Production Order Backflushing Using a Warehouse Management Enabled Warehouse in Dynamics AX

There can be scenarios when you are using a Warehouse Management Enabled Warehouse and would like to backflush your raw materials for production. When using a Warehouse Management Enabled Warehouse, traditional raw material back flushing will not work.

Backflush Raw Material Using Warehouse Management

In the steps below I'll show the setup required to backflush raw material using Warehouse Management in Dynamics AX . For this scenario, I am using Dynamics AX 2012 R3 CU12.

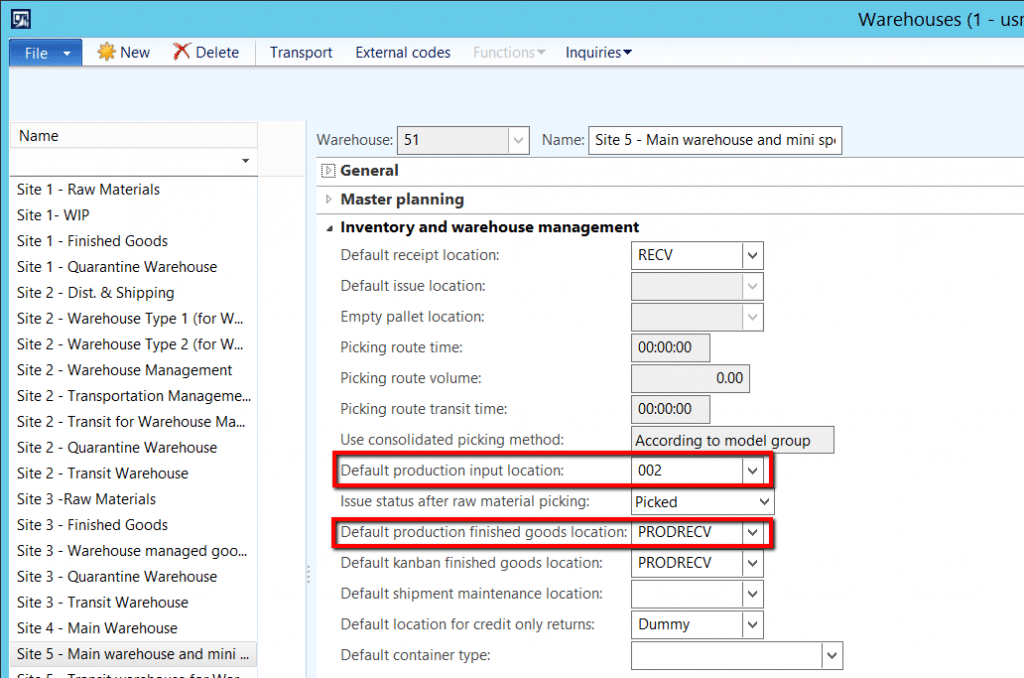

1. Warehouse Setup

- Warehouse 51 is a Warehouse Management Enabled Warehouse.

- Specify a default production input location and a default production finished goods location.

- Location 002 is a non-license plate controlled location.

- Location PRODRECV is a license plate controlled location.

Note: Default input location and default finished goods location can also be specified in the resource group.

