Bill of Material Features in Microsoft Dynamics AX 2012

A Bill of Materials (BOM) is conventionally described as the list of components needed to make an item. This post examines some of the basic ways of implementing BOM's in Microsoft Dynamics AX 2012 (DAX).

Each component that is required to make a product in DAX is represented by a BOM line. Every item that must be accounted for in costing or in inventory should be included on the BOM for an item. Most companies use items in their manufacturing processes which are not valuable enough to be worth noting and tracking on a BOM, such as different greases, shop supplies, etc. But anything which needs to be brought to the manufacturing floor specifically for an item should be on the BOM, for the BOM controls the items which are picked to support production orders.

Note that in AX, products are given a type when they are created. That type can be an item or a service. Both product types can be included in a Bill of Materials. Inclusion of services on a BOM allows for planning and costing of the services.

Another advanced feature of BOM setup in AX is that a BOM can be declared in multiple versions and attached to multiple end products:

Version control allows for changes to an item, and enables different configurations of a BOM depending upon different circumstances. Components can be phased out and replaced using version control.

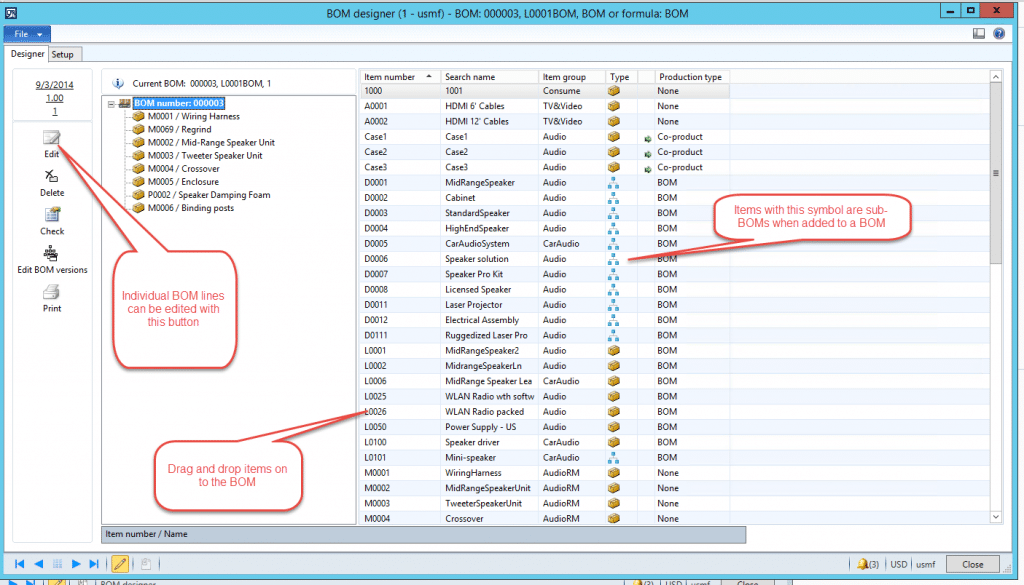

Once a BOM has been created, it can be viewed and maintained using the BOM Designer:

The designer provides graphical drag and drop capability for editing BOMs as well as calling the detail edit form for BOM lines. The symbols in the Type column designate Items, sub-BOMs, and Services (not shown).

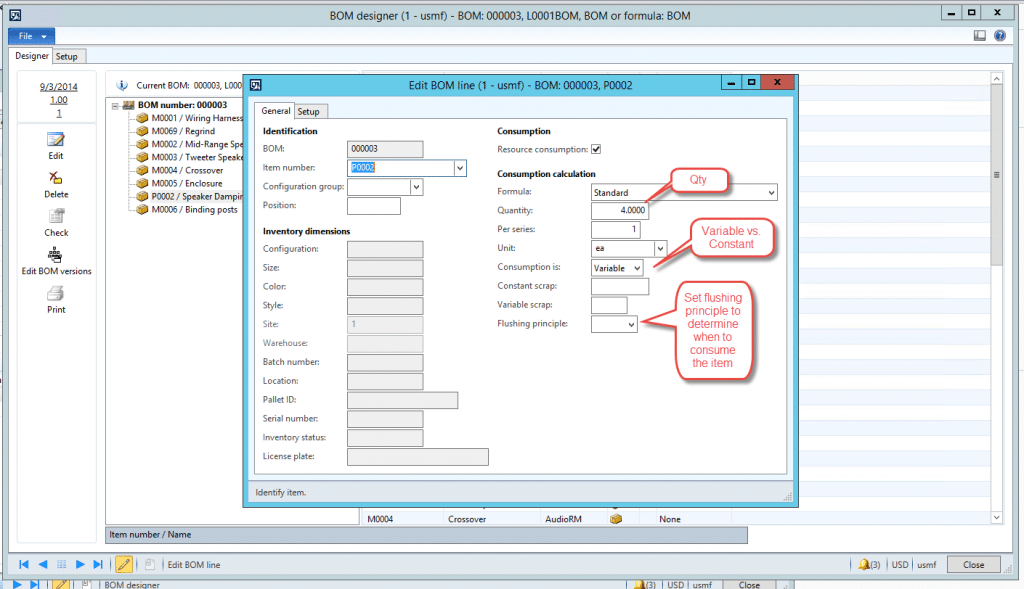

As each BOM line is added, it should be edited to provide the correct BOM Quantity:

There are other advanced features in Dynamics AX 2012 BOMs:

- - Quantity Dependent BOM’s: different order quantities of the end product can be set up to be made using different BOM versions.

- - BOMs and Routes can be set up in different levels of the BOM to plan and produce sub-BOMs at different sites.

- - Phantom BOMs can be set up: Phantoms are not schedule or necessarily stocked in inventory, but can be used to calculate materials requirements and to simplify BOM setup and maintenance.

Future posts will dig deeper into setting up and using BOMs in Dynamics AX.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.