Planning Items and Formulas in Dynamics 365 Finance and Operations: Configuration Requirements

Knowing how to properly deploy Planning Items and Formulas in Dynamics 365 Finance and Operations is essential to making sure they can fully optimize your manufacturing process.

In the first blog in this series, we identified what these functionalities are and how they can help you streamline your manufacturing processes.

In this part, we will take a look at the configuration requirements you need to have in place before using them and give you step-by-step instructions to make sure they are set up for your organization’s needs and benefits.

In part three, we will shift the focus to provide you with real-world examples of how process manufacturers can use this functionality.

Four Steps on Configuring Planning Items and Formulas in Dynamics 365 Finance and Operations

By following these steps, you can tailor Planning Items and Formulas to help you with specific processes:

1. Determine which production processes will require a planning item and formula

Go into your system and find out which processes could be streamlined from a planning item and formula.

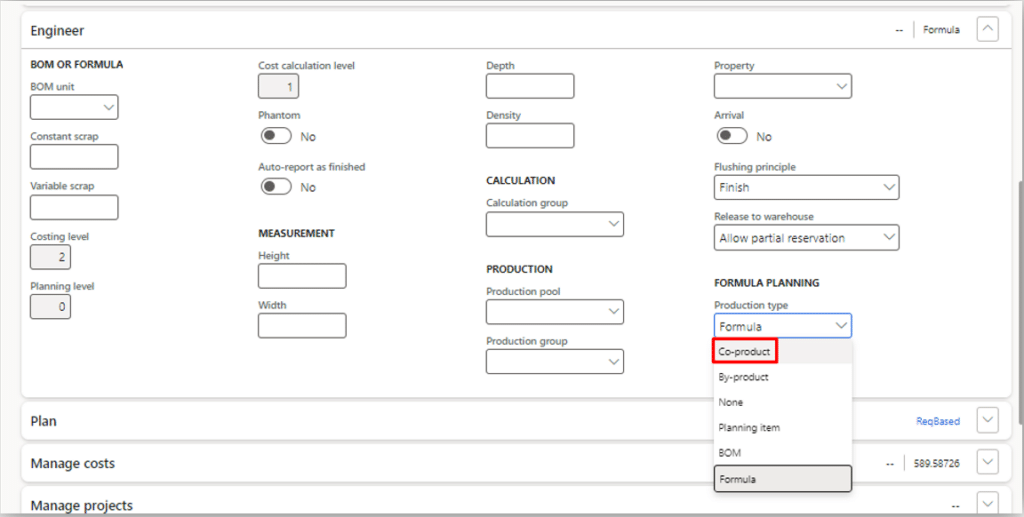

2. Change current "primary" items to be co-products using the production type setting in released product details

This can be difficult to do with existing items as they may have already been used in production. If that’s the case a new item may be needed.

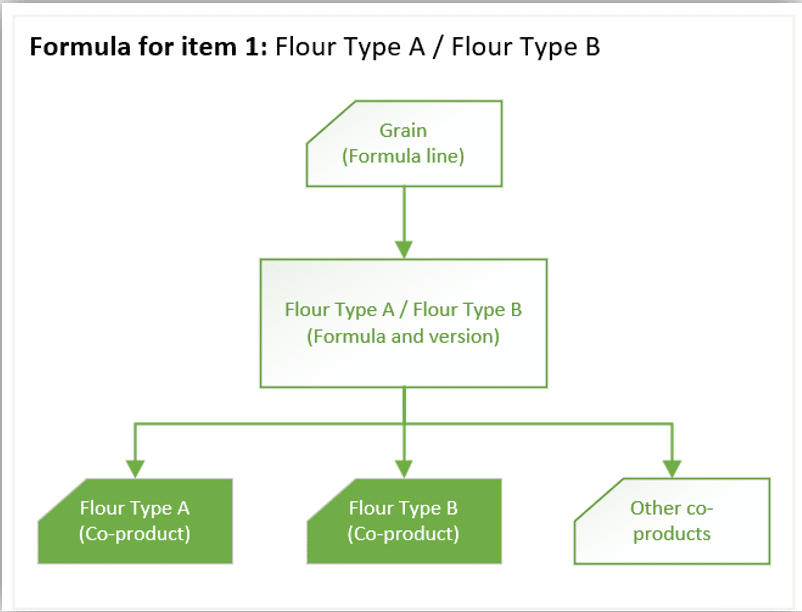

Once all “primary” items are set as co-products, planning items will need to be set up to facilitate each of those production processes. In Part 1 of this blog, I provided a real-world example from the flour milling industry. I will continue with that example throughout the configuration steps.

