Streamlining Quality Assurance in Batch Manufacturing with Dynamics 365 Business Central and YAVEON ProBatch

Batch Manufacturing exists in a sector where quality assurance is non-negotiable, and the margin for error is very slim.

Industries like biotech, chemical, cosmetics, food manufacturing, medical devices, and pharmaceuticals need to have an unwavering commitment to quality at every step.

Dynamics 365 Business Central and YAVEON ProBatch for Batch Manufacturing

Achieving this high standard is made possible through the strategic use of software solutions like Microsoft Dynamics 365 Business Central, enhanced by YAVEON Pro Batch. This powerful combination delivers a comprehensive financial and manufacturing solution, ensuring quality control is never compromised.

Business operations hinge on flawless inventory management and inspection procedures. Precision, accuracy, and meticulous attention to detail are vital in this process. For example, the feature to record visual value revolutionizes the inspection process. It enables operators to document the visual inspection of a product, such as a container, marking the completion of that inspection phase. This proves invaluable in situations where visual inspection plays a pivotal role in product validation.

The Importance of Quality Assurance and Inspection Plans in Batch Manufacturing

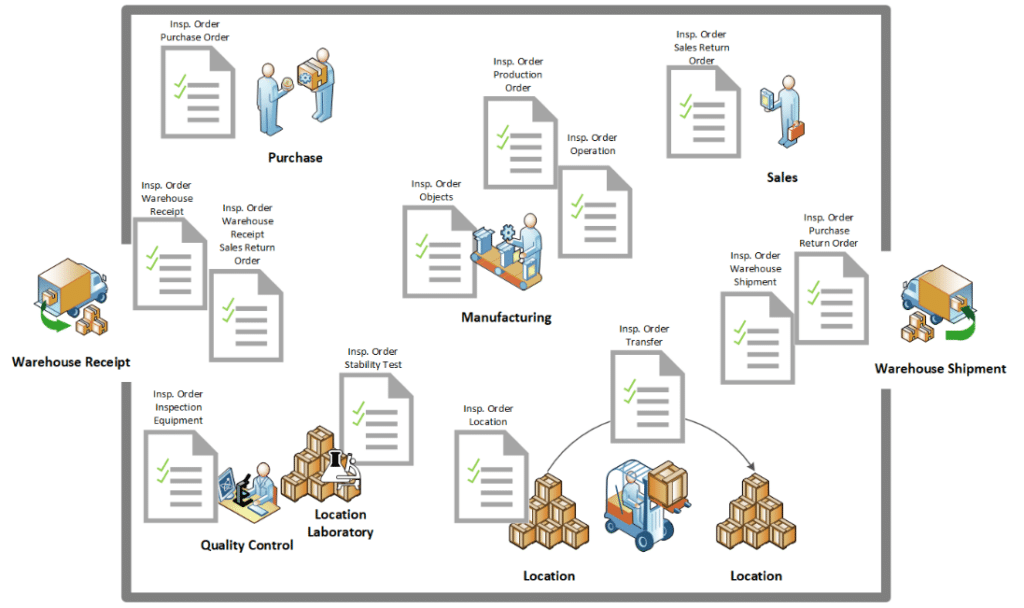

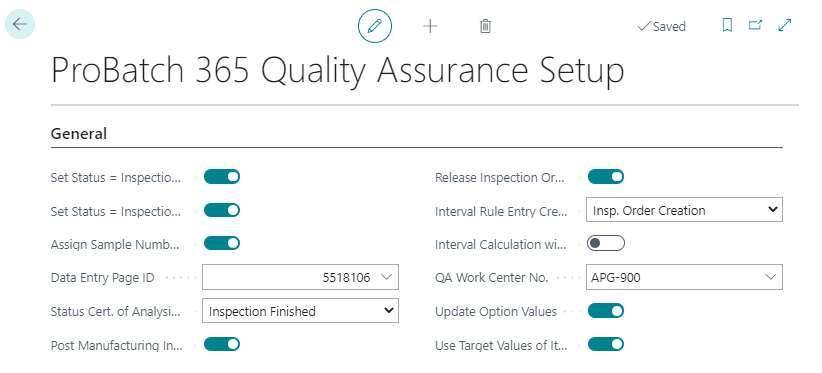

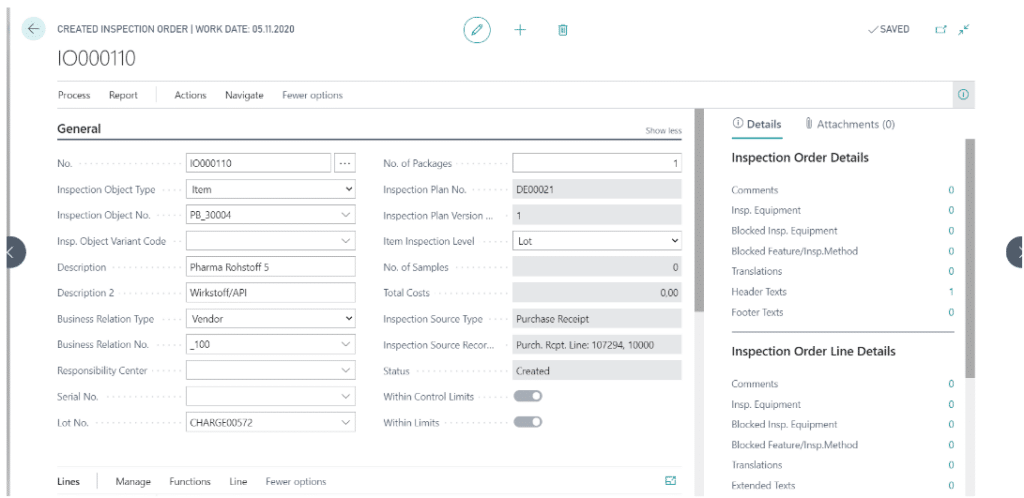

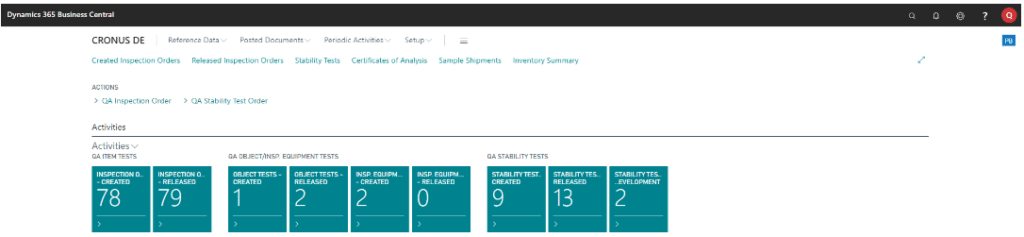

Quality assurance is critically reliant on the establishment and implementation of inspection plans, a process designed to track and assess inbound materials, ongoing work, and completed products. This process empowers manufacturers to document lot-specific variables, such as potency, concentration, or virulence. Integrating a quality module like YAVEON ProBatch into Dynamics 365 Business Central automates the process of placing lots on hold following a failed inspection. This guarantees only high-quality products advance to the subsequent stage.

This batch process manufacturing software also facilitates the creation of certificates of analysis and the establishment and implementation of long-term stability testing. These functions offer additional quality control measures, ensuring products adhere to the highest standards before market distribution. The system also supports the use of electronic signatures, introducing an element of accountability and traceability to the process.

Software Capabilities for Customized Inspection Plans and Sampling Techniques

The software's versatility enables the creation of customized inspection plans tailored to distinct items, equipment, or client/vendor specifications, ensuring each unique situation is duly addressed. It also accommodates various sampling techniques such as fixed quantity, per package calculation, and square root calculation for statistical sampling. This guarantees a comprehensive and precise inspection process.

Efficient Inventory Management: Inspection, Tracking, and Analysis

Upon completion of the inspection, the receipt is recorded, thereby updating the continuous inventory system. This action also triggers a warehouse put-away, which is currently not addressed. The inventory summary page then provides a comprehensive view of all inventory items, with visual cues to indicate each item's status. For example, an item under quality control or not yet released is marked in yellow. This system facilitates efficient inventory tracking and management, ensuring all items are accurately accounted for and their statuses are transparent.