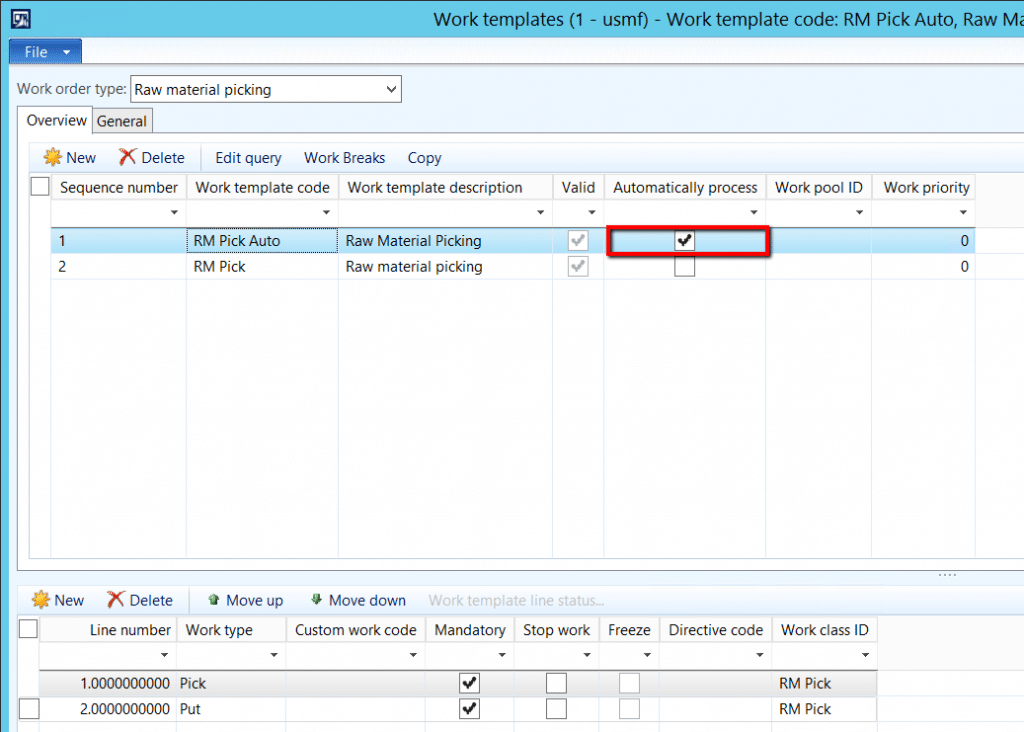

2. Work Template Setup

Create a work template for raw material picking. My work template is a simple pick and put work transaction set to automatically process.

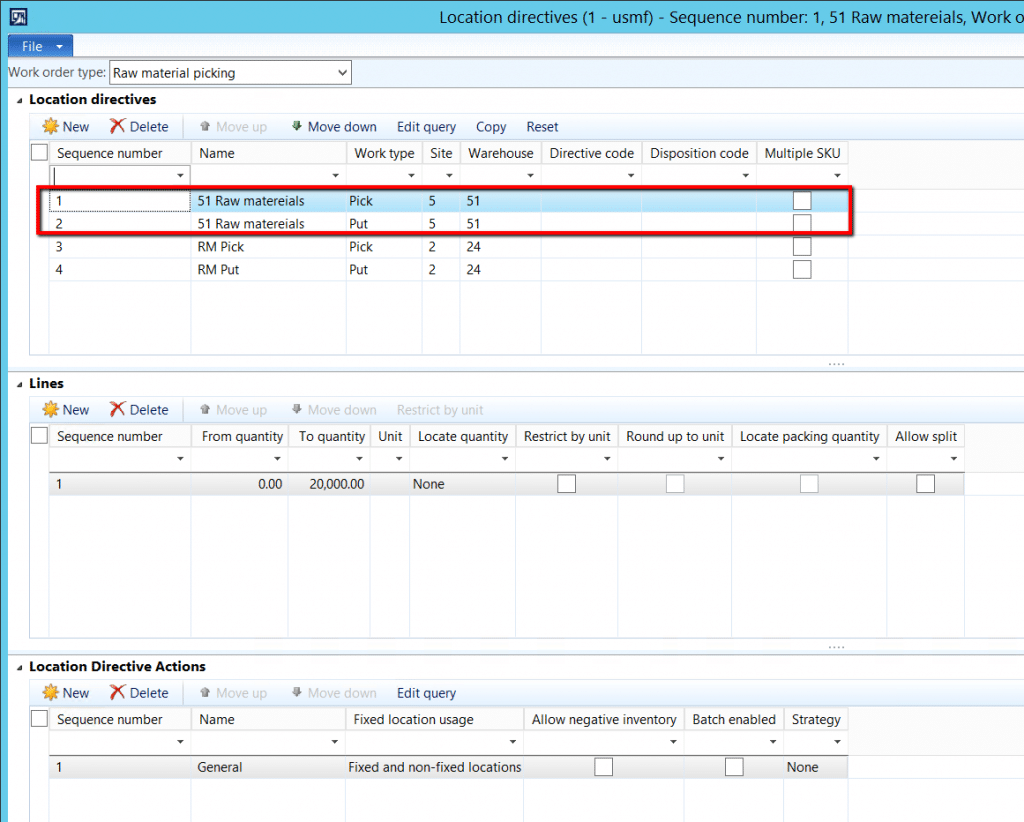

3. Location Directive Setup

Create a location directive for Raw Material Picking.

