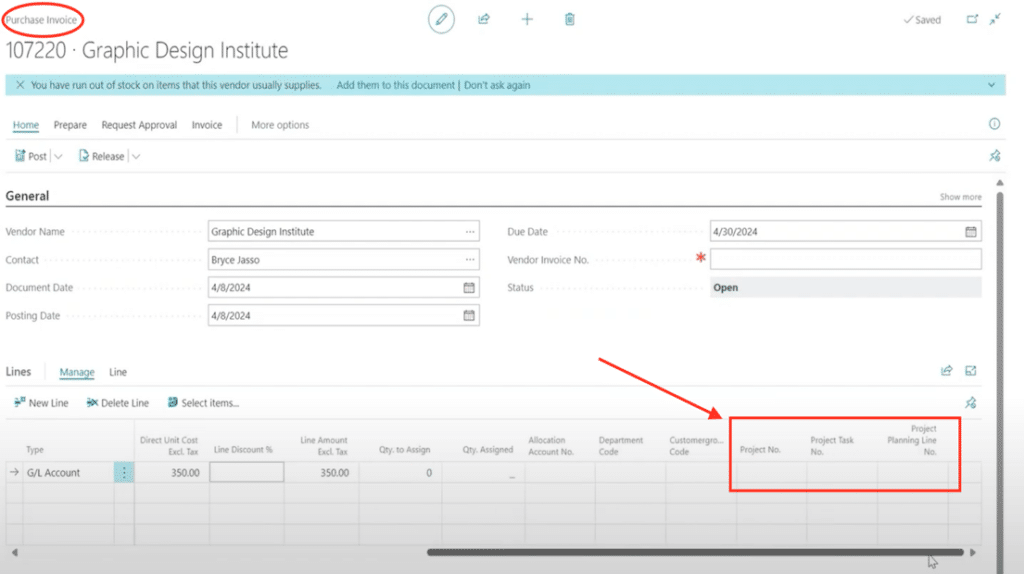

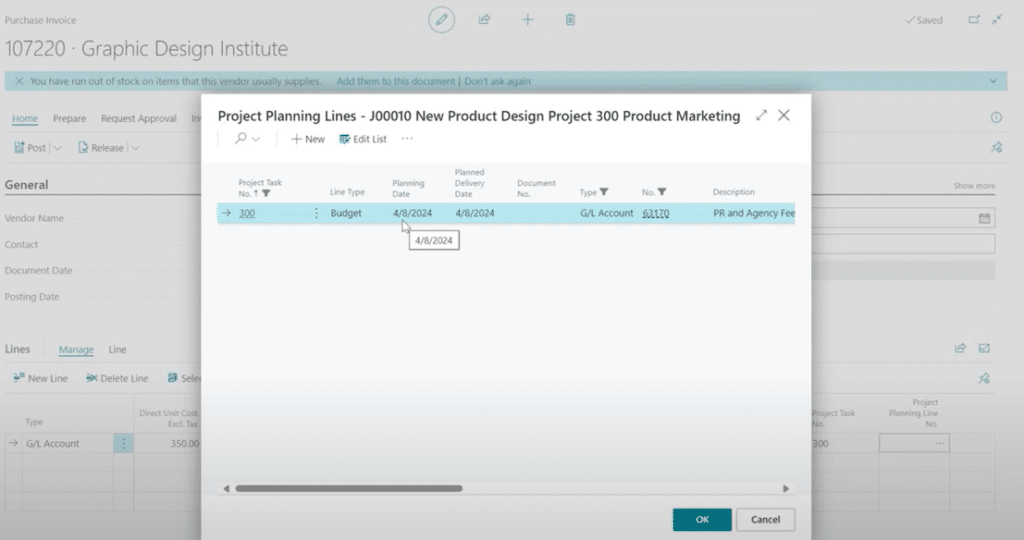

- AP Invoices: When entering a vendor invoice, you can assign costs to a specific project task and planning line. This ensures the expense is tracked against your project’s budget.

