Take Your Chemical Manufacturing Process to the Next Level with Dynamics 365 Business Central and YAVEON ProBatch

If you’re a chemical manufacturer already using Dynamics 365 Business Central, you know about the great features that help you do business better.

However, when you combine your system with YAVEON ProBatch 365, you get a robust collection of apps that will optimize your business processes and ensure you deliver high-quality products to your customers.

This is Part 1 of a two-part series on the combination of these solutions.

Monitor Your Products at Every Step of Your Business Process with YAVEON ProBatch for Dynamics 365 Business Central

If you are familiar with Dynamics 365 Business Central (BC), YAVEON ProBatch Quality Extensions look and act exactly like those in BC, so they should be very intuitive for your users.

Let’s look at some of these Quality Extensions and how they can help you.

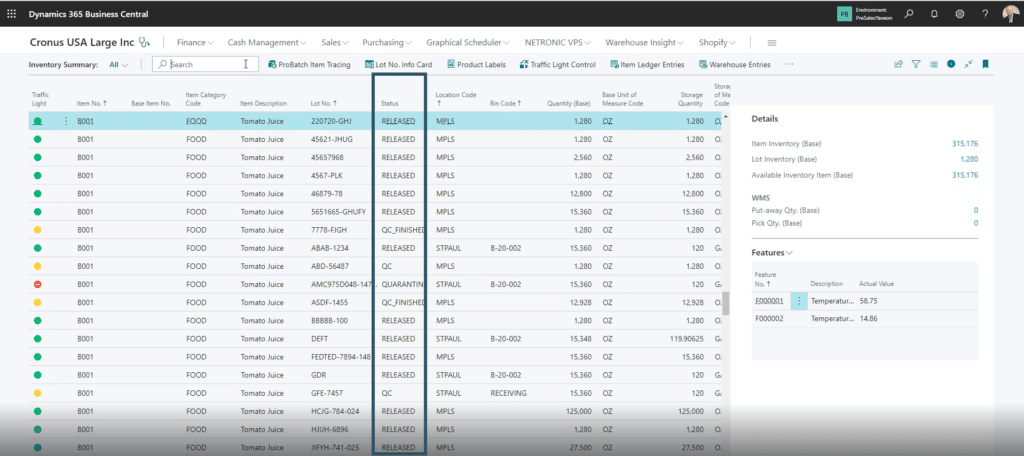

Lot Management and Posting Rules

Dynamics 365 Business Central comes with serialized and lot tracking out-of-the-box. YAVEON ProBatch brings additional functionality to this process by helping you manage the disposition of a lot and define posting rules.

Posting rules dictate when, where, and how you can use a particular lot based on its status, expiration date, or other characteristics you define.

We have identified two main areas in this field:

- Lot Status – This allows you to define the status of your lot based on your business process and the terminology you use. You can also create rules around the status itself. In our example, we have it set up so when an item is put into inventory it will automatically be updated to quarantine status. This means the lot is unusable in the system until it goes through the necessary steps to be ready for production

- Status Types – You will want to define these based on your terminology as they help you determine where your lot is in its lifecycle process. For this example we have:

- Quarantine – It has been received but still has to pass safety/quality inspections

- QC_Finished – The quality team is done looking at it, but you might need to send it out to an outside inspector for specific parts

- QC - This is an intermediary status noting that the QC process is finished but the product is still awaiting final approval

- Released – This means the lot has passed all inspections and is ready to enter your manufacturing process

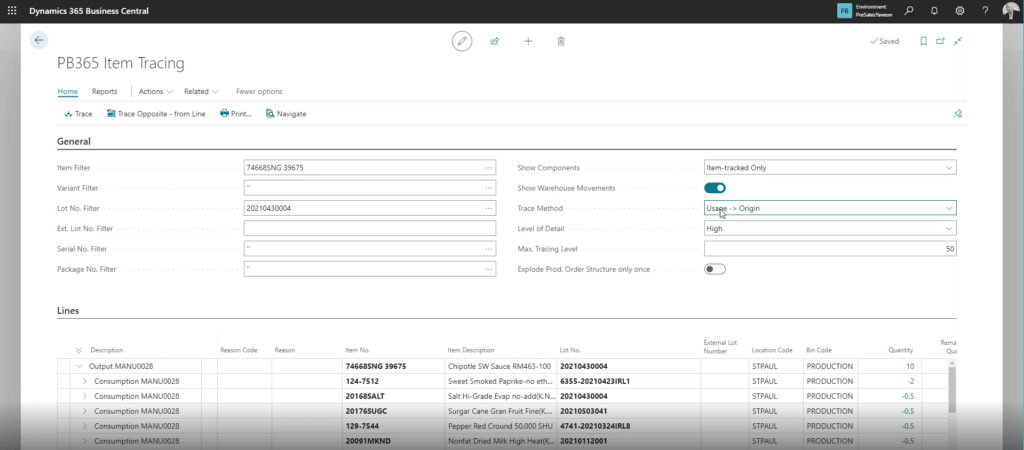

Item Tracing

This feature lets you look at a series of consumption records to see the raw material inputs into the finished goods. For example, if you have a lot that spoils you can track the specific individuals who had contact with it, what stage the issue happened at, where it happened, and the date and time of the problem. This way you know who to talk to if something goes wrong.