In the following example, these assumptions exist:

- One type of grain will be consumed (This will be our formula line in each planning formula)

- Two types of flour can be produced:

- Type A: Can only be produced as a split run with Type B flour, however, the output ratio may be adjusted as needed.

- Type B: Can either be produced in a split run with Type A or can be produced independently.

- Additional co-products exist in every production run

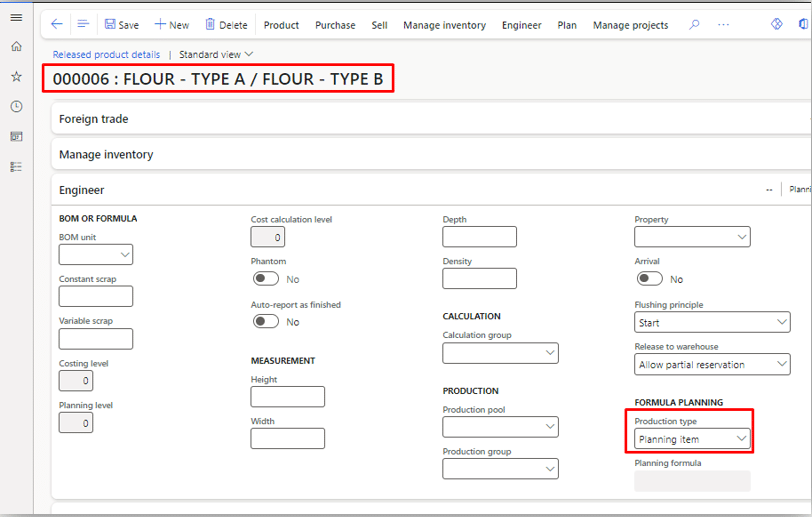

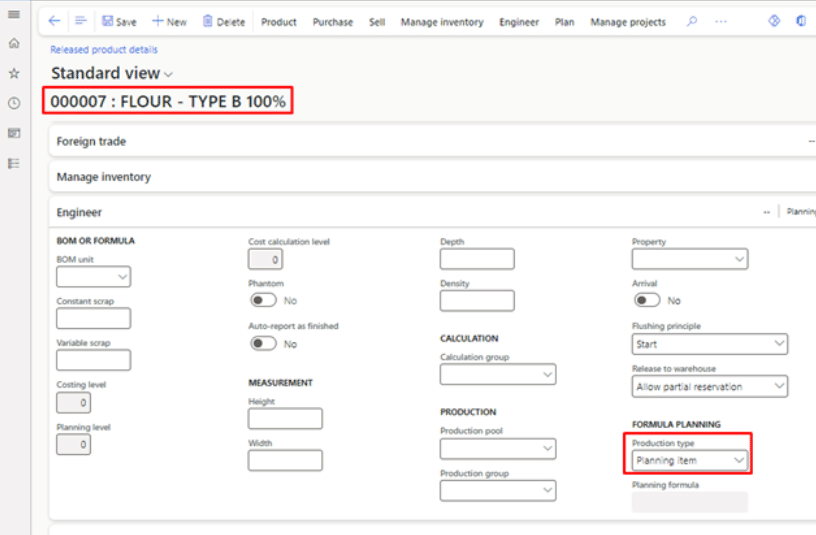

3. Set up two planning items

The first item in this example is Flour Type A/Flour Type B. The forward slash provides an intuitive way to communicate my split run scenario to production staff.

For our second item, we will go with Flour Type B 100%. The 100% provides an indication that this is not a split. The original item number cannot be used as the original item still exists, now as a co-product.

You might be asking why this planning item is required. Since the original item, Type B, is now a co-product it cannot be associated with a formula. Another planning item and formula are required to produce it. Another option would be to use the Type A / Type B item and formula and adjust the co-product quantities in the batch order to be 0%/100% instead of 50%/50% for accurate planning. However, production staff will have a harder time knowing what’s expected if done this way.