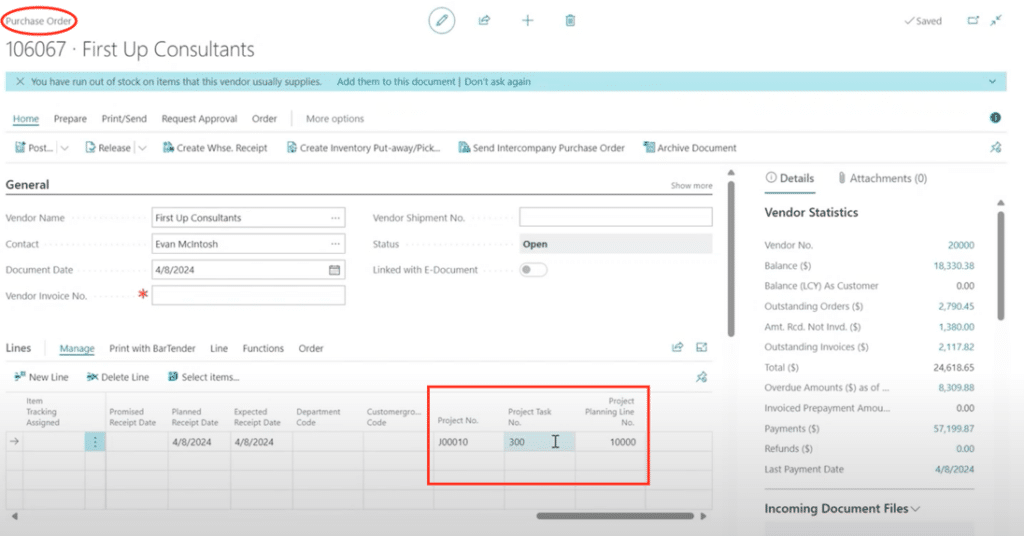

- Purchase Orders: Purchase orders offer a similar setup, enabling you to commit costs to a project task before they are invoiced. This visibility helps monitor outstanding commitments alongside actual expenses.

These tools simplify cost tracking by ensuring all vendor and purchase transactions seamlessly flow into your project structure.

Development Recipes and R&D Items

For product development, you can utilize R&D items and development recipes to experiment and track costs without impacting your production environment. Both components replicate standard inventory functionality:

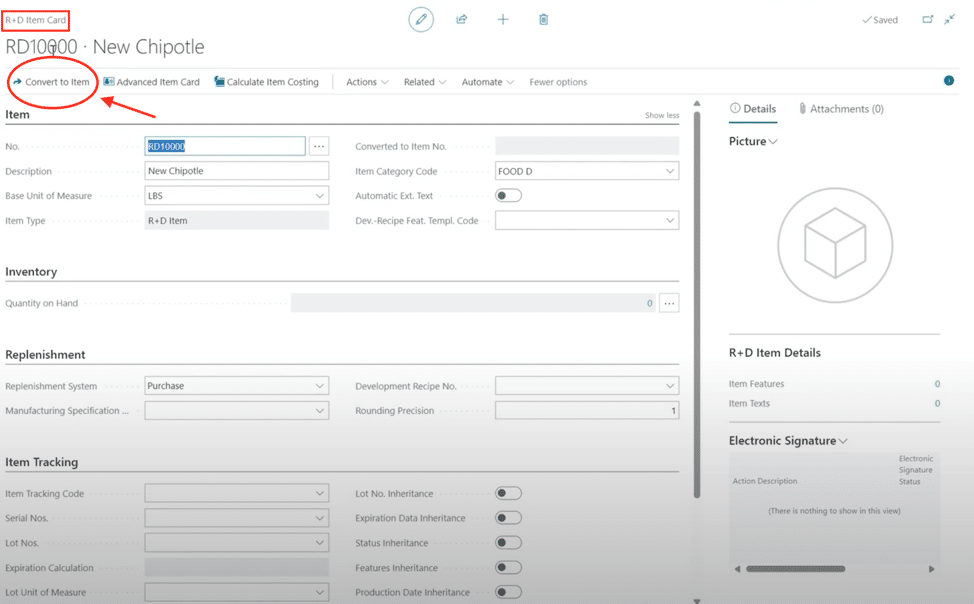

- R&D Items: Support features like lot tracking, serial numbers, and unit conversions. Once finalized, R&D items can be converted to regular items with a single click.

