Using Dynamics 365 Business Central and YAVEON ProBatch to Optimize Your Batch Manufacturing Process: Manufacturing Execution

Microsoft Dynamics 365 Business Central has a robust set of functionalities and immense flexibility. With this solution, you can manage your core financials and streamline industry-specific operations. When it comes to manufacturing, this software handles everything from lot management and compliance to quality assurance and manufacturing execution.

In this walkthrough, we’ll explore how Microsoft Dynamics 365 Business Central, together with YAVEON ProBatch, can help your firm with manufacturing execution.

YAVEON ProBatch Integration with Dynamics 365 Business Central

Our batch industry solutions are powered by YAVEON ProBatch, running on Microsoft Dynamics 365 Business Central. This application fully integrates with Business Central and is designed specifically for use by companies in the pharmaceuticals, biotechnology, cosmetics, food, medical technology, and chemical industries.

You can use our batch manufacturing solution to assist with every stage of the manufacturing process. For this walkthrough, we’re going to focus on the following topics related to manufacturing execution:

- Production planning

- Barcode scanning

- Visual scheduling

- Labor and machine time capture

- Scale (weighing orders)

- Dispensing

Production Planning

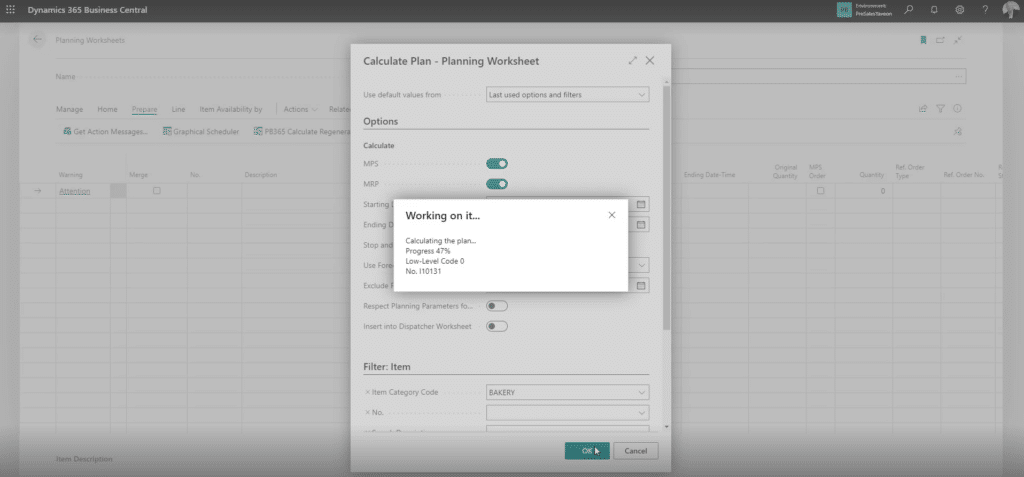

Let’s start with production planning. We’re going to calculate the planning worksheet. To do this, navigate to Planning Worksheets > Prepare > PB365 Calculate Regenerative Plan from within your Microsoft Dynamics 365 environment.

When you select “Calculate Regenerative Plan,” a pop-up will appear. Here you can look at your production schedule and material requirements. In this example, we'll be looking at a specific subset of items. When you click “OK,” the planning worksheet will net supply and demand for you.