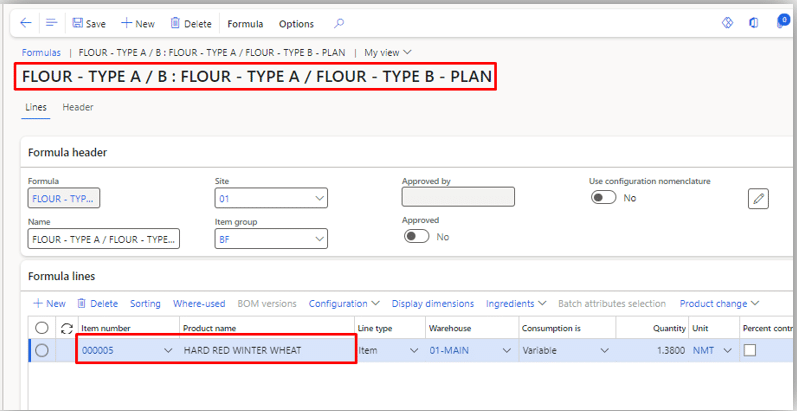

4. Create a formula and formula version for each planning item

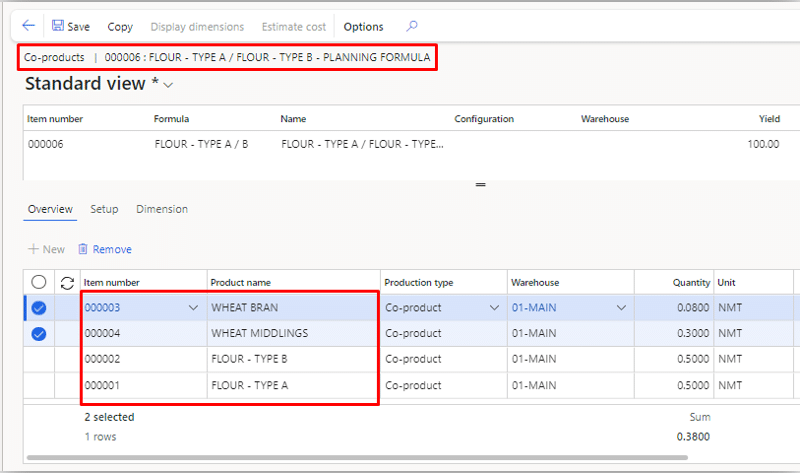

In each formula, the formula line is consistent, but the formula co-products will vary based on the expected output. Below are some examples:

Formula: Flour Type A/Flour Type B:

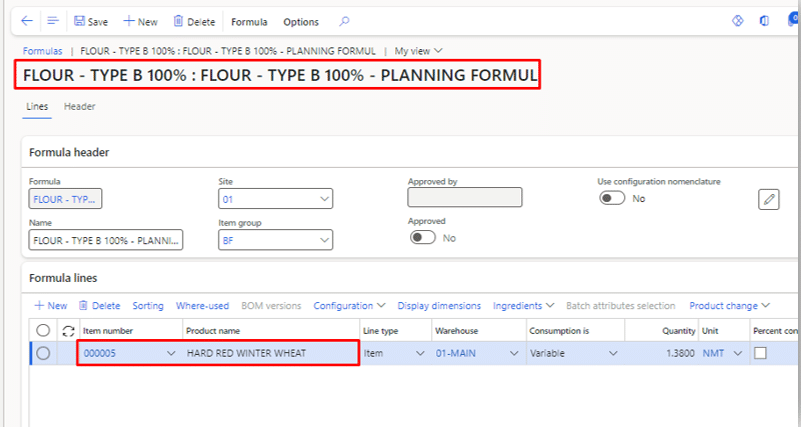

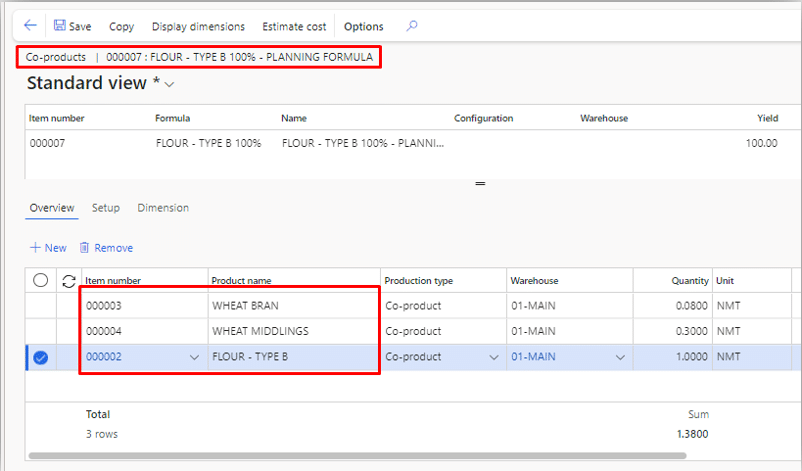

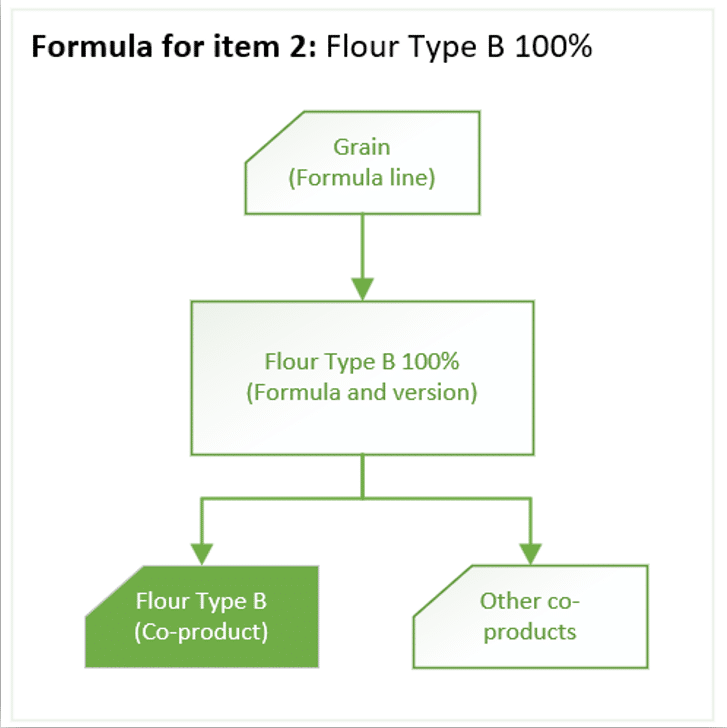

Flour Type B 100%:

The last thing you want to configure is required if you want master planning to recommend planned batch orders for one of your planning items anytime a co-product must be produced.

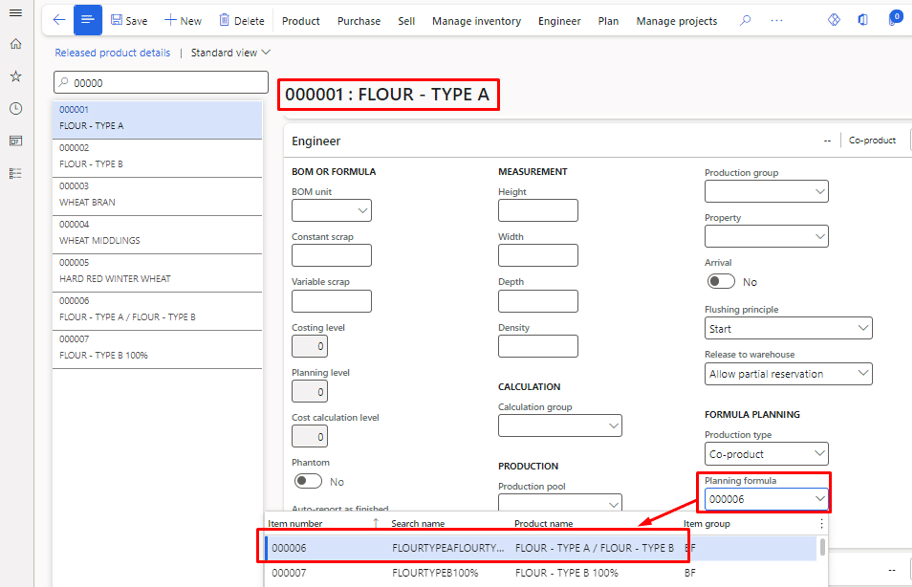

The last configuration requirement is necessary if we want master planning to recommend planned batch orders for one of our planning items anytime a co-product must be produced. In this example, it’s assumed that Flour Type A is more common, so the split run of Flour Type A and Flour Type B is used. Considering this assumption, the Flour Type A released product is updated by setting the Planning formula to the Flour Type A / Flour Type B formula.

After that, your configuration is complete. If additional split runs come up you can follow the same process to set them up. If you need to change the planning formula on the co-products you can use the drive to standard process.

Want to Learn More Techniques to Optimize Dynamics 365 Finance and Operations?

Reach out to our team! Whether you are interested in planning items and formulas or looking for additional ways to optimize your environment and streamline work, we can help.

Click here to see part one of this series.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.