- Development Recipes: This allows you to create and tweak specifications for manufacturing processes, test routing changes, and compare recipe versions visually.

The key benefit is that these tools provide a “safe space” to develop and refine products while leveraging existing manufacturing workflows. Whether purchasing raw materials, inspecting quality, or creating production orders, processes remain consistent with your live environment—ensuring seamless transitions from R&D to production.

This integrated approach—combining flexible pricing, streamlined AP cost tracking, and structured R&D tools—helps manage project expenses efficiently while supporting innovation and development.

Item Costing and Cost Schedules

Business Central enhances cost management with dynamic cost schedules, enabling precise forecasting of inventory and production costs. Item costing integrates seamlessly, allowing businesses to calculate future costs for specific locations or manufacturing scenarios, providing detailed cost breakdowns and actionable insights.

With cost schedules linked to sales orders, teams can deliver accurate quotes based on projected costs, ensuring alignment between manufacturing expenses and pricing strategies. This integrated approach streamlines forecasting, pricing, and decision-making.

Flexible Cost Projections

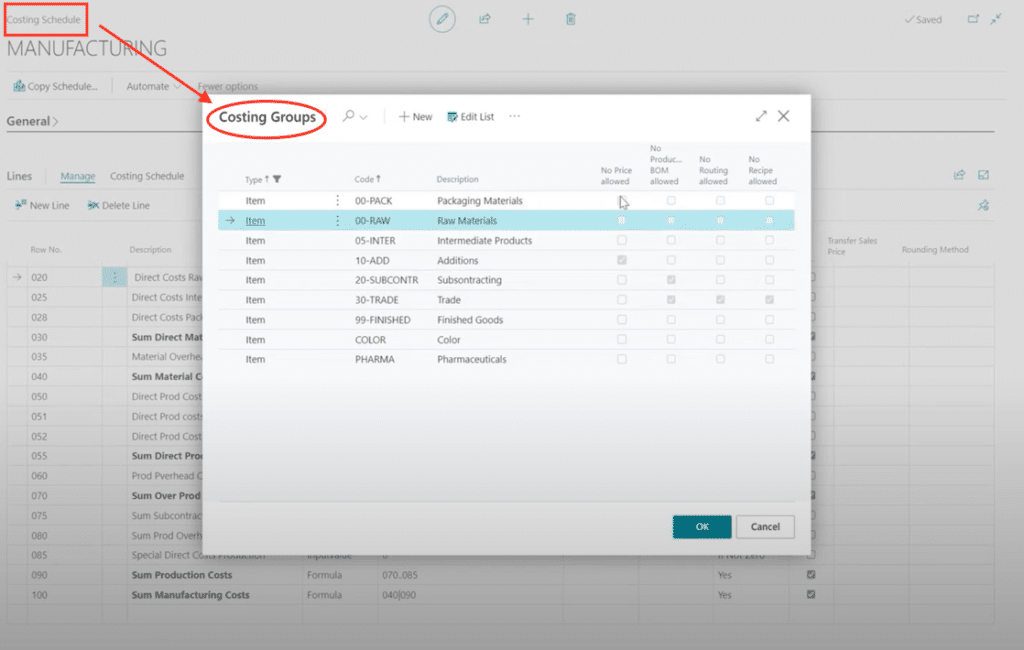

Item costing in Business Central gives users the ability to create cost schedules, offering a dynamic way to forecast and manage inventory costs. Cost schedules function similarly to financial reports, but specifically for inventory and production. By pulling in data from components such as raw material costs, work center rates, or machine center information, you can project cost changes over time. For example, if raw materials are expected to increase by 12% in six months, and packaging materials by only 2%, these projections can be configured easily. Similarly, work centers or departments, like production or QA, can have unique cost increases applied, allowing for granular control.

Once cost projections are configured, they can be applied to specific dates and inventory items. This enables businesses to calculate future costs with precision, helping anticipate manufacturing expenses or identify necessary price adjustments.