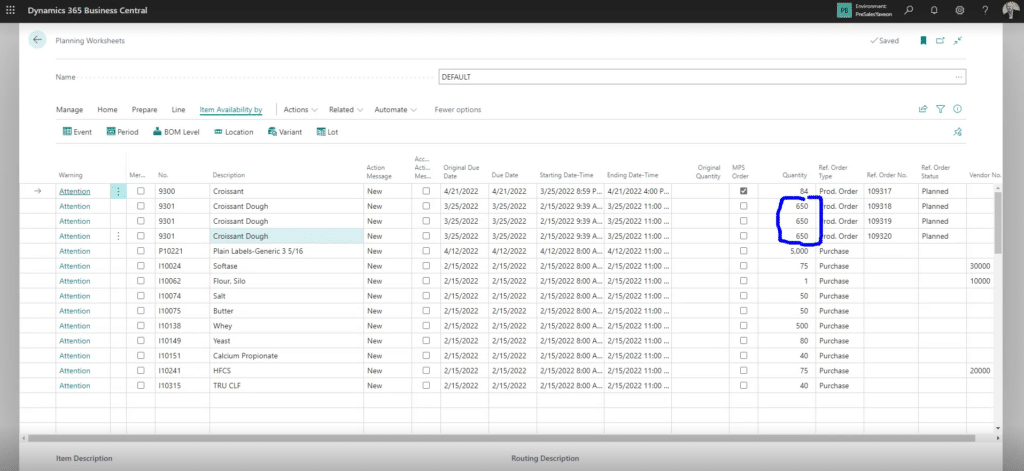

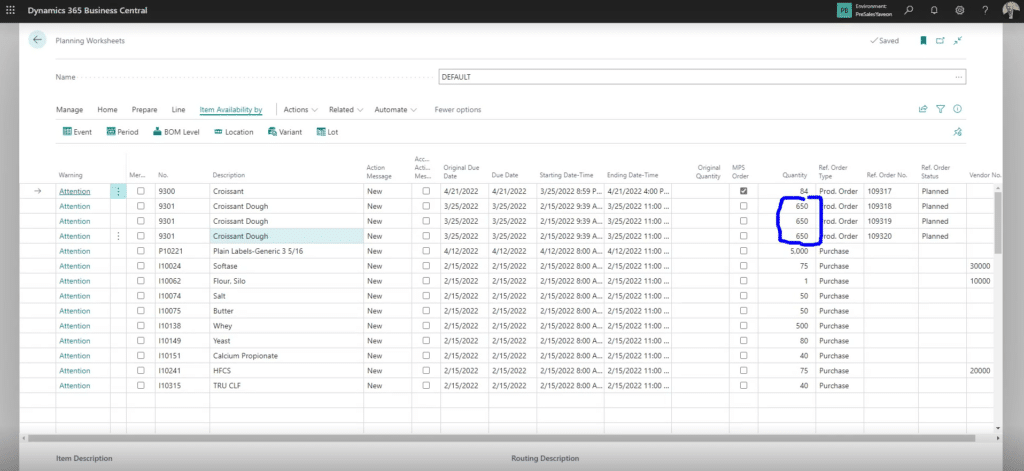

It does this by looking at the total supply in the system and total demand in the system, and then it suggests production orders, assembly orders, transfers, or purchases to net — or accommodate — your total demand requirements in the system. Essentially, this will look at the demand that’s going to be calculated or the demand that’s recognized in the system.

In this example, you’ll notice that there are planning parameters we’ve set up for items. If you’re looking at minimum batch sizes, you’ll notice our croissant dough is set to a batch size of 650 lbs, and there’s a requirement for something greater than 650 lbs. Because of this, it creates three individual batches to accommodate the total demand.

With this solution, we can order specific numbers. Calculations for batch sizes and lot accumulation periods are available to us, too.

Creating a Production Order

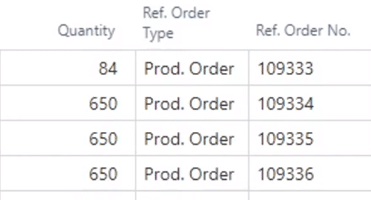

Let’s carry out the action message on four production orders so that we can look at some manufacturing concepts. To do this, you can select “Accept Action Message” beside your chosen production orders and navigate to Home > Carry Out Action Messages. We’ll create these as firm-planned orders, as this will allow us to create the assembly orders and purchase orders, and documents needed by our shop for execution.

