Modernize Your Manufacturing Processes with Dynamics 365 ERP Solutions

Manufacturing has come a long way, from paper-based tracking and whiteboards to on-premises ERP systems and now intelligent, cloud-based platforms.

While the technology has evolved, many manufacturers are still stuck in the mud with manual processes, disconnected systems, and spreadsheets that were never designed to scale.

In this blog, we will talk about the real cost of manual workflows by looking at common challenges manufacturers face in a quickly evolving technology landscape, how smart cloud solutions like Dynamics 365 can help, and how you can lead your business through an effective and efficient digital transformation.

Keep reading or watch the video to see the benefits of modern manufacturing systems.

The Hazards and Costs of Manual Workflows

In a world where AI is increasingly automating tasks and boosting efficiency, manual processes slow your organization down, quietly eroding margins, increasing risk, and limiting visibility when you need it the most. This dangerous combination makes it harder for you to make smart decisions on time.

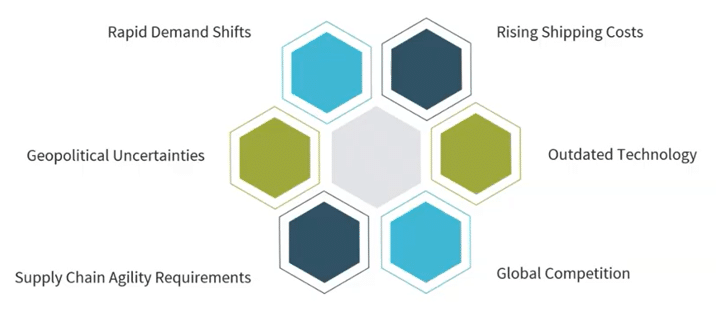

Manufacturers today face rapid shifts in demand, geopolitical uncertainty, rising costs, global competition, and supply chain volatility. Given these issues, relying on disconnected spreadsheets and old systems can lead to serious problems:

- 62 percent of manufacturers cite disconnected data as a growth barrier

- Manual systems reduce margins by 20 percent

- Organizations lose 30 percent of their time to manual processes

- The cost-per-order – when managed manually – is 25 percent higher

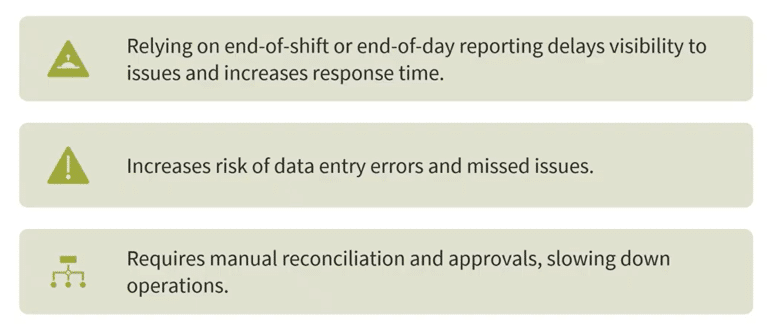

Common symptoms of manual workflow inefficiencies that negatively impact your bottom line include:

- Operational costs: Errors and rework, duplicate work, and other manual tasks lead to slower production cycles.

- Inventory costs: Excess inventory, stockouts, and carrying costs can slow production and clog up your warehouse.

- Labor costs: Defective products, unnecessary training and onboarding force your team to spend valuable hours on tasks that don’t drive business.

- Quality and compliance costs: Humans make mistakes and oversights happen from time to time when doing inspections. These costly errors can lead to defective products, missed opportunities, and a strategic disadvantage if you are not compliant with regulatory requirements.

- IT and data costs: Fragmented or siloed data, manual reporting, and integration limitations break up your system into disconnected parts, leading to higher IT maintenance costs.

Perhaps the highest cost to old and outdated systems is that all of the costs above lead to poor performance, which can lead to significant customer satisfaction costs. If your business is not operating at a rate that allows you to keep your customers happy and bring in new ones, it will be hard to continue operating without a solution.

Real-World Example

A manufacturer that was managing production schedules on a whiteboard and tracking inventory in Excel ran into significant challenges with that system. Despite the system working initially, they eventually ran into major roadblocks:

- The system was prone to errors and oversights

- It became difficult to optimize capacity

- Production data became outdated

- They couldn’t track real-time progress against their plan

- It was difficult to communicate the plan with stakeholders due to fragmented data

After implementing Dynamics 365, the client reported a 15 percent reduction in downtime and a 20 percent increase in improved on-time delivery.

Replacing Spreadsheets – How Dynamics 365 Integrates Finance, Operations, and Reporting

Despite legacy challenges that come with using spreadsheets, many users like to maintain the functionality within Excel that they are used to. With Dynamics 365, you can do just that with an embedded integration and validation for Excel. This means you can upload your data into an organized and centralized Dynamics 365 system, export it to Excel to complete your work, and import it right back into the system without skipping a beat.