The inspection process extends beyond this. An inspection order for the specific item, once released, is made available for the lab technician to conduct necessary tests. Upon completion of these tests, the inspection order can be closed, and the lot's status can be modified as needed. This can range from being blocked, requiring rework, being returned, or any other status. This method guarantees a thorough inspection and precise updating of the lot's status.

A standout feature of this process is the capability to generate a certificate of analysis. This document solidifies the inspection outcomes and can be printed for record-keeping purposes. Depending on the location of the inspection, this certificate could be issued for a customer, vendor, or shipment. It details the upper and lower tolerances and the target values, offering a complete summary of the inspection findings.

Trust Dynamics 365 Business Central and YAVEON ProBatch to Optimize Your Batch Manufacturing Processes

Achieving integrated quality for batch and process manufacturers is feasible through the strategic use of software solutions such as Business Central and YAVEON Pro Batch. These tools serve as one-stop solutions that assure quality at every stage of the process. They cover everything from the inception and implementation of inspection plans to the creation of analysis certificates and conducting long-term stability tests. By employing these tools, manufacturers can uphold the highest standards of quality, ensuring both customer satisfaction and regulatory compliance.

Moreover, the intricate process of receiving, inspecting, and managing inventory demands meticulousness and accuracy. The functionalities that allow recording visual value, updating the perpetual inventory system, and generating certificates of analysis are vital constituents of this procedure. By leveraging these capabilities, businesses can accurately account for, inspect, and manage their inventory, resulting in streamlined operations and superior customer service.

Here are some key takeaways:

- Integrated Quality Manufacturing: Dynamics 365 Business Central, powered by YAVEON ProBatch, offers a comprehensive financial and manufacturing solution suitable for various industries.

- Inspection Plans Execution: Users can set up and execute inspection plans for inbound materials, work in process, and finished goods. It can capture lot-specific variables such as potency, concentration, or virulence and automatically put lots on hold if they fail an inspection.

- Item Setup Demonstration: You can set up an item, assign features to that item, create an inspection plan, execute that inspection plan, generate a certificate of analysis, and explain how stability testing works. You can also utilize electronic signatures work, providing an additional layer of security and accountability.

- Compliance and Accountability: Compliance features with electronic signatures allow you to set rules around specific transactions and fields. This feature provides an audit trail of changes made, who made them, and when they were made.

- Stability Testing Features: You can perform stability tests, which allows for interval testing to check for degradation over time. This feature is particularly useful for industries where the longevity of a product's active ingredients is crucial.

Stoneridge Software is Your Batch Manufacturing Partner

We have a strong team of Dynamics 365 Business Central experts who can help you implement, support, and optimize your ERP system. We also work closely in partnership with YAVEON ProBatch and can help you utilize the integration between these two systems. Even in food production, maintaining strict quality controls is paramount – visit our Food & Beverage Manufacturing page to learn how Dynamics 365 ensures compliance and quality.

Get in touch with us to learn more.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.