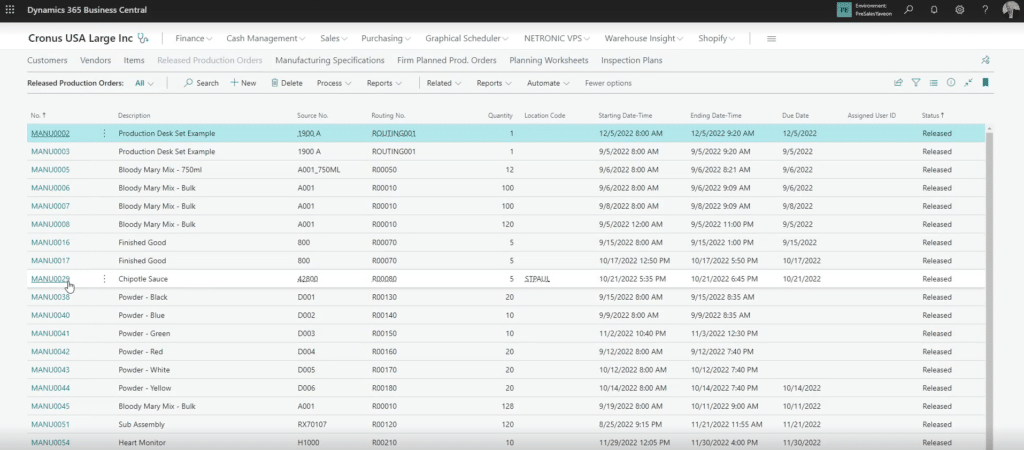

When you’ve carried out these action messages, navigate to your Released Production Orders. We’ll use a production order to explore some manufacturing execution functionalities.

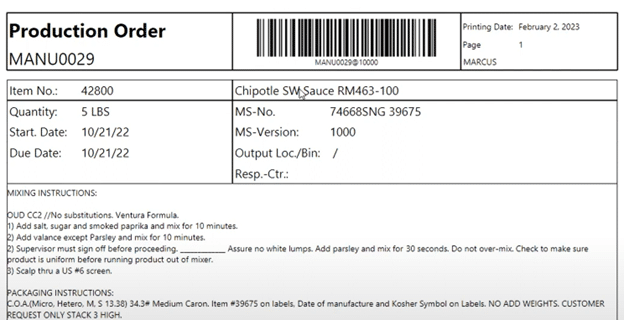

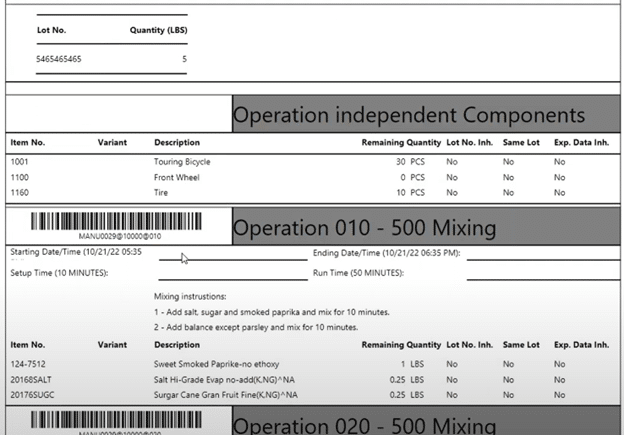

On the production order itself, we can look at the routing and the components that are on this production order. If needed, we can make changes or adjustments, substitute items, and so forth. For this walkthrough, though, we’ll focus on printing a production order so that you can see the type of output that we have available to us. This might be a job ticket that’s going to go to the shop floor. It has your production information on it, of course, but more importantly, it has barcodes that set you up for scanning capabilities.

Barcode Scanning

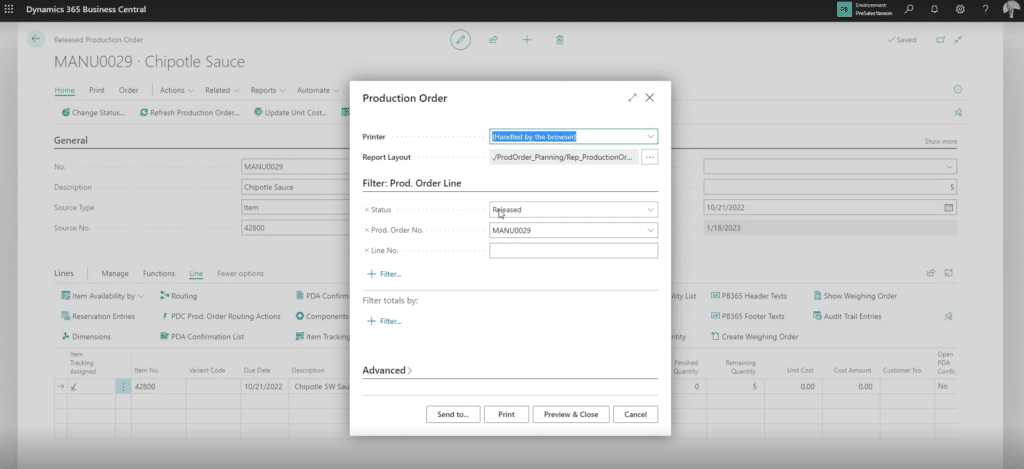

To do this within the individual production order, you simply navigate to Actions > Print > Production Order. When the popup message appears, you can preview your order, print it, or share the report.