There are two trace methods:

- Usage to Origin – Traces the item from finished output to its origin in your production process

- Origin to Usage – Traces the item from your inbound purchase order to its being consumed into your process

You can also utilize the Packaged Tracking feature, which lets you track products based on the package or serial numbers associated with them.

If you have a pallet full of multiple units of a specific product, you can also use Load Carrier Tracking at the lot level.

Ensure You’re Getting Quality Products to Your Customers

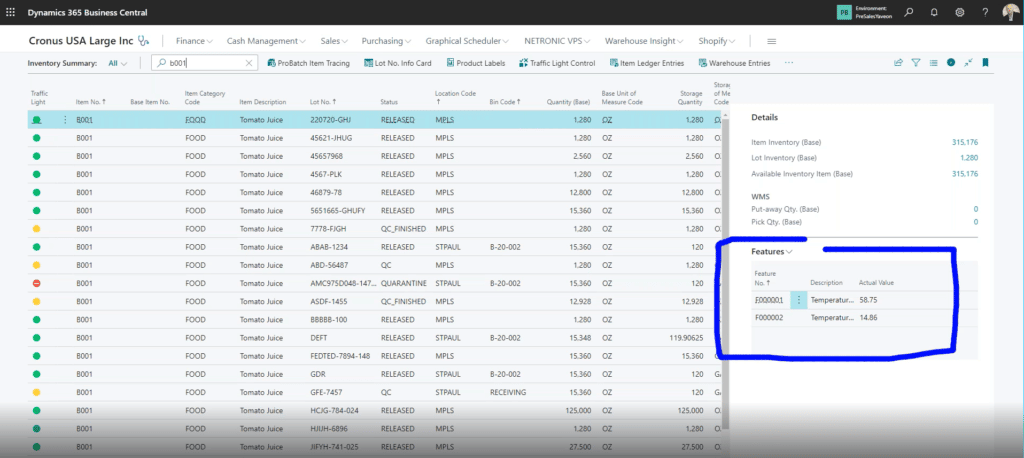

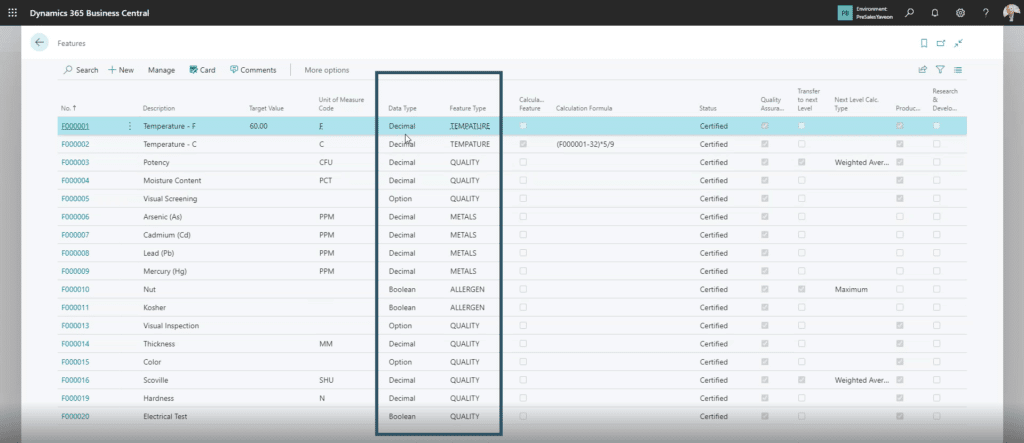

There are a lot of features you can use to define the characteristics you want to place on the quality inspection of an item.

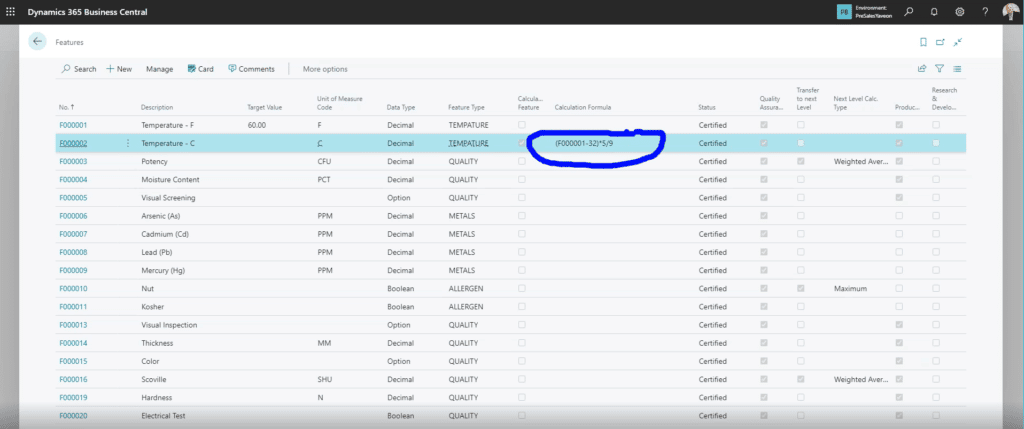

Features are values and measurements you place on an item to make sure it’s ready to go to market. In our example, we are going to use the temperature of a chemical substance.