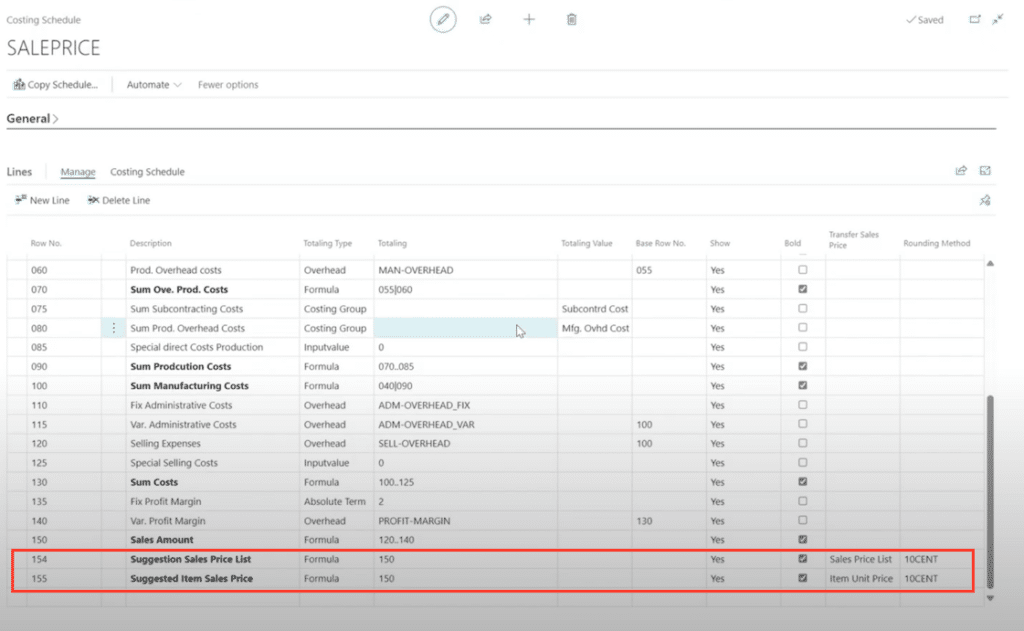

Driving Pricing with Cost Schedules

Cost schedules are not limited to forecasting costs; they can also inform sales price adjustments. Leveraging the same data—routings, bills of materials, and future cost factors—you can project sales prices based on target margins. This dual functionality ensures alignment between cost increases and pricing strategy.

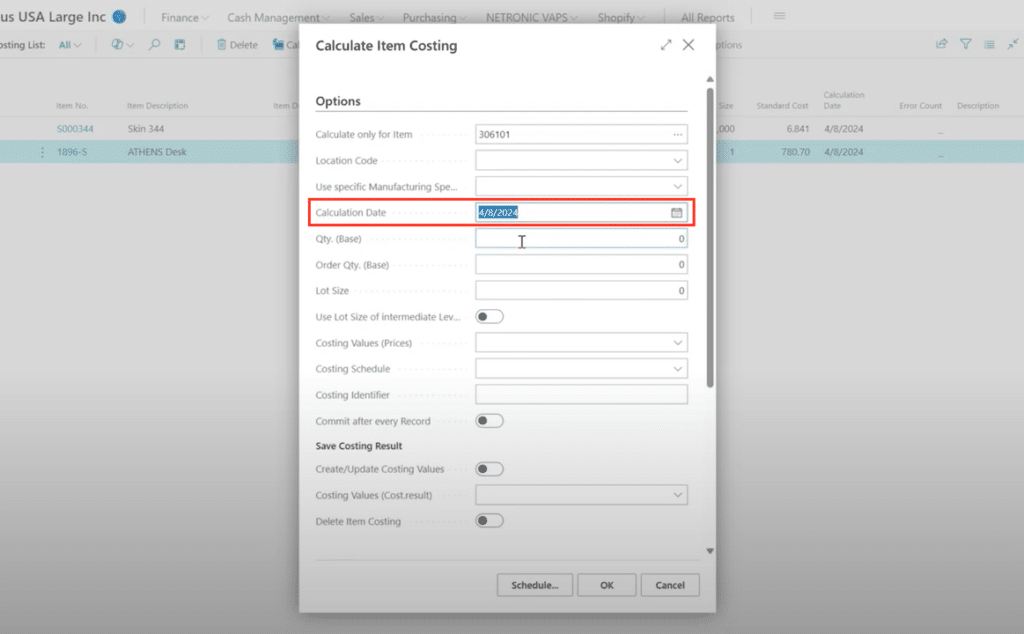

Item Cost Calculations in Action

The item costing feature brings everything together. You can calculate projected costs for a specific location, manufacturing specification, or future date. For example, if you anticipate building 10 units of an item six months from now, the system will apply all cost projections (raw materials, routing, and other factors) to estimate a future unit cost.