- Pick location directive is set to pick from a non-license plate controlled production stage location.

- Put location directive is set to put inventory into location 002, which is my default production input location and is specified on the warehouse.

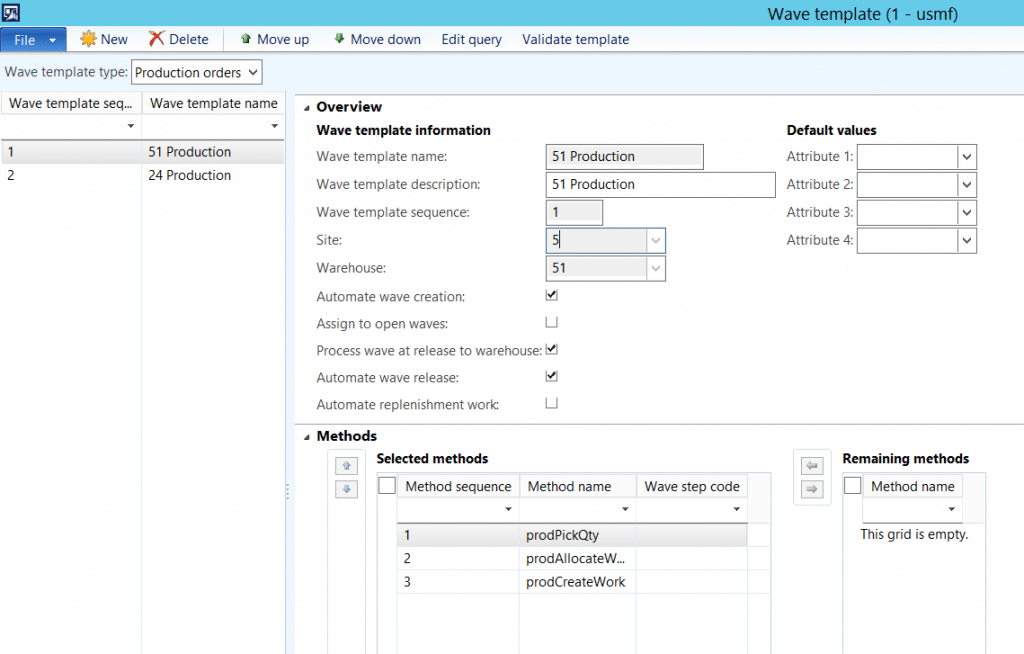

4. Production Wave Template Setup

A wave template is created for Warehouse 51. Wave is set to automate wave creation, process wave at release to warehouse, and automate wave release.