Out of the box, barcodes exist in the system for data capture and for scanning in the system. You can embed work instructions on your production orders if you so choose. Here, you’ll notice that our operations are also set up with barcode scanning so we can capture this data.

Visual Scheduling

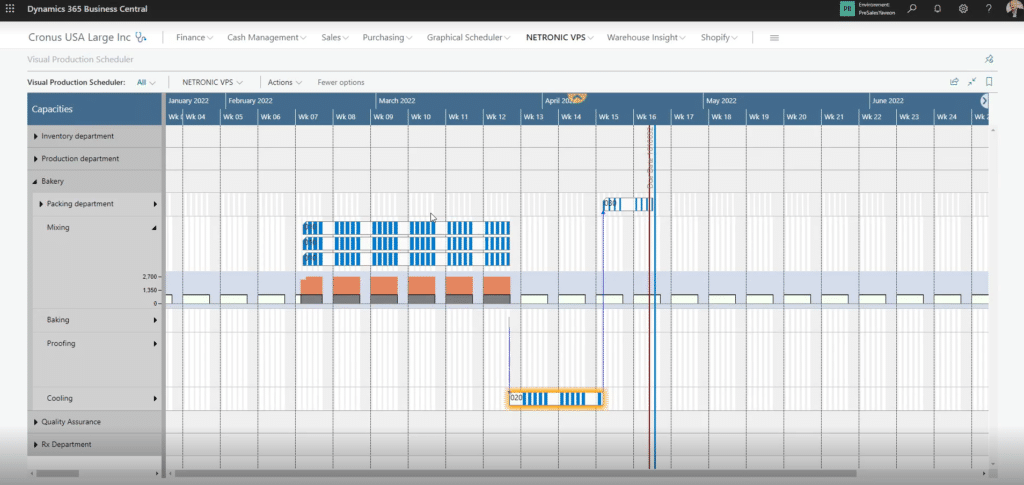

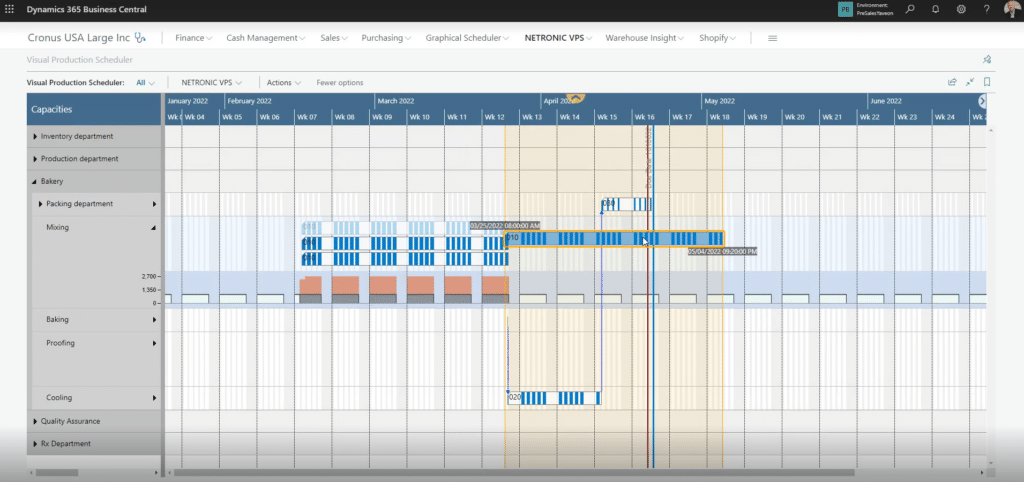

Let’s take a look at the visual scheduling options available to you. To do this, you can navigate to NETRONIC VPS > Visual Production Scheduler. This is one option that allows you to visualize what’s currently on your production floor. Using this feature, you’re able to look at subsets of machine centers, work centers, different dates, plans, firm plans, and released production orders.

In the example above, you can see that in our mixing department, we have the three levels of croissants, as well as some dough that’s being made.

If you need to reschedule, alter the existing timeline, or move a particular production order around the shop floor, you can simply drag and drop the affected elements within the Visual Production Scheduler and the system automatically updates accordingly.