There are a lot of data types and feature types you can track in your system to ensure your products are ready to go to market. Below are some examples of each:

- Data Types - Decimal, Option, Boolean, etc.

- Feature Types - Temperature, Quality, Metals, Allergen, etc.

You can also define the description, target value, and unit of measure code applicable to your product, as you can see in the photo above.

There are also extended features that allow you to be a bit more specific:

Calculation Formula

If you want to take several different features or samples to ensure a product is ready, you can combine them to produce an additional feature that gives you an average score. For example, if you are scoring four samples from one batch on a scale of 1-10, and 8 is a passing grade, the program will calculate the average score of those features to see if it meets your threshold.

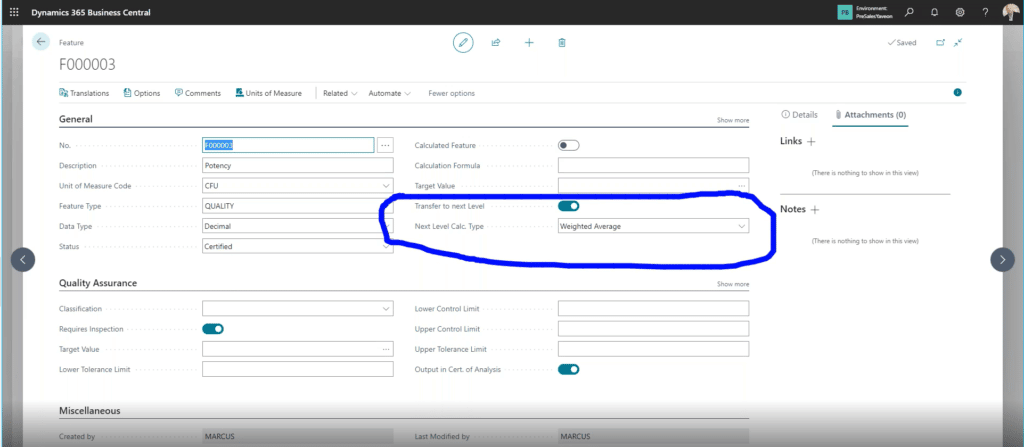

Transfer Values

Transferring values during the manufacturing process allows you to track those values every step of the way. For example, if you were measuring the potency of a chemical, you can use various Next Level Calculation types to get an average number at each stage to ensure it stays within your set value.

The Next Level Calculation Types include:

- Additive

- Average

- Minimum

- Maximum

- Weighted Average

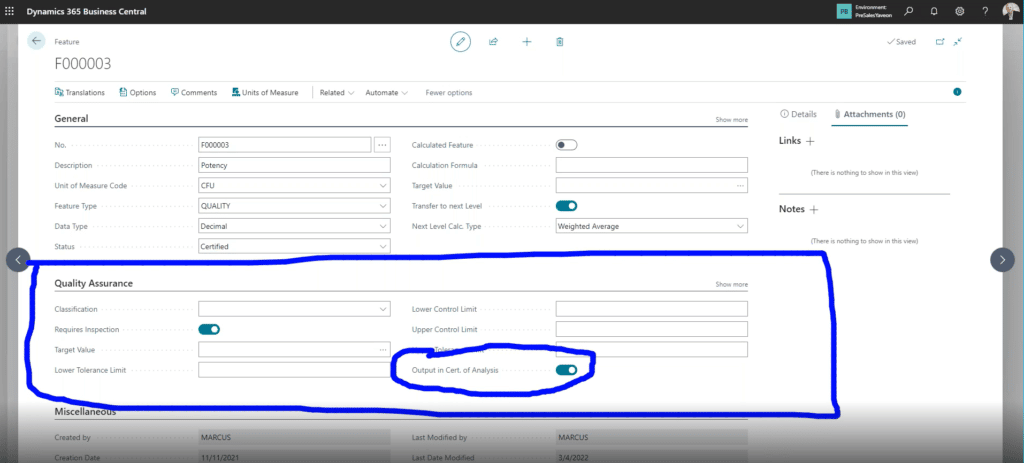

Quality Assurance

This lets you take a specific feature value and output that on the certificate of analysis. That certificate and the detail you attach to it, serve as a reassurance to your client that your company has taken all the necessary steps to make sure their product is safe and ready for market.

Stay Tuned for Part 2!

In Part 2, we will take you through a detailed look at these features and how you can configure them to conduct a quality assessment that fits your business process.

Questions?

Please reach out to us! We have a team of Dynamics 365 and YAVEON ProBatch experts ready to help.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.