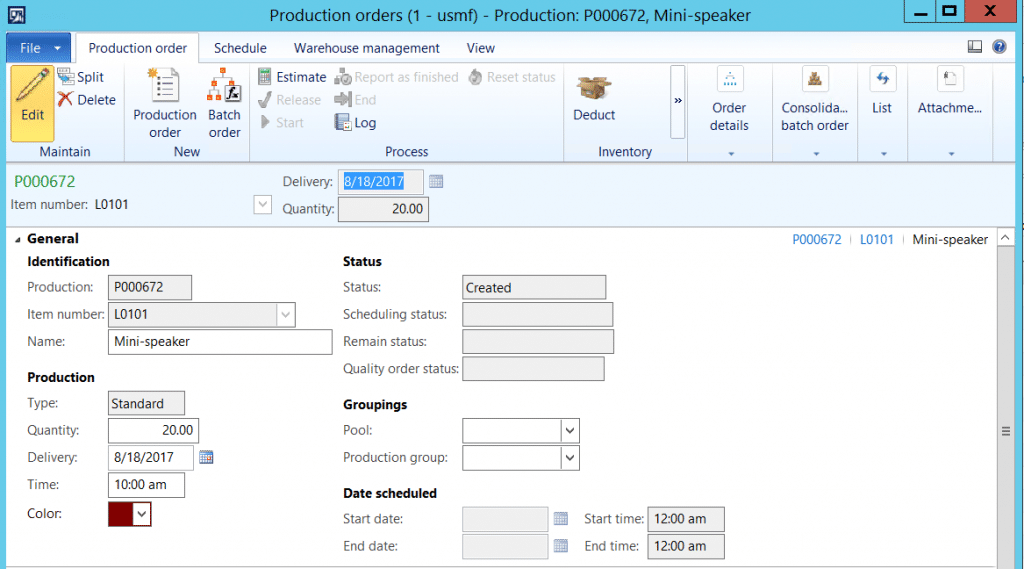

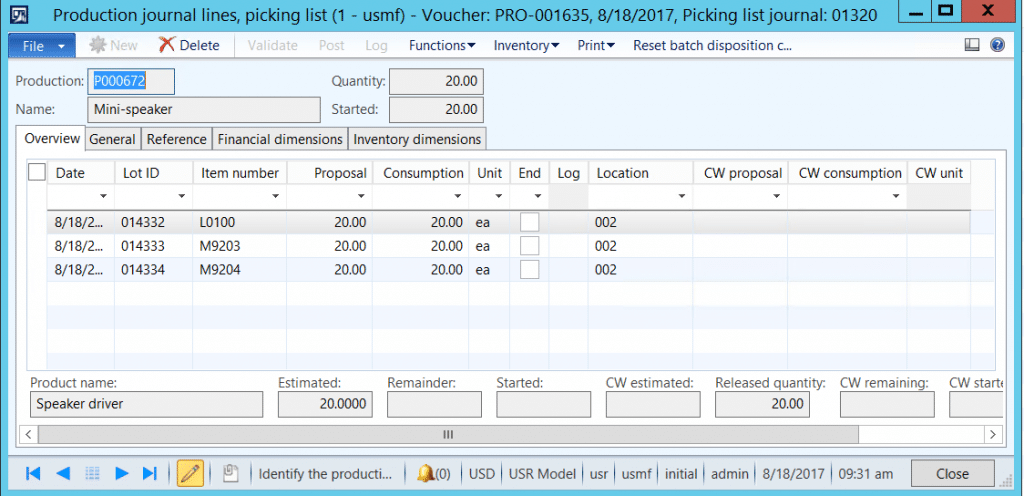

5. Production Order

I created a Production Order for 20 units of L0101.

Note: Production orders parameters are set to reserve inventory at estimation.

Production order is estimated and inventory is automatically reserved.