Labor and Machine Time Capture

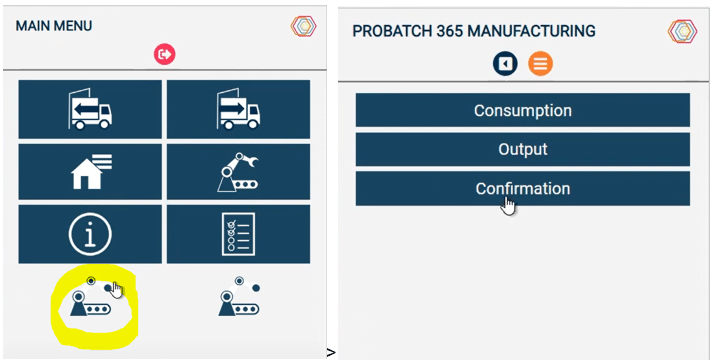

We’ve already printed our production order, so let’s pull up our scanning application. Keep in mind that this app can be used on any device that’s running a browser.

These icons relate to different warehouse operations, but for this walkthrough, we’re going to click into the production capabilities. You have three options here: Confirmation, Consumption, and Output.

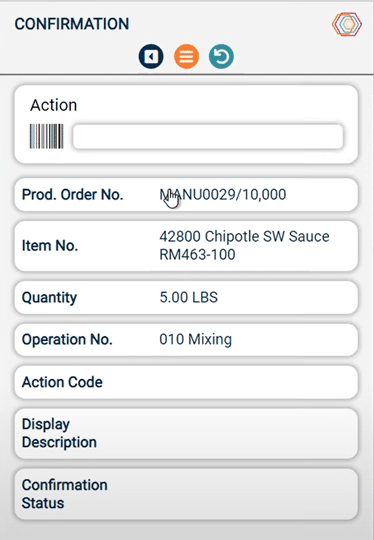

The Confirmation feature allows you to scan a particular operation on our ticket so that you can select the operation you’re running. When you scan the Action code, it helps you capture and track time spent on a particular step in the production order. It is, essentially, a clocking-in and clocking-out feature.

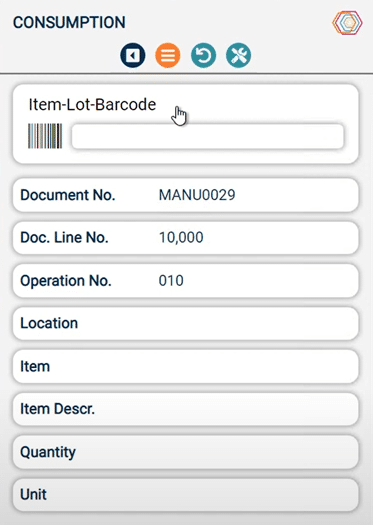

This application also lets you record consumption, thanks to its ability to scan a particular production line. This feature allows you to scan the item lot barcode located directly on the product, package, or tote — whatever you’re “consuming” into the production process. This will be part of the production order on the manufacturing specification, and you can record the quantity you’re consuming onto the product.

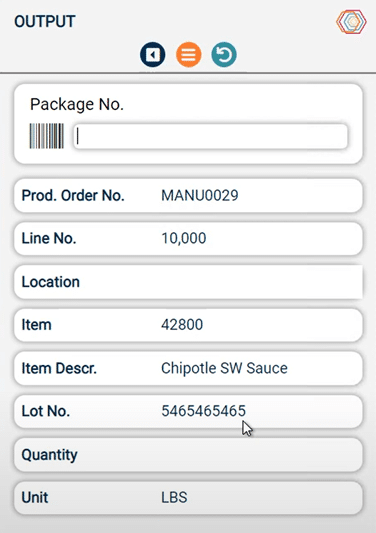

The Output feature is quite similar to Consumption. You can record the production order itself to know which order you’re completing. If you require package tracking or load carrier capabilities, the app will prompt you to input that information in the Package line item. Your lot number can be preassigned or you can capture that information during this step, as well.