The results are clear and actionable: you’ll see the projected unit cost, cost breakdowns by raw materials, and routing details. These insights help assess cost efficiency and pricing for upcoming production runs.

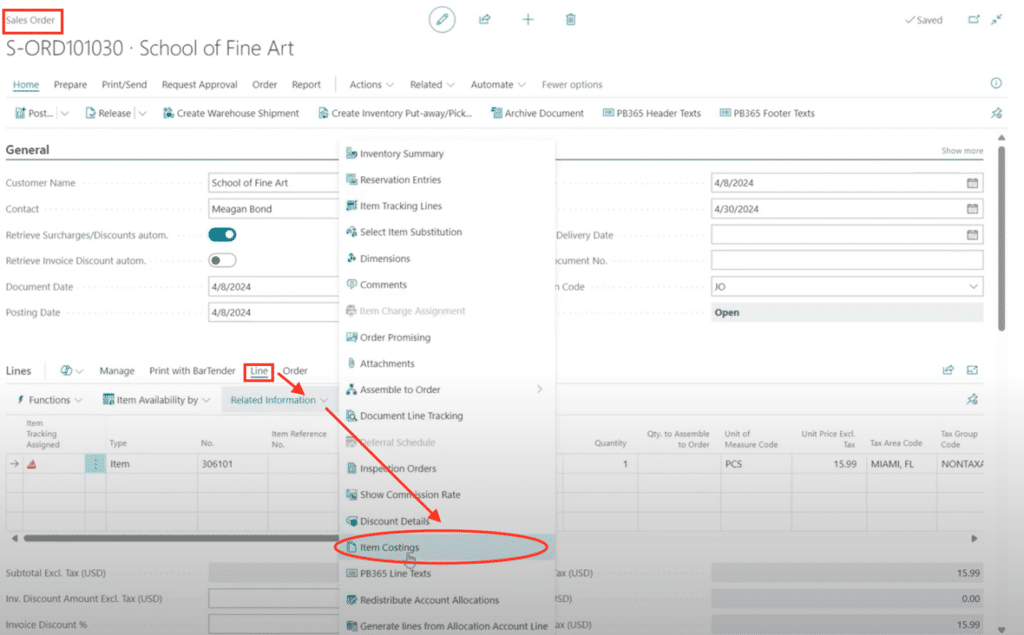

Cost Schedules on Sales Orders

Cost schedules integrate seamlessly with sales orders and sales quotes. If you create a sales quote for a future date, you can calculate and display item costing information directly from the sales order line. This allows sales teams to provide accurate pricing based on projected costs, ensuring quotes remain aligned with anticipated expenses.

By connecting cost schedules across manufacturing and sales, Business Central simplifies cost management, enhances forecasting accuracy, and supports strategic decision-making.

Use Dynamics 365 Business Central and YAVEON ProBatch to Optimize Your Research and Development Project Management Process

Business Central project and costing capabilities provide a comprehensive framework for managing financial transactions, budgeting, and billing scenarios, while also supporting iterative development and cost planning in manufacturing. The project module streamlines processes like AP transactions, GL budgeting, and progress billings, ensuring flexibility for both fixed-fee and time-and-material needs. Meanwhile, the R&D item and development recipe allows for iterative adjustments, offering a “playground” to refine manufacturing specifications and production outcomes.

Talk to Stoneridge Today to Learn More

If you need help implementing, optimizing, or supporting manufacturing solutions, get in touch with the experts at Stoneridge Software today. We have a team of Business Central experts who know the ins and outs of that ERP solution and work very closely with YAVEON to deliver innovative and actionable technology solutions to manufacturers.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.