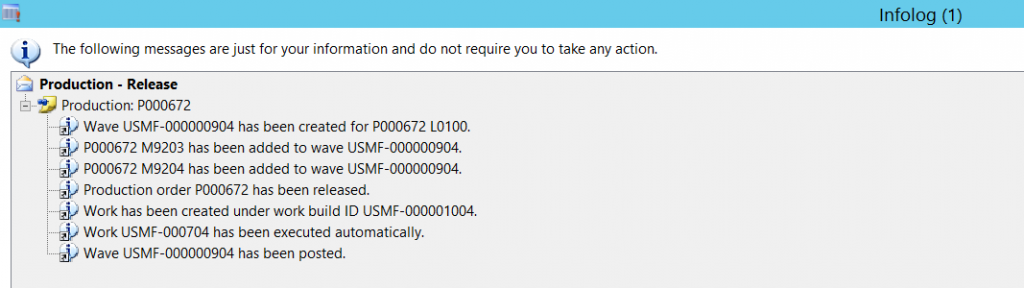

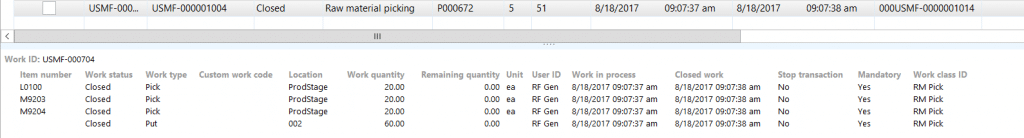

6. Production Order Release

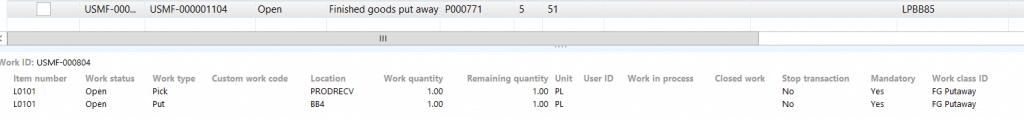

When the production order is released, AX automatically creates the wave, processes the wave, creates work and completes the work.

Below is the completed work transactions. My raw materials were picked from the non-license plate controlled ProdStage location and put to the default input location 002.

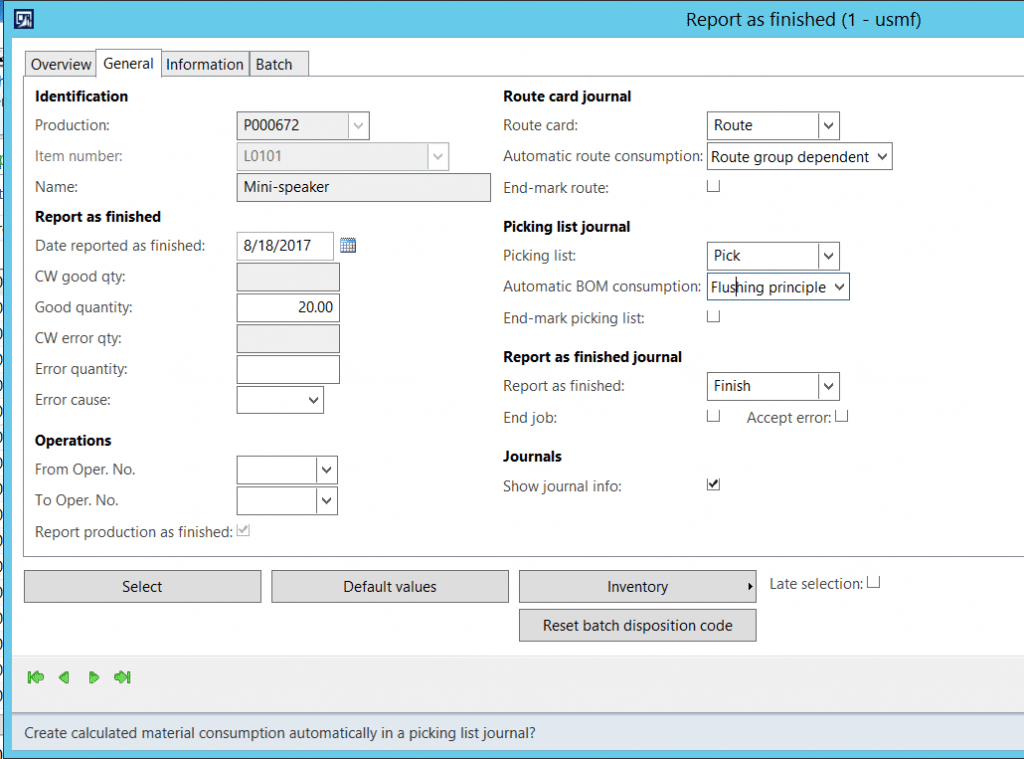

7. Report as finished

Note: Raw Materials are set to backflush at Finish.

Note: Report as finished picking list journal is set to flushing principle.

When the report as finished journal is posted, a picking list is created and posted. Inventory is consumed out of the default issue location 002.

The report as finished posting also has created finished goods put away work. The pick transaction is from the default production finished goods location specified on the warehouse.

This is a great solution for raw materials that you do not want workers physically performing production raw material picking work.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.