Scale: Weighing Orders

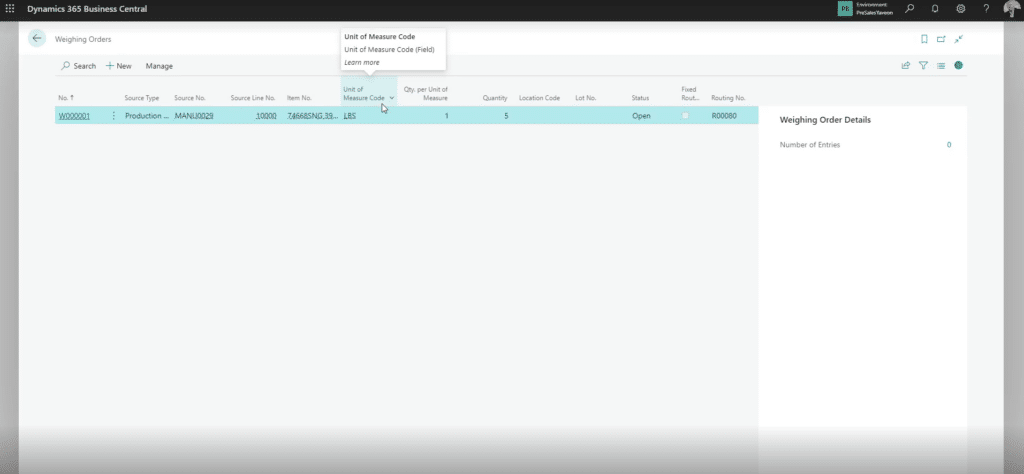

Some organizations need the ability to use a scale to weigh out products. We have a scale integration to assist with this, and it’s tied into a feature called “Weighing Order.” The Weighing Order allows you to designate — on the raw material itself — that the raw material is dispensed using a scale. This allows you then to weigh the product using an integrated scale to record the quantity that you’re consuming.

We also can perform provisional picking. This would, for example, allow you to move an entire tote to the manufacturing area, dispense the product that you would need out of that tote, barrel, or package, and then put it back. So it’s a provisional pick-and-put-away function of the entire container, and this feature helps facilitate those processes.

Dispensing

The other functionality that is sometimes needed with batch manufacturing is the ability to perform the filling or dispensing of the product.

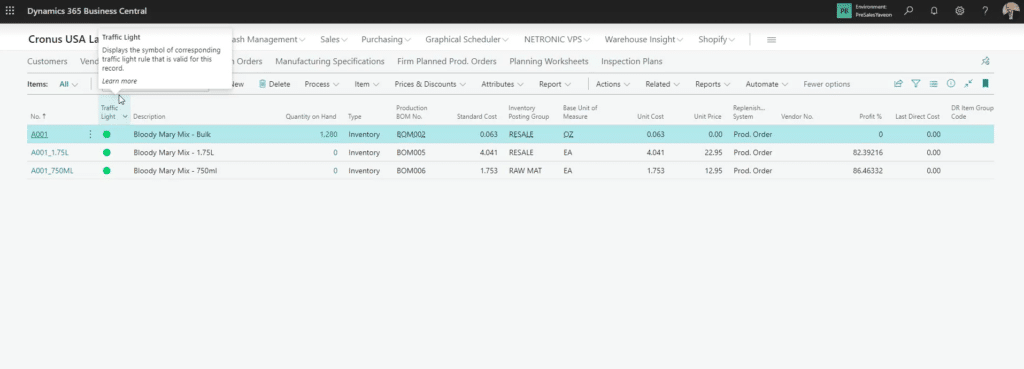

In this example, we have a product that we’re making in bulk. You’ll notice that we have two package sizes into which the specific product can be placed. The system allows you to create a base formula — in this case your bulk product. You have a recipe for the bulk product, so you manufacture the product in bulk and then can either dispense it (as a secondary production function) into the containers that you want during that production process, or you can store the bulk product and do what’s called a “decanting order.” If you choose to run a decanting order, this would essentially fill the container sizes as needed to fulfill your sales demand.

The key element here is that these items are tied together so that the relationship is understood between the bulk item and the filling items, and you have a consistent recipe that’s available as well. Instead of having to maintain the recipe for all three products, you only maintain it for one.

Do you want to learn more?

Dynamics 365 and YAVEON ProBatch can help you address, improve, and optimize a wide variety of different business processes. Please get in touch with a Stoneridge Software expert for more information!

Are videos more your speed? Head to our YouTube page or click on the video below to see a demonstration about how to use these great solutions.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.