Dynamics 365 replaces fragmented tools with integrated, cloud-based ERP and CRM platforms that connect:

- Finance and accounting

- Manufacturing and operations

- Supply chain and procurement

- Sales and customer service

- Reporting and analytics

Built on Microsoft Azure, Dynamics 365 offers secure, scalable growth without the burden of managing IT changes or buying and maintaining costly servers. Additionally, built-in integrations with Microsoft 365 tools like Outlook, Excel, Word, SharePoint, and Microsoft Teams allow teams to collaborate seamlessly while working from a single source of truth.

Automated Workflows and Real-Time Insights That Drive Better Decisions and Save Time

With Dynamics 365, manufacturers gain:

- Automated workflows that reduce repetitive tasks through Power Automate

- Built-in validation for accurate data import and export

- Customizable, real-time dashboards for performance monitoring through Power BI

- Immediate access to operational and financial data

Instead of waiting for end-of-day or month-end reports, leaders can see what’s happening now and act before small issues become costly problems. Replacing reactive decisions with proactive decisions will pay huge dividends for your business.

Streamlining Core Manufacturing Processes

Within Dynamics 365 ERP solutions, manufacturers can manage:

- Production orders for detailed planning and execution

- Multi-level bills of materials for accurate costing

- Routing and capacity planning to reduce bottlenecks

- Assembly management integrated with inventory and finance

Procurement and scheduling are automated to align supply with demand, while quality control features block defective items, track lot and serial numbers, and support regulatory compliance.

For organizations leveraging Manufacturing Execution and Evaluation Systems (MEES), real-time shop floor data captures time, attendance, consumption, and output—improving traceability and reducing manual data entry.

Dynamics 365 Solutions – ERP Options for Small, Midsize, and Enterprise Manufacturers

With Dynamics 365, two flexible ERP solutions are specifically designed to meet manufacturers where they are today and scale as they grow.

Dynamics 365 Business Central for Small and Midsize Manufacturers

Dynamics 365 Business Central is ideal for small and midsize manufacturers looking for a single system to manage financials, inventory, purchasing, and production. Key benefits include:

- Real-time dashboards for end-to-end visibility across operations

- Flexible deployment (cloud, on-premises, or hybrid)

- Faster access to insights without waiting for the month-end close

- Automated production orders and material planning

- Unified financials, inventory, and production management

- Integrated quality control and lot tracking

Business Central also integrates seamlessly with Microsoft Power Platform, enabling manufacturers to:

- Use Power Automate for approvals and workflows

- Visualize KPIs with Power BI

- Build custom Power Apps, such as shop-floor downtime tracking tools

Where Business Central might lack is when it comes to more complex or customized manufacturing features. In this, you can extend it with additional tools like YAVEON 365 to meet those needs.

Dynamics 365 Finance & Supply Chain Management (Formerly Operations) for Complex and Global Operations

For larger or more complex manufacturers, Dynamics 365 Finance and Supply Chain Management delivers advanced capabilities, including:

- Sophisticated production scheduling and resource planning

- Multi-site and global operations management

- Embedded AI-driven demand forecasting

- Predictive maintenance to reduce downtime

- A strong integration with the Power Platform, like in Business Central

In one example, a discrete manufacturer operating across three countries used Dynamics 365 to coordinate production schedules, manage cross-border inventory, and automate procurement. Predictive analytics reduced downtime by nearly 20%, demonstrating the power of a fully connected system.

Essentially, Finance and Supply Chain Management encompasses all the functionality of Business Central without having to integrate an additional solution.

Dynamics 365 Customer Engagement: Smart CRM for Manufacturers

The Dynamics 365 suite of solutions also includes several CRM solutions that can help manufacturers modernize and improve operations. This includes:

Dynamics 365 Sales

- Unifies CRM and ERP data to give sales teams real-time visibility into pricing, inventory, and delivery timelines

- Improves forecasting accuracy and deal prioritization using AI-driven insights

- Enables tighter collaboration between sales, production, and supply chain to reduce order errors and delays

Dynamics 365 Customer Service

- Centralizes customer, product, and asset data to resolve issues faster

- Supports proactive service with AI-powered case routing and knowledge recommendations

- Helps manufacturers shift from reactive support to value-added service experiences

Dynamics 365 Field Service

- Enables predictive and preventative maintenance using IoT and asset data

- Optimizes scheduling and dispatch for technicians to reduce downtime

- Improves first-time fix rates with mobile tools, work orders, and real-time parts visibility

Dynamics 365 Customer Insights - Data

- Creates a unified, real-time view of customers across sales, service, and operations

- Uses AI to surface trends, churn risks, and cross-sell opportunities

- Helps manufacturers personalize engagement across the full customer lifecycle

Dynamics 365 Customer Insights – Journeys (Formerly Marketing)

- Aligns marketing with sales and service through shared customer data

- Automates targeted, account-based marketing campaigns for long sales cycles

- Improves demand generation and customer retention with data-driven engagement

Compliance, Sustainability, and Customer Engagement

Dynamics 365 includes built-in tools to support regulatory compliance (ISO, FDA, OSHA) and sustainability initiatives. Digital audit trails and sustainability dashboards help manufacturers track waste, carbon footprint, and ESG goals with confidence.

AI in Manufacturing – Microsoft Copilot’s Capabilities and Business Impact

AI in manufacturing is here, and it is delivering real value to organizations in various sectors already. With AI-powered analytics and Microsoft Copilot embedded directly into Dynamics 365, manufacturers can:

- Forecast demand and capacity more accurately with predictive analytics

- Automate and optimize route planning to account for traffic, weather, and delivery windows in real time

- Predict maintenance needs before failures occur through IoT machine sensor data

- Identify quality issues earlier in the process and respond to them quickly

- Automate routine procurement, order entry, and reconciliation

- Consolidate and automate data search efforts, as AI can pull in data from multiple sources and provide them into a single dashboard

Copilot allows users to ask questions in plain language, such as “Which suppliers are at risk this week?” and receive actionable insights and recommended next steps. This dramatically improving decision speed and accuracy.

The Rise of Agentic AI

Within Dynamics 365, specific agents with industry-specific roles are becoming more common and available to use, such as the account reconciliation agent or the supplier communications agent.

With Microsoft Copilot Studio, you can also create your own agents that serve your business's unique needs.

Measurable Results with AI

According to IDC research referenced in the session, organizations using AI-powered Dynamics 365 solutions achieved:

- 27% more manufacturing process automation

- 20% productivity improvement across supply chain, procurement, and inventory teams

Predictive maintenance alone can save millions annually for large manufacturers by reducing unplanned downtime and extending equipment life.

Modernization Process – From Roadmap to Results

Technology alone does not guarantee success. Digital transformation requires people, process, and platform alignment.

Common Pitfalls to Avoid

Many modernization initiatives struggle because organizations:

- Underestimate the importance of people-focused change management

- Skip process review and documentation

- Fail to clean and optimize their data for migration and integration

- Lack of executive sponsorship

Addressing these areas early reduces risk, controls costs, and improves adoption.

The Importance of a Clear Roadmap

For many manufacturers, the first step is a roadmap or discovery workshop. This process evaluates current systems, identifies bottlenecks, and defines a clear, phased path to the cloud.

Each organization’s roadmap will look different based on unique needs and goals. The Stoneridge team will meet with you and your team to collaboratively understand how Dynamics 365 cloud-based technologies (and other tools within the Microsoft stack) can solve your business challenges and help you thrive.

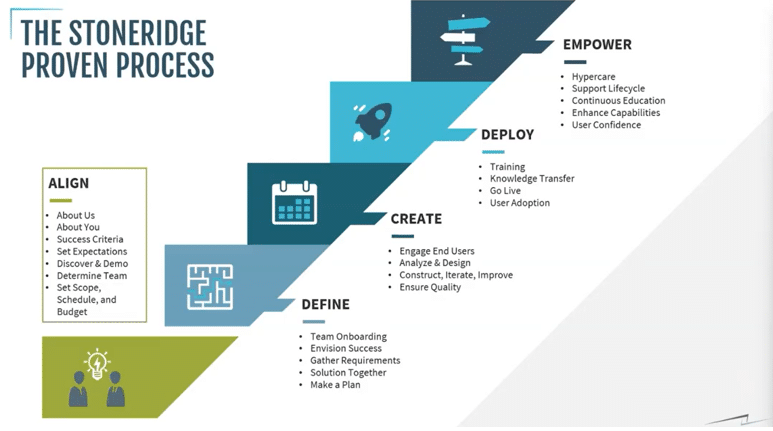

The Stoneridge Proven Process

Stoneridge Software’s proven methodology supports long-term success through five key phases:

- Align – Understand challenges, define partnership, and shape the project

- Define – Validate scope, prepare teams, and design the solution

- Create – Build the system and prepare the organization to own it

- Deploy – Train users, go live, and ensure readiness

- Empower – Stabilize operations and transition to ongoing support

This structured approach ensures modernization is not overwhelming—and that improvements continue long after go-live.

Ready to Modernize Your Manufacturing Processes?

Connect with the Stoneridge Software experts today to explore how Microsoft Dynamics 365 can help you improve visibility, efficiency, and profitability—today and into the future.

Under the terms of this license, you are authorized to share and redistribute the content across various mediums, subject to adherence to the specified conditions: you must provide proper attribution to Stoneridge as the original creator in a manner that does not imply their endorsement of your use, the material is to be utilized solely for non-commercial purposes, and alterations, modifications, or derivative works based on the original material are strictly prohibited.

Responsibility rests with the licensee to ensure that their use of the material does not violate any other rights.